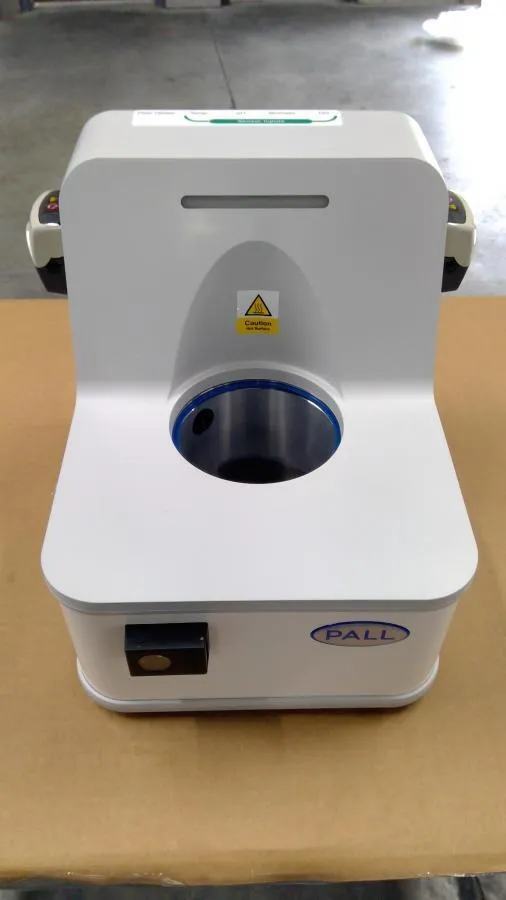

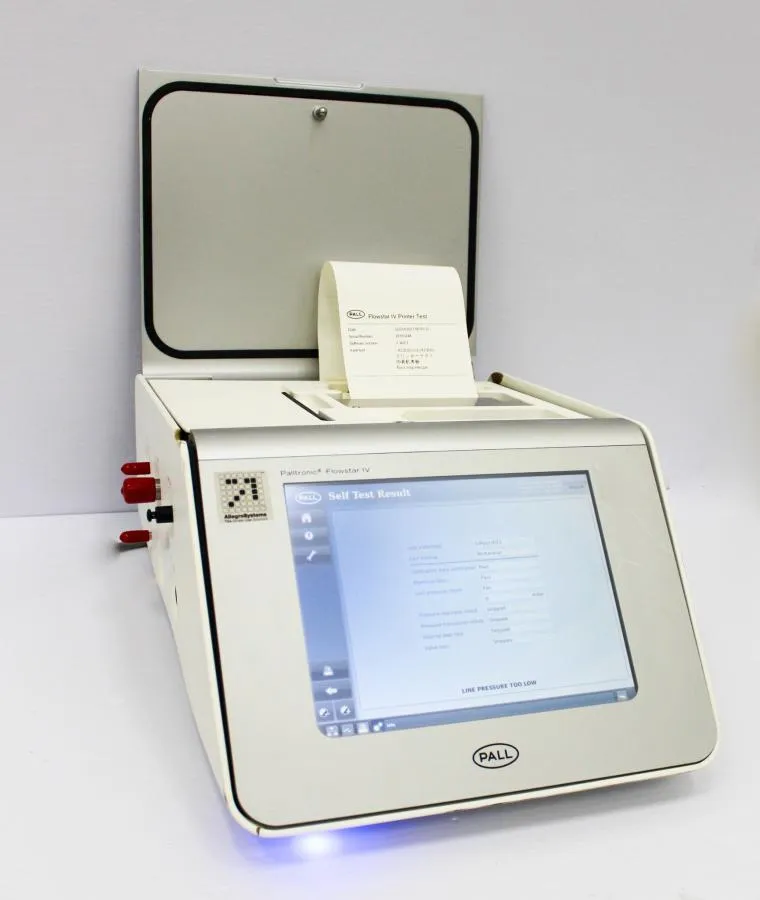

Pall Allegro TK8 3D 200L Biocontainers Standard CLEARANCE! As-Is

- Make Pall

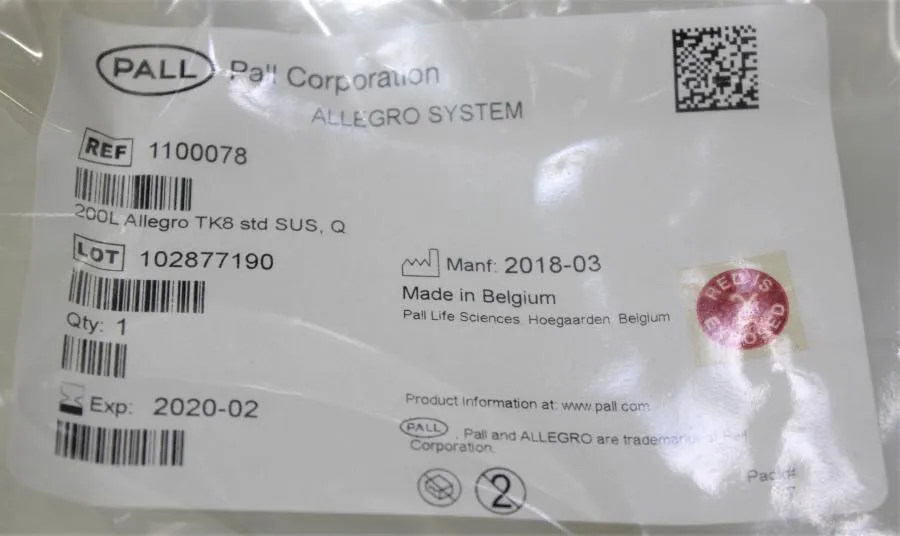

- Model Allegro TK8 3D 200L Biocontainers Standard Systems 1100078

- Serial N/A

- Weight 40

- Working Working

- Warranty AS-IS

- Dimensions 35×51×17 in

- Shipping Type Freight

- Item Condition New other (see details)

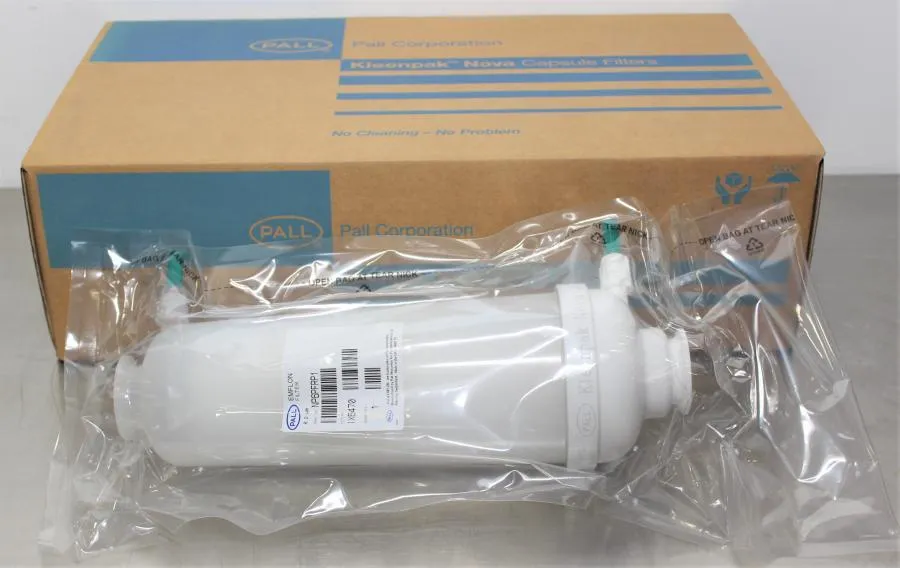

Cleanliness, integrity and simplicity Highlights:

- State-of-the-art designs and materials

- Manufactured on automated equipment under ISO Class 5 (class 100) cleanroom conditions

- Suitable for virtually any storage application

- Standard and custom configurations available

- Integrity tested using Pall Life Sciences advanced whole-bag testing technology

- “Universal” Allegro TK8 biocontainer film

Overview:

Efficient movement and storage of liquids is critical to modern biotechnology processes. The deployment of single-use containers for this task has become ubiquitous in recent years because they reduce risk while also driving down costs in comparison with traditional stainless steel equipment.

