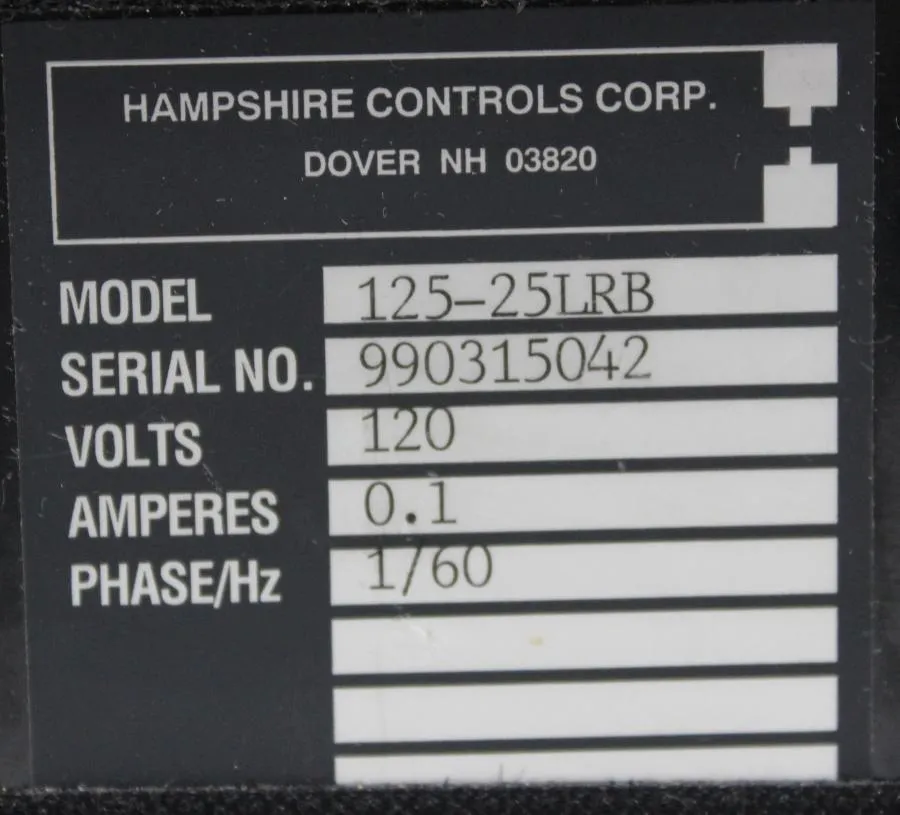

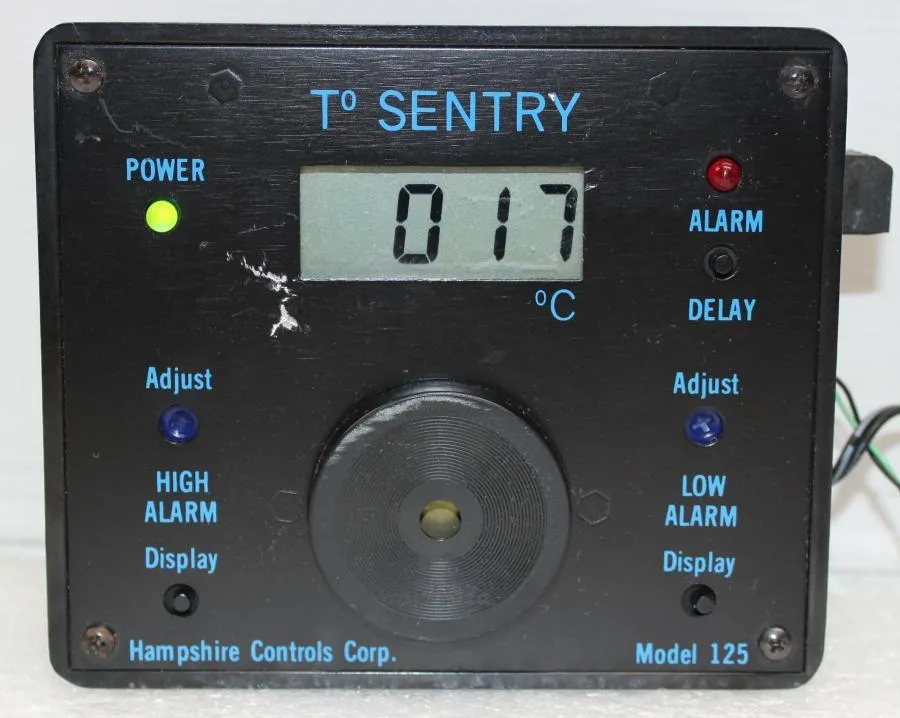

Hampshire Controls 125 Temperature Sentry 125-25LRB w/Power Supply

sku: 3347363

Out Of Stock

Condition :

Pre-owned

Warranty :

30-Day Warranty, 100% Parts and Labor

Region :

US

$25.00$79.00

Apply For Finance

Make Offer

Enquiry Here

- Make Hampshire Controls Corp

- Model Hampshire Controls 125 Temperature Sentry 125-25LRB w/Power Supply

- Serial 330315042

- Weight 12

- Voltage 120V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 12×12×13 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

Hampshire Controls 125 Temperature Sentry 125-25LRB w/Power Supply

- Hampshire Controls

- 125 Temperature Sentry

- Model: 125-25LRB

- Serial No.: 990315042

General Model 125 Information

A.

The Sensor Probe

The sensor supplied with the Model 125 is a highly accurate integrated circuit temperature sensor, encapsulated in epoxy resin with PVC or Teflon insulated wire. The PVC may be used in air, water, or other mild aqueous solutions, from the ice point to +125° C. At very low temperatures the probe lead wire should be Teflon, because the PVC may will become brittle and crack, allowing the entry of moisture or ice.

NOTE: Immersion in solvents and harsh chemicals must be avoided. Use of protective thermowells when monitoring such materials is required.

If the unit is senses an input that is out of the specified range, it will give a large negative reading (ex. -450), and the alarm will go on. Pressing the delay button will force the display to show the actual temperature reading. For instance, a unit with upper range of 25 ° C will go out of range if the probe reads 50 °C. If the display shows a continuous reading of a very low number (ex. -450) that is an indication of a failed probe, or a broken probe lead. If the display shows a continuous reading of a very high number, or is offscale high, that is an indication of a shorted probe, or a shorted probe lead. Replace probe and recalibrate unit.

B.

Installation

