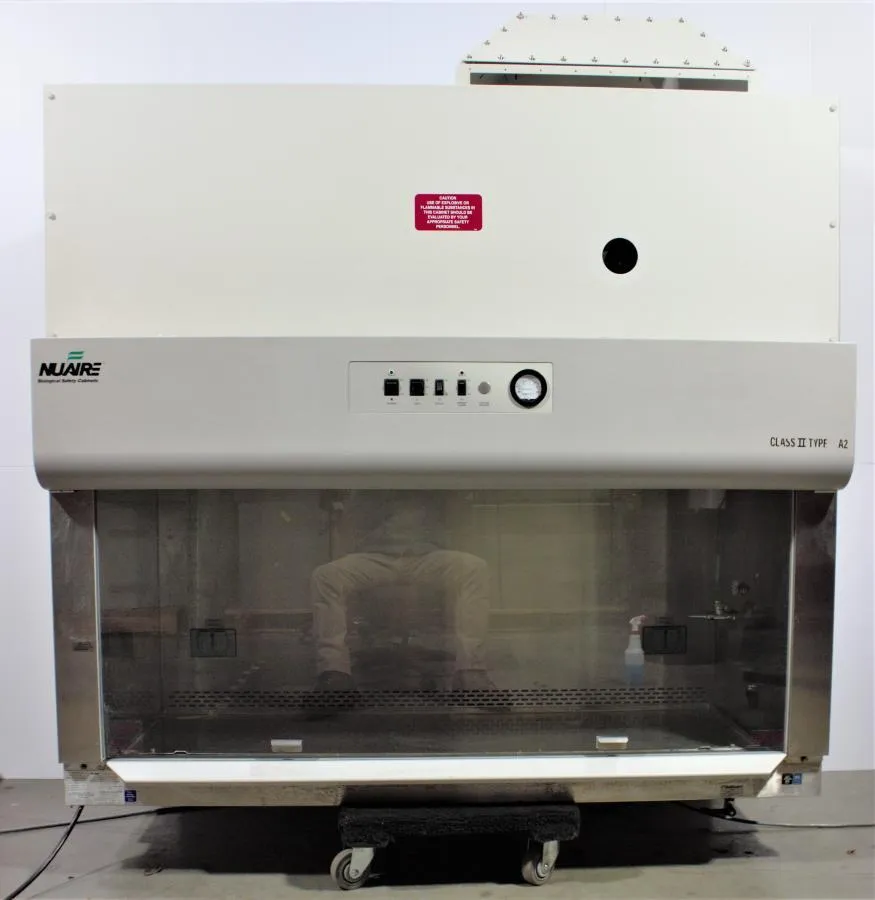

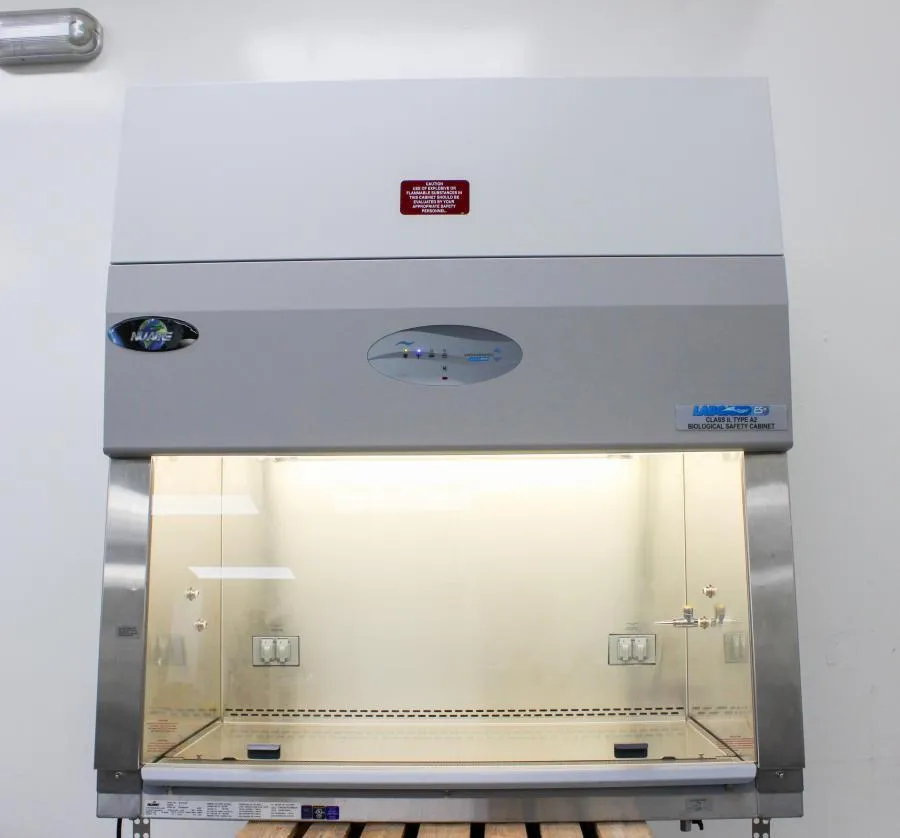

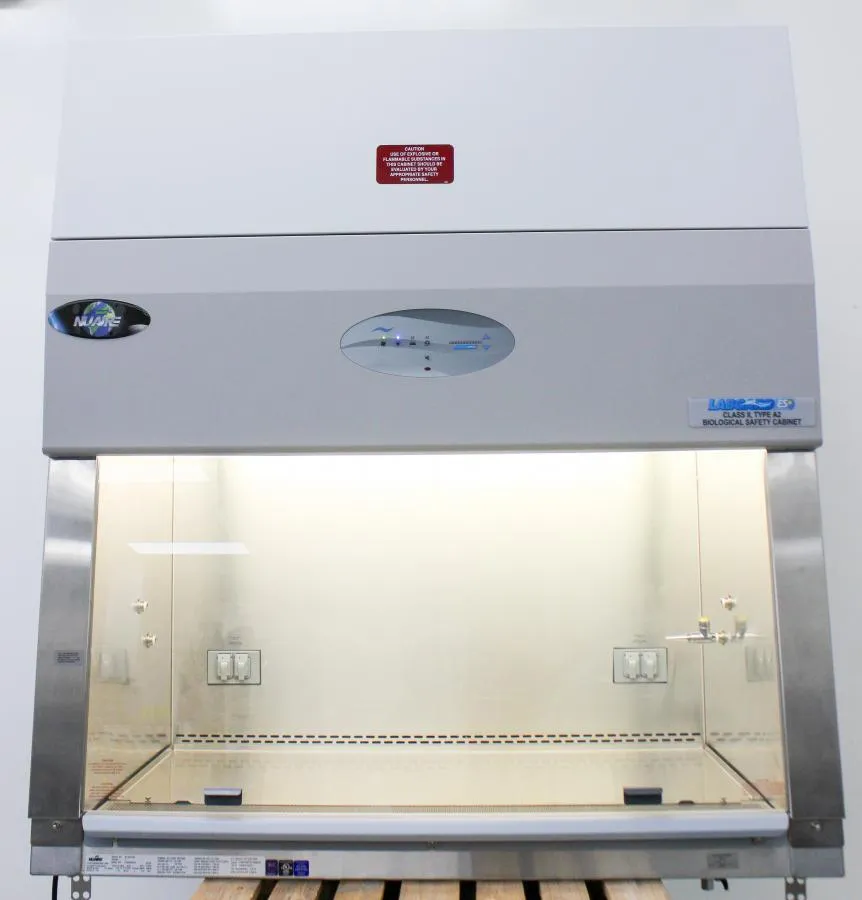

NuAire LabGard ES Class II, Type A2 Biological Safety Cabinet NU-540-400

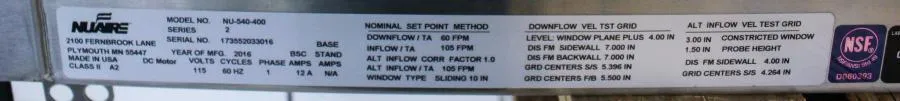

- Make NuAire

- Hertz 60Hz

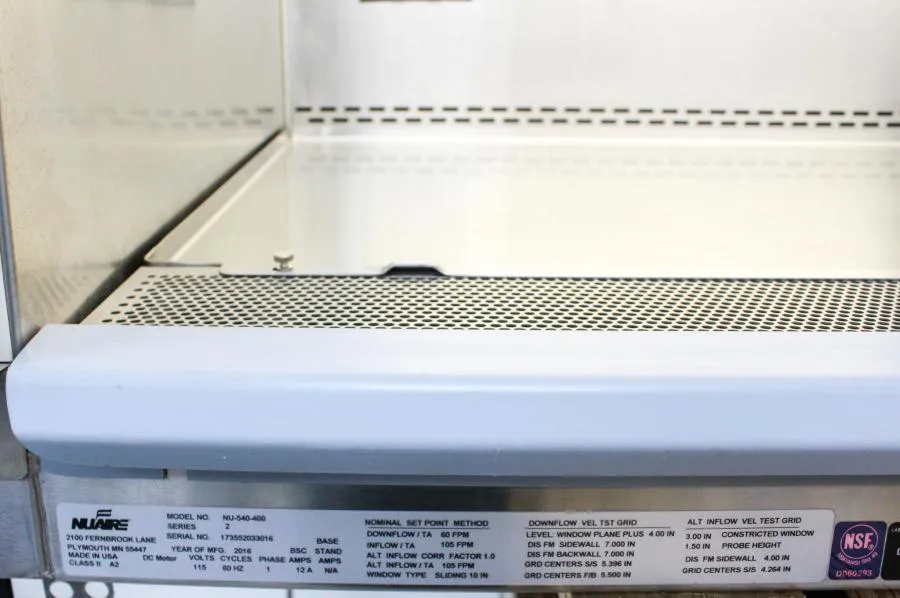

- Model NU-540-400

- Serial 173552033016

- Weight 505

- Voltage 120V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 36×58×70 in

- Shipping Type Freight

- Item Condition Pre-owned

- Manufacturing Date 2016

NuAire LabGard ES Class II, Type A2 Biological Safety Cabinet NU-540-400

***LabGard BSC is preowned with minimal wear from normal use. UV, lights, blower all working. Unit does not include base stand. 30-day warranty included with purchase. See photos for details.

The NU-540 integrates a powerful DC ECM motor with flexible plenum into a robust steel structure to provide long-term, cost effective containment configured for basic research and clinical applications.

The NU-540 features a DC ECM motor to economize energy while distributing laminar airflow through a flexible plenum and offering enough power to overcome HEPA filter loading and minimize filter changes. This design provides the user with a work zone whose side and back walls are constructed from a single piece of stainless steel for enhanced containment and easy cleanability. Fluorescent lighting illuminates the procedure inside the cabinet while a dished work tray traps liquid spills and a cord-pass through in the side wall facilitates the use of small electrical devices in the work area. Users easily monitor cabinet performance through the Aeromax™ control system that displays the pressure in the cabinet’s internal airflow plenum. The NU-540 is configured to meet the needs of most clinical and research applications, offering containment that meets the NSF/ANSI 49 standard that is followed in most of the Americas.