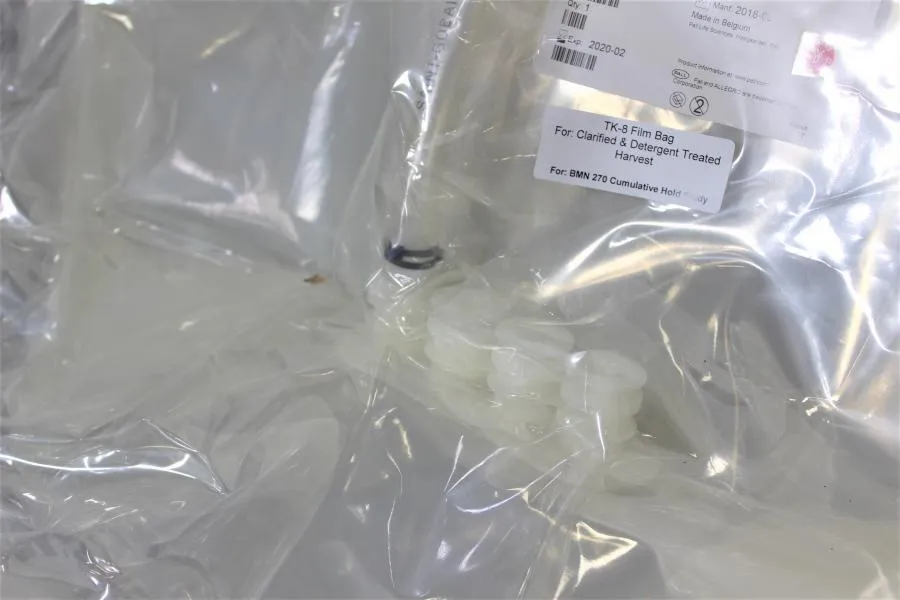

Pall Life Sciences Allegro TK8 products have been developed to meet the demand for cost-effective, scalable single-use liquid storage containers that are compatible with Pall Life Sciences market-leading range of single-use mixing and bioreactor technologies.

At the heart of Allegro TK8 systems and products is the Allegro TK8 film, a state-of-the-art multi-layer gas-barrier polymer laminate. The product-contacting layer of the Allegro TK8 film is blow-extruded in-house by Pall Life Sciences under cleanroom conditions using medical-grade ultralow-density polyethylene resin, then laminated to create a gas barrier film of exceptional cleanliness, strength and clarity that is animal-derived component free (ADCF) and complies fully with USP Class VI requirements.

The Allegro TK8 film is constructed from laminated layers of PA (polyamide), EVOH (ethylene vinyl alcohol polymer) and ULDPE (ultralow density polyethylene). The outer PA layer provides robust puncture resistance, strength, and excellent thermal stability. The EVOH layer minimizes gas diffusion across the film while maintaining a very good flex crack resistance. The ULDPE layers provide flexibility, integrity and an ultra-clean, ultra-pure, low-extractables product contacting layer. The combination of these layers results in a film that has outstanding optical clarity, is easy to handle, and performs well in a broad range of bioprocess applications. The inner ULDPE layer used in TK8 is blow-extruded in-house by Pall under cleanroom conditions (0.2 μm filtered air), ensuring the cleanest possible product contacting surface. Lamination is also performed under controlled, ultra-clean conditions. Lastly, the Allegro TK8 film is converted into Pall biocontainer products in our ISO Class 5 cleanroom.

