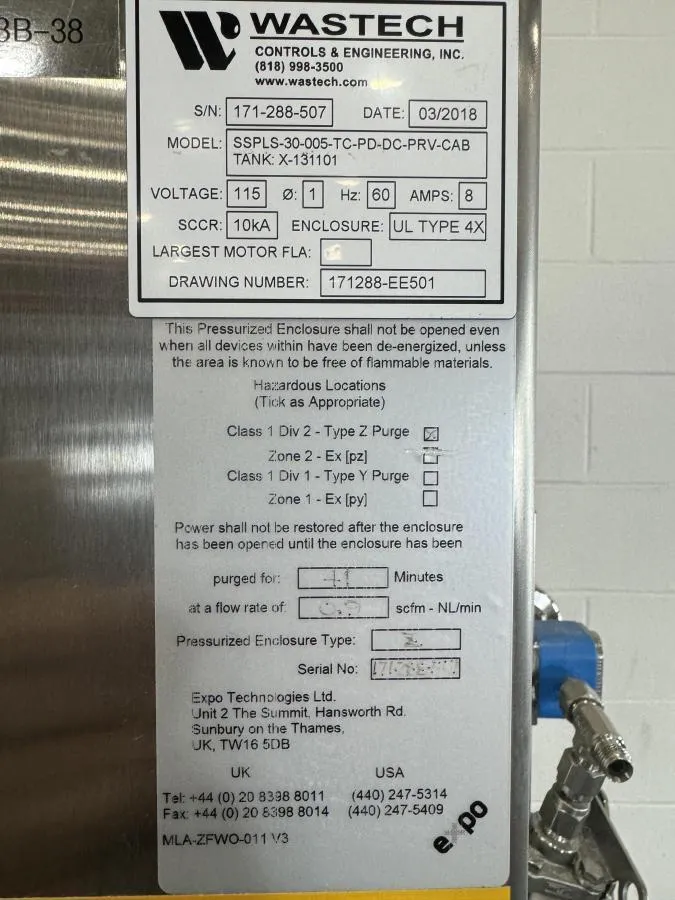

WasTeck Engineering - Solvent Collector SSPLS-30-005

- Make Tech Engineering

- Model SSPLS-30-005

- Serial 171-288-507

- Weight 1875

- Voltage 120V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 56×56×56 in

- Shipping Type Freight

- Item Condition Pre-owned

- Manufacturing Date 2018

WasTeck Engineering - Solvent Collector SSPLS-30-005

**Preowned in very good condition. Buyer can expect a working system, comes with a 30 day warranty. See pictures for details. FOB: Franklin, MA

WasTeck Engineering Lab Waist SSPLS-30-005. Wastech standard stainless solvent pump lift stations are designed to safely and efficiently transfer solvents and other flammables when a gravity drain is not possible. Lift stations use one or two stainless steel pumps and are controlled by Wastech industrial AOD pump control panels (IAPCP). Custom configurations are available, call or email Sales for more information. Solvents are hazardous and difficult to handle. Because of their volatile nature, solvents pose a high fire hazard and must be handled as an explosion risk. Usually a Class 1, Div 1 or Div 2 explosion proof rating is needed. In addition, double containment is typically required due to contamination risks. Solvent dispense systems are offered in single or dual drum configurations. Two solvent drums with automatic change-over capabilities provide time for drum changeout without interruption to the dispense process. The interchangeable drums are installed in a fire-rated enclosure, fully contained, with leak detection and monitoring sensors. Each system is fully monitored and can offer various communication options. Central or local control panels are available using PLC controls.

- SSPLS: simplex solvent pump lift station. Tank Volume: 30 gallons fabricated stainless steel tank with pump size: 1/2'' connection.

- Pump size: 1/2''

- Tank size: 30gl

- Simplex (one pump) or duplex (two pumps) configuration

- Lift station rated for Class 1 Division 1 hazardous environments

- Lift station rated for transfer and storage of Group D solvents

- Corrosion resistant 316 stainless steel tank

- Corrosion resistant 316 stainless steel piping and valves

- Intrinsically safe multipoint level switch assembly

- All pump lift stations include a high-high level switch to activate a high level alarm.