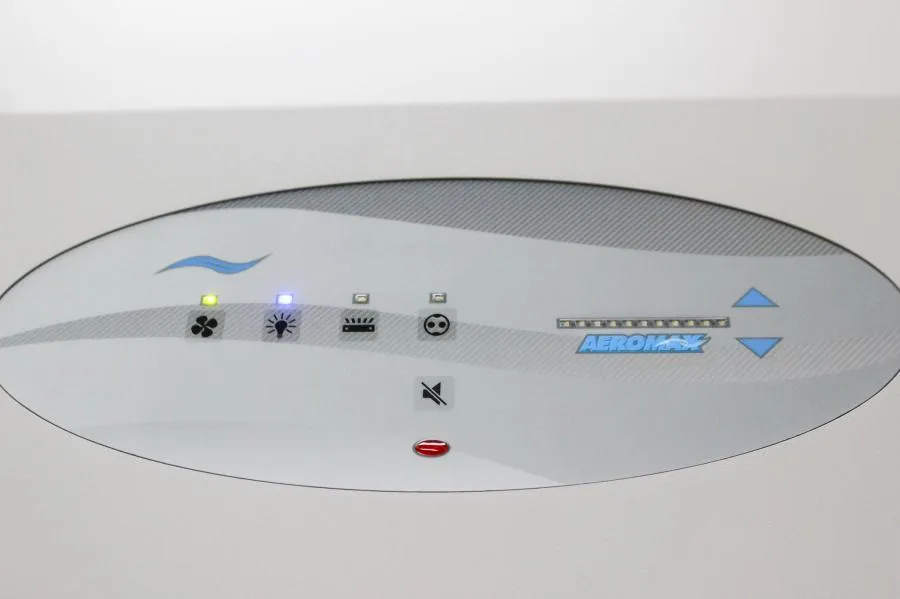

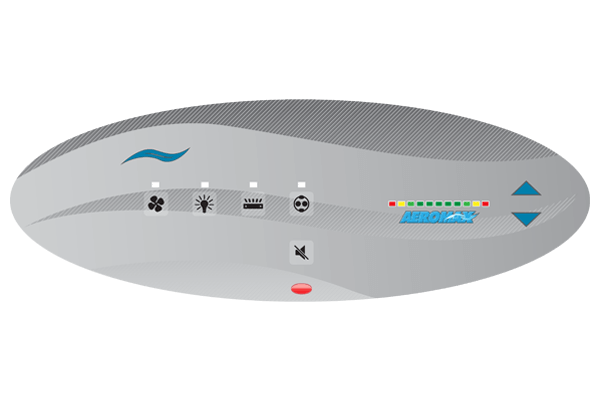

AeroMax Control System

The AeroMax control system visualizes airflow plenum pressure through a series of multicolored lights and activates both an audible and visual alarm whenever cabinet performance departs from normal parameters.

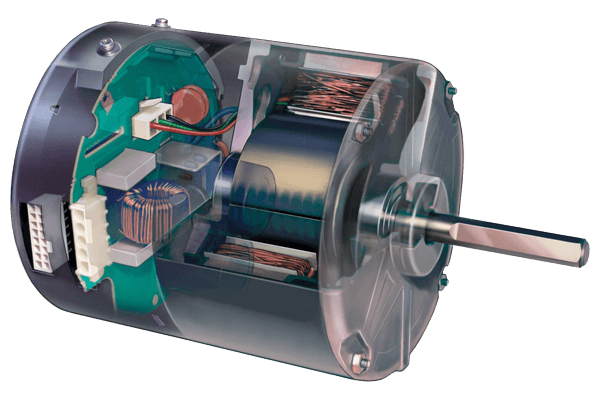

Ultra High Efficiency Motor

A single DC ECM motor with a precision-engineered forward curved fan powers airflow through the biosafety cabinet. The ultra-high efficiency motor lowers energy costs and reduces noise pollution but is powerful enough to extend filter life. The one motor design allows for easy certification and airflow balancing. In addition, it provides enough power to compensate for HEPA filter loading, reducing filter changes and lowering the total ownership cost.

HEPEX Zero Leak Airflow System

Our signature flexible plenum design complements the ultra-high efficiency motor to uniformly distribute the downflow air across the supply HEPA filter into the work zone in a laminar or unidirectional pattern. The flexible plenum insulates the transmission path of any vibration and noise produced by the motor blower protecting sensitive cells and reducing noise pollution. The HEPEX material is tear and abrasion-resistant, flame retardant, and impermeable to gases, fluids, and dust reducing contamination risks making it the perfect solution for biomedical/microbiological and hazardous drug compounding work. All filter seals are kept under negative pressure. In the event of a potential leak, air will recirculate back through the motor blower and into the plenum.

