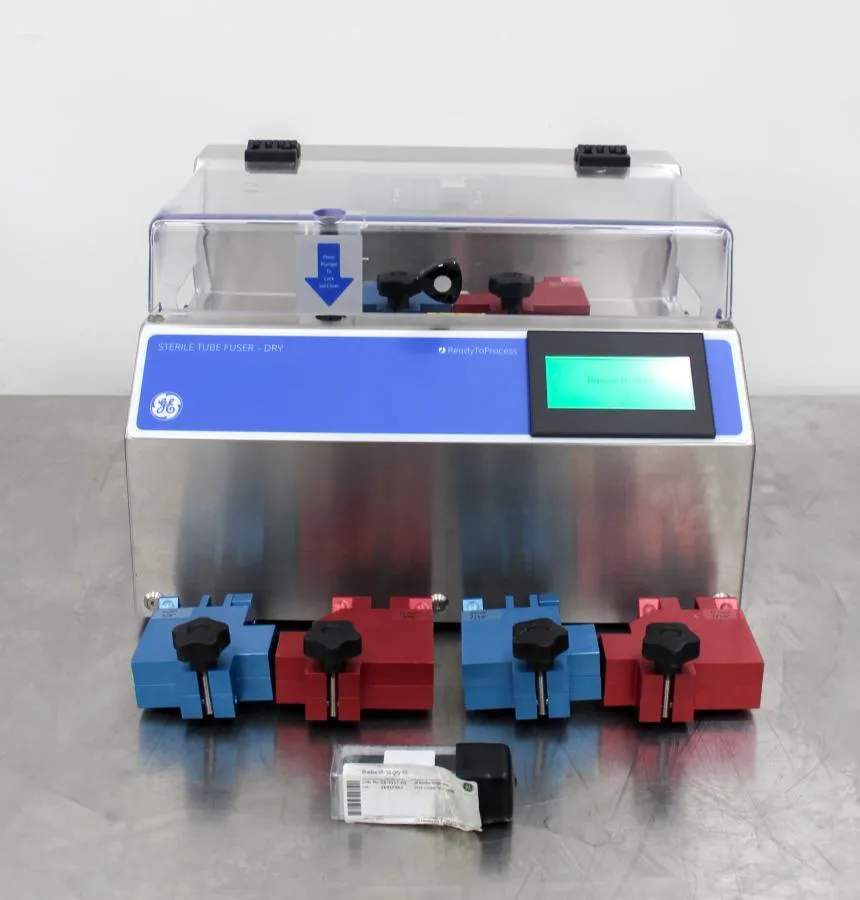

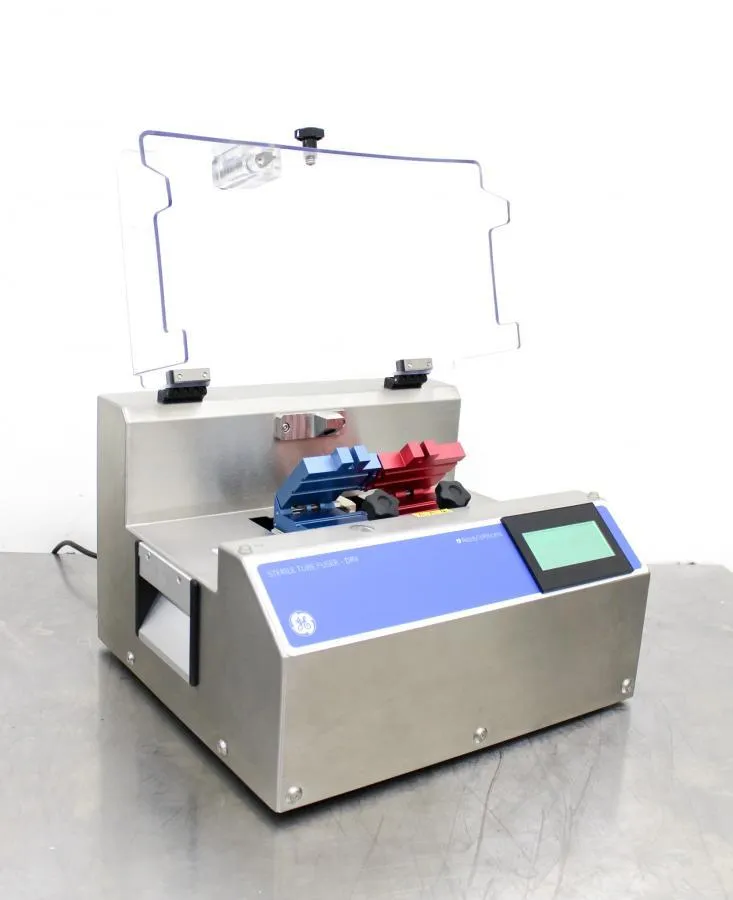

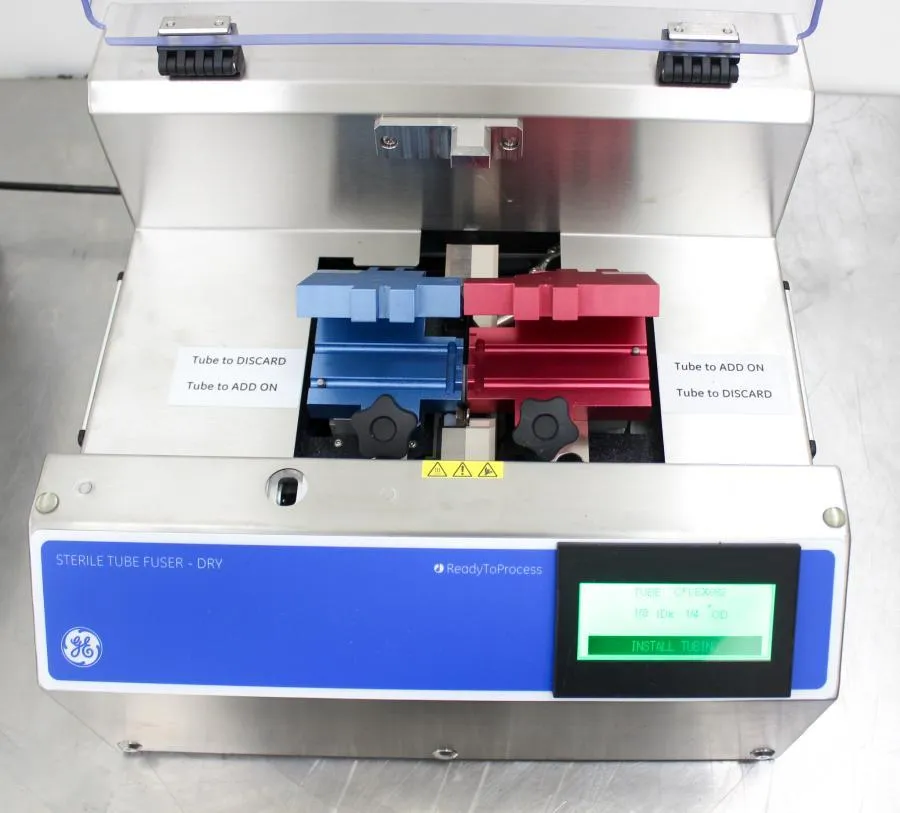

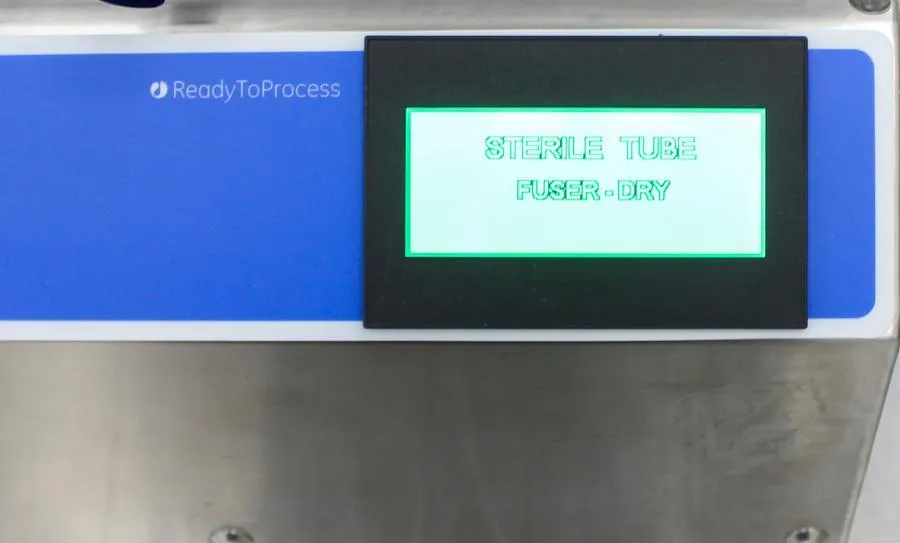

