PALL Palltronic Flowstar IV FFS04R

- Make Pall

- Hertz 50Hz/60Hz

- Model Palltronic Flowstar IV

- Serial 19359244

- Weight 29

- Voltage 120V/220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 21×26×15 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

- Manufacturing Date 2017

PALL Palltronic Flowstar IV FFS04R

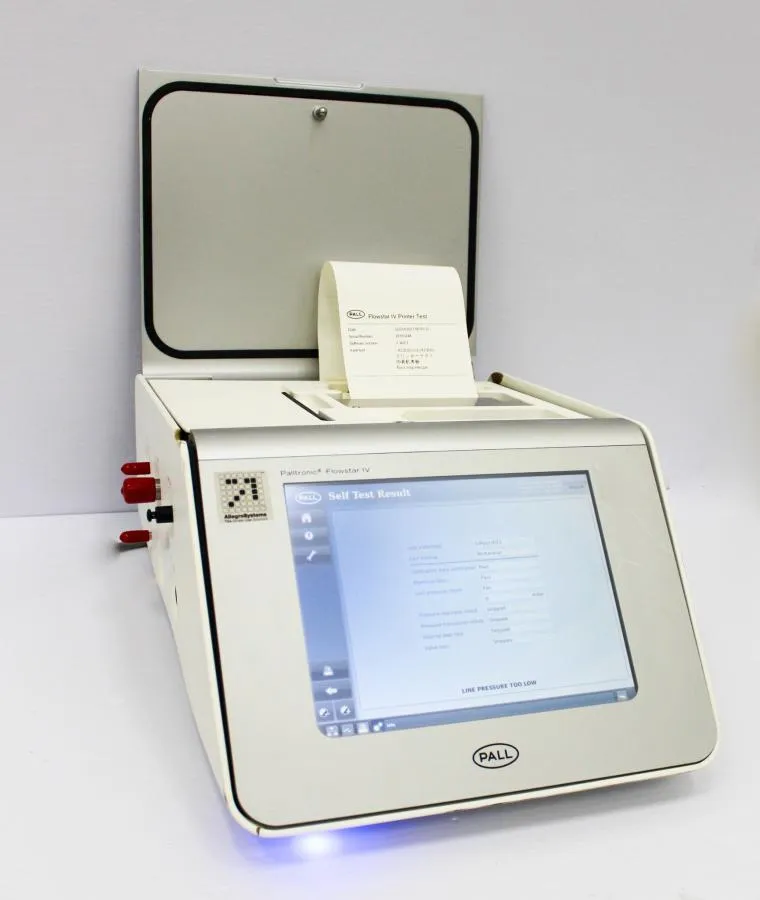

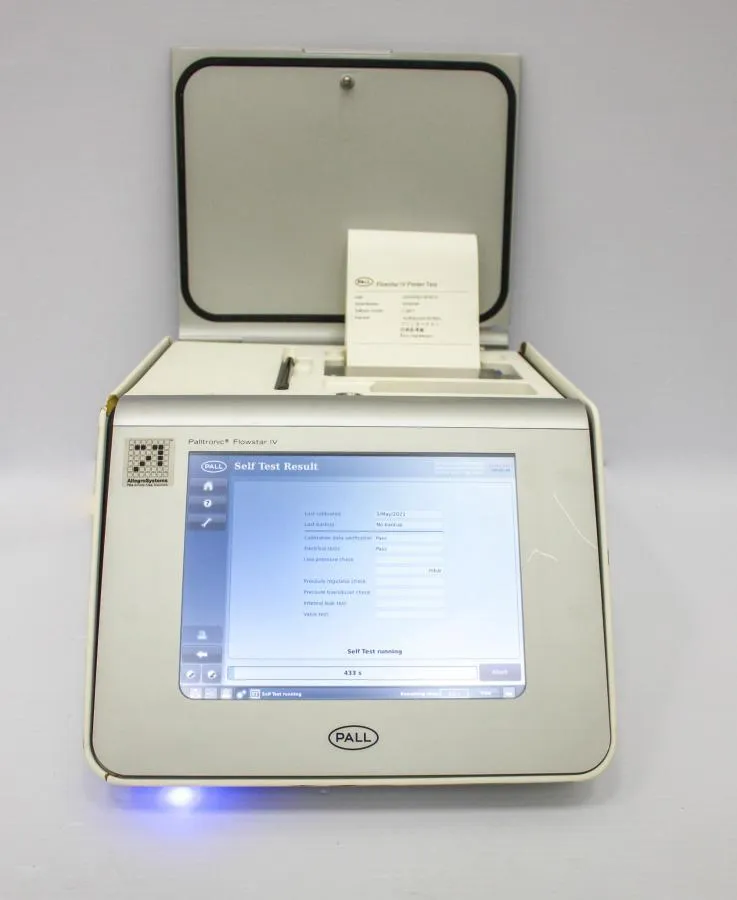

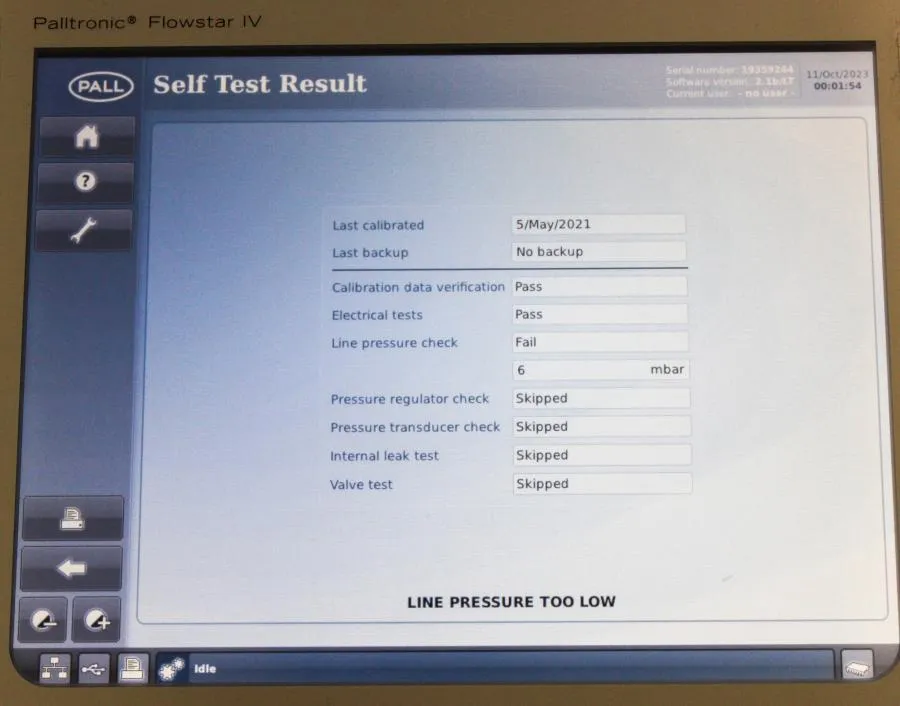

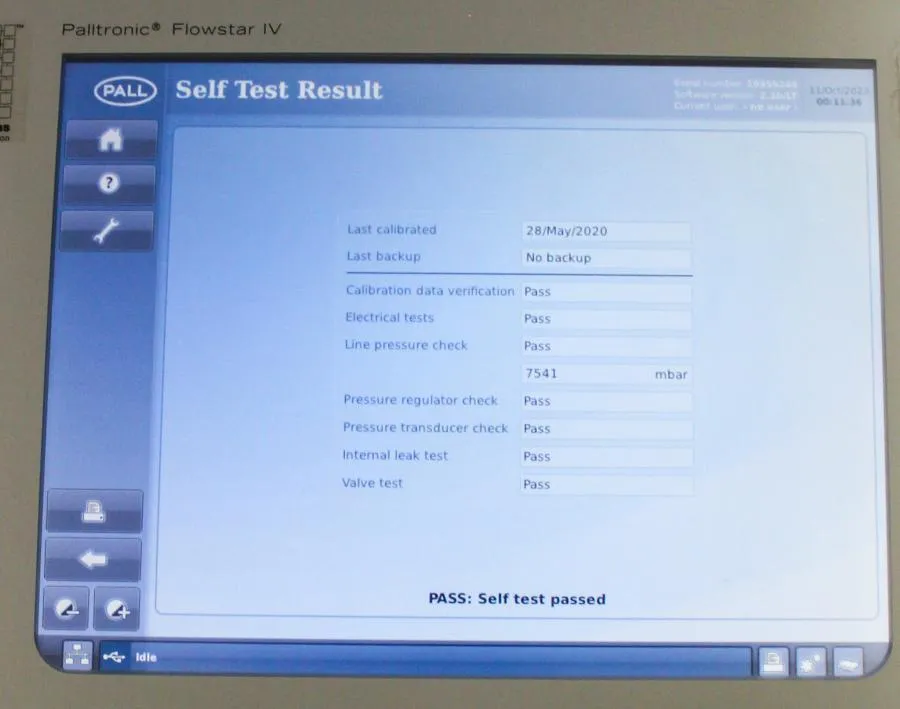

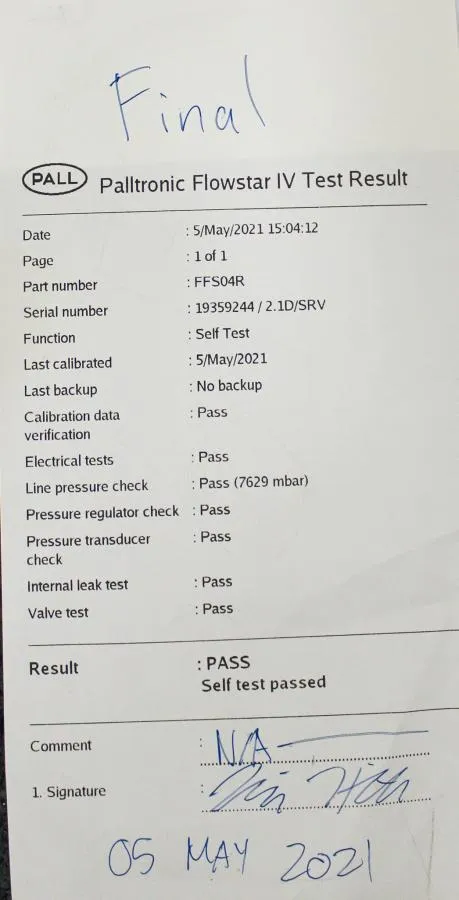

**This unit has been tested to specifications. Has broken right and left corners(Dos not affect functionality) See photos for further details.

- Test filters in a reliable and repeatable way

- Faster integrity testing

- That the Diffusive Flow and Intrusion tests are carried out at a constant pressure