The probe may be used in air or simulated product, provided that the product does not contain solvents or reagents that attack polyvinyl or epoxy. (See Sec.A) If the sensor is to be installed in a refrigerator, it is recommended that the probe be place in a water and glycol chlorine solution to keep bacteria from forming. If the sensor is to be used in a cabinet or enclosure, particularly freezers, it is important that good techniques be employed to prevent migration of room moisture into the cabinet. Whenever possible, the probe should be installed through an existing access port provided by the manufacturer and then the port should be resealed.

Alternatively the probe can be run under, over, or through the door sealing gasket. Often a door gasket will have a joint at one or more corners. One technique is to open that joint slightly by carefully making a slit with a razor blade and inserting the flat probe wire and then resealing the joint with flexible silicone sealing compound. Inside the cabinet, the probe wire should be run so that it will not become snagged during loading, unloading or cleaning procedures and suffer possible physical damage.

C.

Sensor Location The sensor should be installed to respond to the average temperature of the space being monitored and not to local conditions caused by door openings etc. The object is to provide a certain amount of safety for the area being monitored without generating "false" or nuisance alarms. For example, locating the sensor probe on the bottom of a chest freezer will result in the alarm being sounded later than if it was located near the top. However, locating the sensor too close to the top of the chest freezer could result in the alarm being sounded due to routine lid opening. It is wise to choose a location that offers the degree of safety that is desired for the enclosure contents.

D.

Display Interpretation

Digital devices generally do not "round off". In the case of temperature monitors, a display that reports a value of 10 deg. can represent any temperature from 10.0 to 10.9 degrees. Therefore, a very small system change (0.1 deg. or less) or minor electronic disturbance may cause the displayed temperature to change one digit.

Only when the displayed temperature is changing with a period of greater than 20 seconds, can the change be related to real thermal changes in the space being monitored.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”