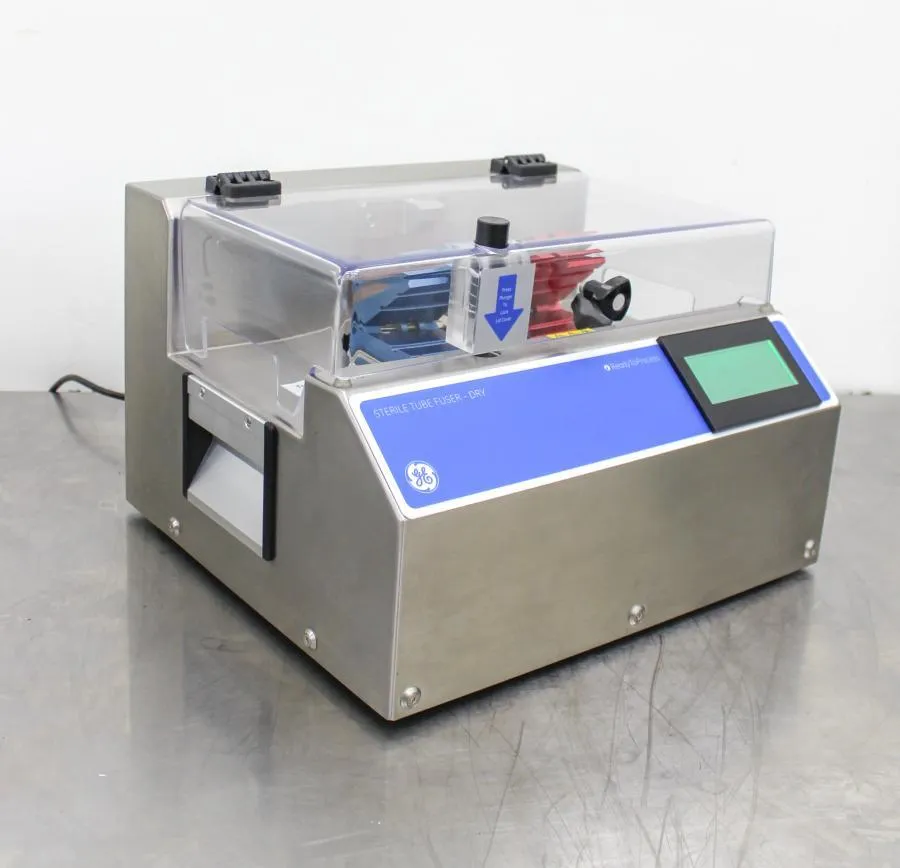

GE/ Cytiva Welding Welder Sterile Tube Fuser-Dry 28999602

- Make GE

- Hertz 50Hz/60Hz

- Model 28999602

- Serial 2173266

- Weight 48

- Voltage 120V/220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 23×21×24 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