- Electronic data management and remote control

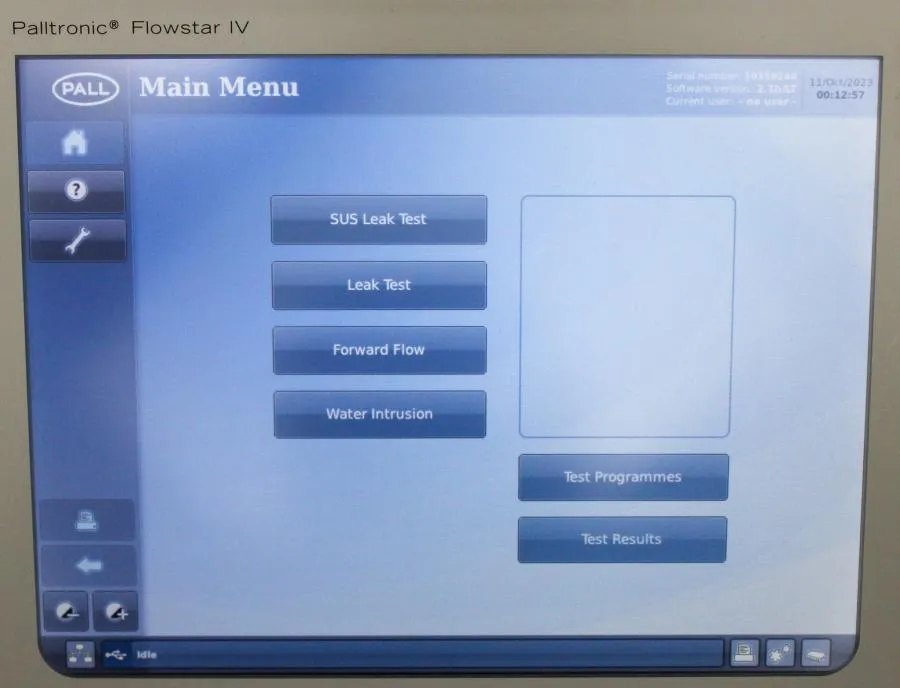

This instrument provides the ability to perform either a Forward Flow Test, Bubble Point Test,

combined Forward Flow and Bubble Point Test, Water Intrusion Test or Leak Test. The filter can

be tested in place or off-line and its performance capacity remains unaffected by the test when

suitable protocols are followed. The instrument provides direct flow measurement of the filter under test. This measurement is independent of upstream volume over a wide range. Extensive internal Self Test features and use of high precision components virtually eliminate the possibility of significant measurement errors. The instrument is connected upstream of the filter under test. The measurements are, therefore, non-invasive of the downstream side of the filter and risk of contamination is eliminated. This is particularly important in installations where the filter has been sterilized before integrity testing.

The test instrument is a small and lightweight portable unit, which has been specifically

designed for ease of use and accuracy of measurement. Data input is carried out using a

touch screen that also displays other essential information. The instrument measures flow and

pressure in real time and displays them graphically on the touch screen. An automatic control

of the test system enables reduced test times to be achieved under stable test conditions.

Test times are automatically extended when unstable conditions are present. An integral printer

provides a permanent record of the test parameters and results. In addition, up to 10,000 test

results can be stored electronically in the instrument’s memory. The test instrument is dustproof and splash proof to a rating of IP54, providing protection against severe laboratory and production conditions. The venting system includes an External Vent Valve to prevent test liquid from migrating into the instrument on completion of the filter integrity test

Specifcications

- Forward Flow Test (FF)

- Bubble Point Test (BP)

- Combined Forward Flow and Bubble Point Test (FF/BP)

- Water Intrusion Test (WIT)

- Leak Test (LT)

- Pressure Decay Test (PD)

- Printout via internal printer

- Storage of test results

- Time and date display

- Automatic Self Test. Automatic control of stabilization and test times

- Language options: English, French, Italian, Spanish and German, other languages in preparation at time of printing

- Units of pressure in mbar, psi, kPa or kp/cm2

- External vent valve

- Password-protected storage of at least 500 test programs

- Self Test: At least 3000 mbar (43.5 psi)

- Flow limit: < 150 mL/min At least 1000 mbar (14.5 psi) above test pressure

- Flow Limit: > 150 mL/min At least 2000 mbar (29 psi) above test pressure

- Test Program Strorage: > 500 programs

- Test Result Storage: > 10,000 tests

- Active User Storage: > 250 users

- Language Options: US English, English, French, German, Italian, Spanish

- Communication Ports: USB ports RS232 port Ethernet port (RJ45) Wireless Ethernet

- Measuring Range Forward Flow Test: 0.1 – 1000 mL/min

Water Intrusion Test: 0.02 – 50 mL/min water

Bubble Point Test: 400 – 6500 mbar (0.725 – 94.2 psi) - Accuracy Forward Flow Test: ± 3% of measurement or ± 0.05 mL/min, whichever is greater Water Intrusion test: ± 3% of measurement or ± 0.02 mL/min, whichever is greater

- Resolution Forward Flow Test: 0.1 mL/min (0.01 mL/min for a flow < 10 mL/min)

Water Intrusion Test: 0.01 mL/min/ Bubble Point Test: 50 mbar (0.7 psi) - Calibration Limits Flow Measurement: ± 3% of measurement

Pressure Measurement: ± 0.33% of full scale - Voltage: automatically adjusted between 100 – 240 V AC, Input Frequency: 50Hz/60Hz

Power: Typically 75 W, peak 150 W, Fuse: 3.15 A, slow blow., External Vent Valve: 24 V DC

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”