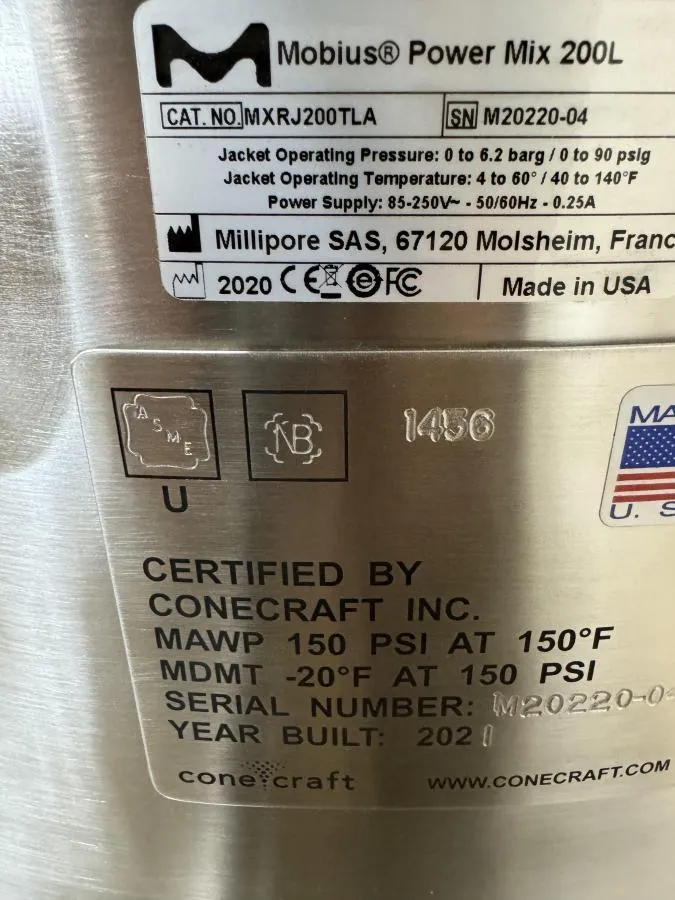

Millepore Mobius 200 Liter Single Use Mixing System, Jacketed Stainless

- Make Millepore

- Hertz 50Hz/60Hz

- Model Mobius Power Mix 200L

- Serial M20220-04

- Weight 250

- Voltage 120V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 45×45×75 in

- Shipping Type Freight

- Item Condition Pre-owned

Millipore Mobius 200 Liter Single Use Mixing System, Jacketed Stainless

**this unit is preowned and in very good condition. Buyer can expect a working system that comes with a 30 day warranty. See pictures for details. FOB: Franklin, MA

Mobius® Power MIX 200 is a 200 liter high performance,

single-use mixing system targeted for small scale

mixing in biopharmaceutical product/process

development and manufacturing. Leveraging the

proven technology of magnetically coupled NovAseptic®

mixers, traditionally used with stainless steel tanks,

the Mobius® Power MIX platform offers solutions for

a wide range of mixing applications, including high

concentration buffers and hard-to-mix cell culture

media. This application note presents performance data

from the Mobius® Power MIX 200 for mixing of these

sinking and floating powders. A characterization map of

liquid-liquid mixing for a range of volumes and speeds

is also included.

Figure 1. Power MIX 200 stainless steel and plastic carriers

Mixing Type Final Product Mixing Time

Liquid-Liquid NaCl solution 25 seconds

Sinking Powder, low concentration 1X DPBS Buffer 2 minutes

Sinking Powder, high concentration 1.5M NaCl 9 minutes

Floating Powder, basal medium DMEM 7 minutes

Floating Powder, chemically defined medium MilliporeSigma Ex-Cell® Advanced™ Medium 14 minutes

Floating Powder, chemically defined medium Custom MilliporeSigma CHO Medium 30 minutes

Introduction

Mixing of buffers (sinking powders) and media (floating

powders), presents substantial challenges in getting

good dispersion and dissolution of particles. The

creation of a vortex and abundant surface movement

in the Mobius® Power MIX 200 is key to the success

in these processes. The axial and radial flow patterns

allow for quick distribution of sinking powders,

minimizing settling at the bottom of the vessel.

Floating powders are drawn into the vortex, allowing

for effective wetting and distribution throughout the

entire vessel volume. With impeller speed up to 380

rpm, complete mixing for even the most difficult

powders can be achieved in less than 30 minutes.

Quantification of mixing time is traditionally

accomplished by tracing the response of pH and/

or conductivity, along with visual observations of

powder dissolution. In these trials, conductivity and

pH sensors are in two locations within the vessel; in

the probe port at minimum volume and at surface

of the liquid. Video records of the mixing process

provides the visual data. In addition to conductivity

and pH measurements, an FBRM® (Focused Beam

Reflectance Measurement) probe is used to track the

distribution of particles over time. The FBRM® probe

from Mettler Toledo® uses a focused laser beam directly

into the process, determining the backscatter of light

to measure and count particles. Analysis of the trace

curves of conductivity and particle distribution to find

stability is used to determine mixing time, matching

this measured response to the visual data

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”