- Manufacturing Date 2016/12

GE/ Cytiva Welding Welder Sterile Tube Fuser-Dry 28999602

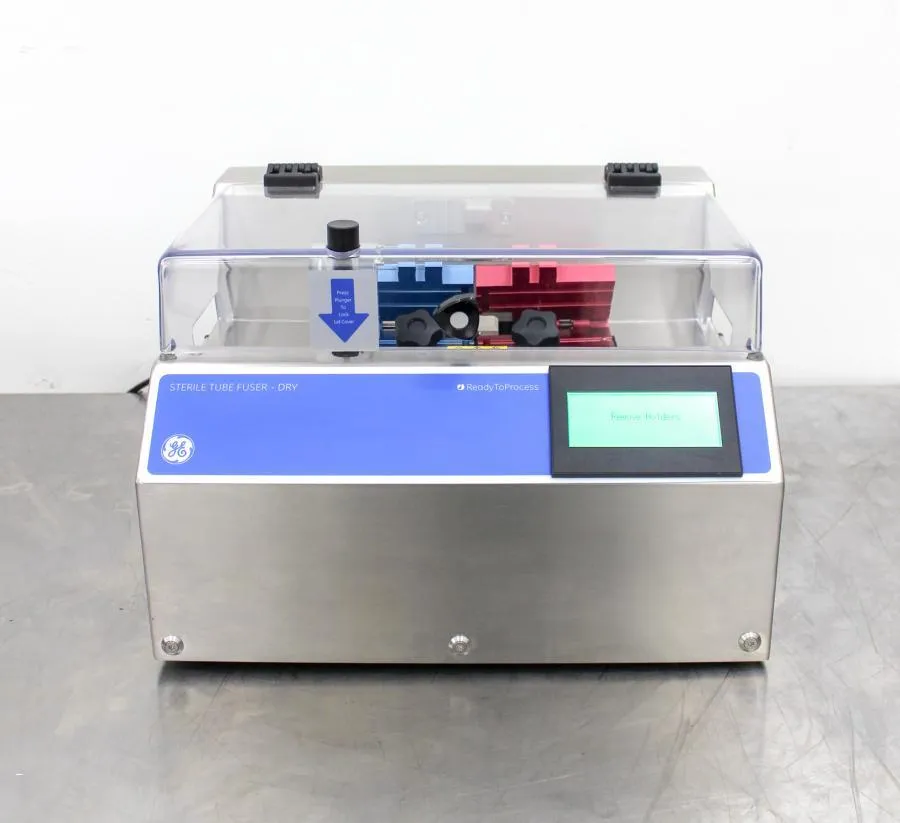

**This Unit has been tested to specifications. Has slight cosmetic blemishes for regular use. Tubbing not include. All in pictures is included. See photos for further details.

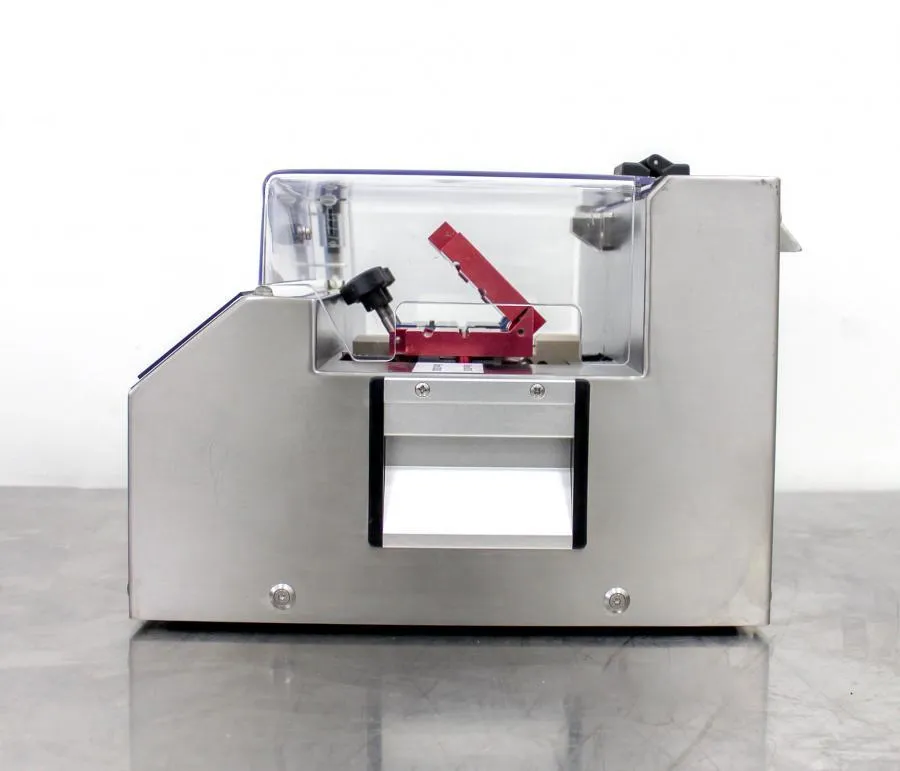

Cytiva, ThermoPlastic welder Sterile Tube Fuser-Dry is an automated device for welding together dry thermoplastic tubing in an aseptic operation without the need for a laminar flow cabinet or similar environmental control device.

- the Sterile Tube Fuser-Wet unit. C-Flex® tubing diameters of 1/4” and 7/16”

o.d. can be welded using interchangeable tubing holders. - The weld forms a small ridge on the inside and outside surface. The inside ridge is typically about a 1 mm high and poses no significant flow restriction (similar to a barbed fitting). If you think the ridge is excessive, it can be reduced, but this may compromise the tensile strength of the welded connection.