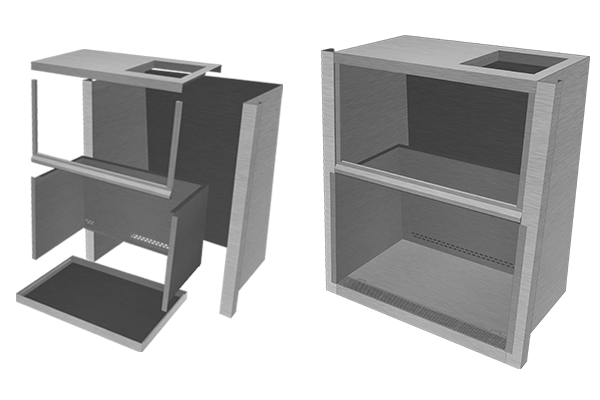

Monolithic Construction

At the heart of any NuAire biosafety cabinet is its construction. The NuAire design centers on the use of high-quality stainless steel and seam welding to eliminate leak risks that come with the use of multi-piece shells put together with gaskets, sealants, and rivets. The NuAire BSC uses a coved stainless steel interior inserted into a larger wrap that makes up the cabinet walls. The top and bottom catch tray is seam welded into place, creating a monolithic leak-free cabinet shell designed to provide long-lasting maximum safety.

| Blower Contact Wires | Optional |

| Closure Panels | Optional Rear Closure Panels for Seismic Brackets |

| Cord Pass Through | Standard Right, Optional Left |

| Double Exhaust HEPA Filter | N/A |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | Optional |

| Magnifying Glass in Window | N/A |

| Motorized Base Stand | Optional as Separate Accessory |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | Standard, two backwall |

| Plumbing | Optional 3/8" Soft Copper, 3/8" Black Pipe (Gas Only), or 1/2" Rigid Copper |

| Remote Service Valves | N/A |

| Seismic Brackets or Studs | Optional Rear or Floor Mount Seismic Brackets |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Side Panels | Optional with Plumbing out Bottom, Top or Back |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | Optional |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Tempered |

| Armrest | Standard Plastic with Optional Stainless Steel |

| Cabinet Construction | All welded stainless steel 16/18 GA, Type 304 pressure tight design |

| Casters | N/A |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 6-inch (152 mm) 99.99% Efficiency on 0.3 microns |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1/2 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | N/A |

| Style | Bench top, optional base stand |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 21 (533) open to fully closed |

| Work Access Opening(s) | 8, 10-inch (203, 254 mm) |

| Work Surface | One-Piece Dished Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232 |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 71 (1803) |

| Est. Shipping Width Inches (mm) | 59 (1499) |

| Exterior Depth Inches (mm) | 32 1/8 (817) |

| Exterior Depth with Armrest Removed Inches (mm) | 31 7/16 (799) |

| Exterior Height (Minimum for Transport) Inches (mm) | 59 (1499) |

| Exterior Height Inches (mm) | 60 7/8 (1546) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 87.375 (2219) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 93.375 (2371) |

| Exterior Width Inches (mm) | 53 5/8 (1362) |

| Nominal Width Feet (Meters) | 4 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 45 7/8 (1165) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | 25 3/4 (654) |

| Work Area Depth Measured at 12-inches (305 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 14-inches (356 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | Inquire |

| Work Area Height Inches (mm) | 28 1/2 (724) |

| Work Area Width Inches (mm) | 46 3/8 (1178) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | 2.9 |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [14-inch (356mm) Access Opening] | |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 2.6 |

| Electrical Configuration | 115V60Hz |

| Junction Box | Optional |

| Outlet Amps | 3 |

| Power Cord | Single 12-foot (3.7 m) 14 GA - 3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 12 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 56 dba |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 426 (724) |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 363-588 (617-1000) |

| 12-inch (305 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 14-inch (356mm) Opening Exhaust Requirement for Fixed Canopy (NU-926) CFM(CMH) | N/A |

| 14-inch (356mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM(CMH) | N/A |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 359 (610) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 295-520 (502-884) |

| Bag In Bag Out | N/A |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | 1140 |

| Heat Rejected 12-inch (305 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 14-inch (356 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | 1020 |

| Heat Rejected Vented (BTU/Hour) | 157 |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Pressure |

| Control System | AeroMax |

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”