- Lift stations require Wastech industrial IAPCP control panels (or equivalent)

- Heavy duty, reinforced 18-gauge all-welded double wall construction

- 304 stainless steel cabinet

- 3-point self-latching doors with non-sparking latch

- Internal double containment with leak switch

- Tie downs and adjustable leveling legs

- 316 stainless steel valves and piping

- Air operated valves for drum dispense control

- Fire sprinkler

- Low exhaust pressure switch

- Low CDA pressure switch

- Intrinsically safe level switch assemblies

- Proximity switches to confirm proper drum placement

- Stainless steel rollers to facilitate drum installation and removal

- Electrical grounding for cabinet and drums

- Electrical quick disconnects to remove level switches

- Drum valve quick disconnect system for safe and easy drum

- installation and connections

- Standard control panel is remote-mounted and rated for nonhazardous

- locations

- Alarm integration to Building Management System

Standard Features

- Fabricated 316 stainless steel tank (5, 15, 30, 60, and 100 gallon tanks standard, custom sizes available)

- 316 Stainless steel lid

- 316 stainless steel piping and valves

- One or two pumps—Air operated 316 stainless steel ATEX-rated double-diaphragm style (Teflon Diaphragm)

- 2” FNPT top mount inlet connection (1” for 5 gallon tank)

- 2” FNPT top mount vent connection (1” for 5 gallon tank)

- Hatch for maintenance access

- 316 Stainless steel intrinsically safe multipoint float level switch assembly

- Seismic tie-downs

- Grounding lug Optional

- Fabricated 316 stainless steel double containment tank with float leak switch

- Side inlet connection

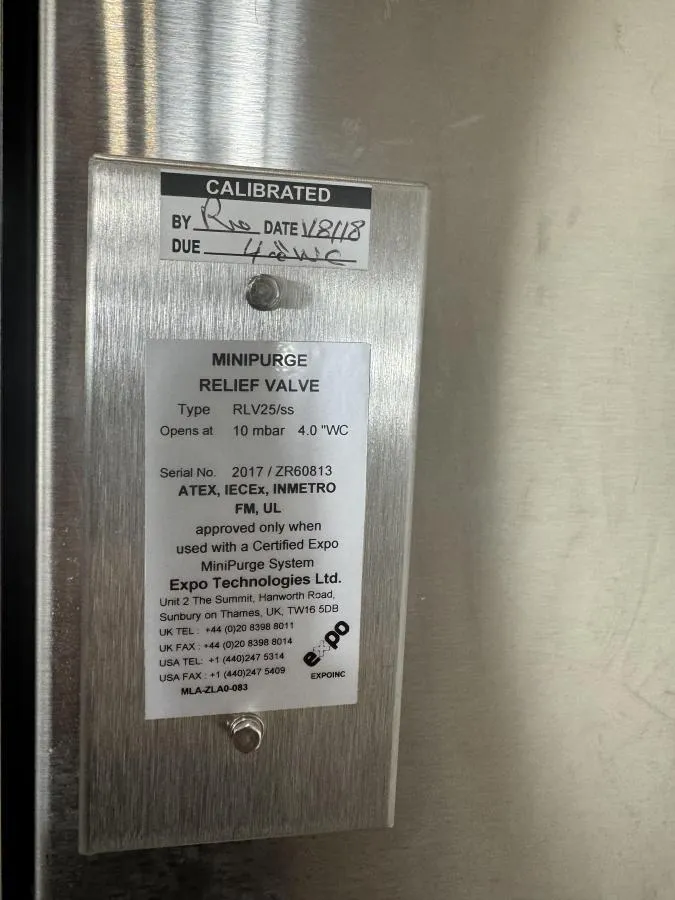

- Pressure relief valve downstream of the pumps to prevent system piping overpressure

- Pulsation dampener with Teflon Diaphragm on discharge line (simplex) or on common discharge line (duplex)

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”