Traceability and Compliance:

All of the layers in Allegro TK8 film are made from "medical grade" materials, meaning that they comply with industry standards and are subject to strict change controls. The entire structure of the Allegro TK8 film is totally free of any animal-derived components (ADCF). Pall has also created Allegro TK8 film with dual sourcing and contingency planning in mind, to ensure the security of supply.

- Allegro TK8 film complies with USP Class VI (USP<87>, USP<88>, and USP<661>)

- ULDPE resin complies with European Pharmacopoeia (EP) 3.1.3

- Shelf life is supported by validation studies on aging

- Certified ADCF

- Bioburden evaluation available (ISO 11737)

- Particle count data available (EP 2.9.19 or USP<788>)

- By performing blow extrusion in-house, Pall maintains full control and traceability of the contact film composition, from resin through to finished bag product.

Specifications:

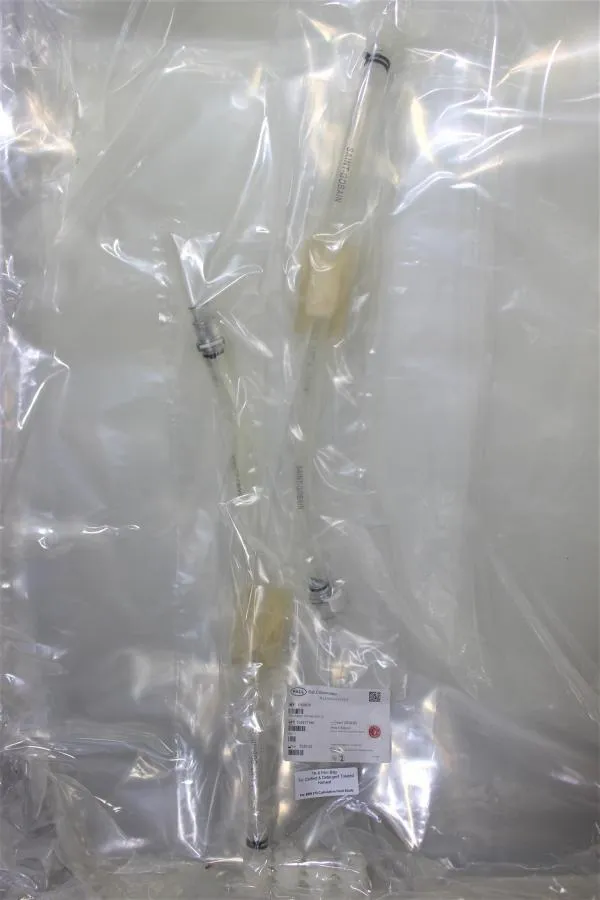

- Bag body dims: 720 mm (W) x 614 mm (H) x 520 mm (D)

- Top-Mounted fill tubing: 500 mm x 1⁄2 in. ID C-Flex TPE

- Bottom-Mounted Drain Tubing: 500 mm x 1⁄2 in. ID

C-Flex TPE - Connectors: CPC MPX M

- Container: 200 L Cubical "Q-Mix"

| Metric | Specification |

| Capacity Overage | 5% |

| Port Locations | Face ported. Top mounted single- or multipleport fitments for fill lines. Bottom mounted single-port fitment for drain. Dip tubes or Easy Drain available upon request. |

| Tubing | C-Flex TPE standard. Platinum cured silicone optional. |

| Connectors | Luer connectors and CPC MPX connectors as standard, others available upon request. |

| Film | TK8 |

| Compliances | All materials and final assemblies meet USP Class VI requirements (USP<87>, USP<88>, USP<661>), USP<788> (particulates), EP 2.9.19 (particulates), ISO 11737 (bioburden). Full extractables/leachables data package available upon request. All contact materials certified Animal Derived Component Free (ADCF). |

| Sterilization Method | Gamma irradiation, 25 - 50 KGy. |

| Shelf Life | 24 months after gamma irradiation. |

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”