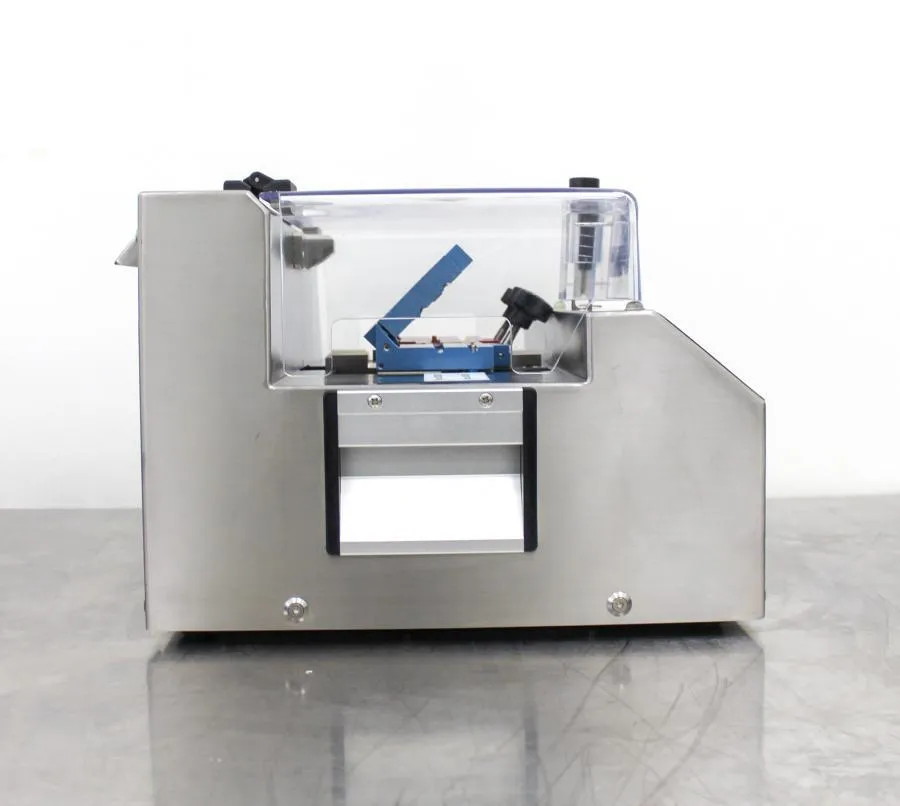

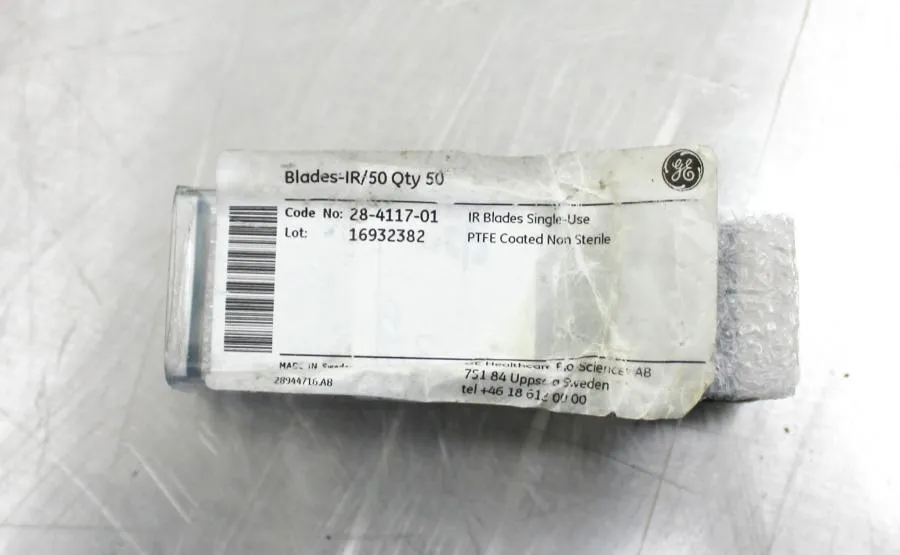

- We do not recommend reusing the blade because of the potential for cross-contamination and compromise of blade construction. The blade gets some tubing residue during operation and this must be cleaned thoroughly if the blade is to be reused.

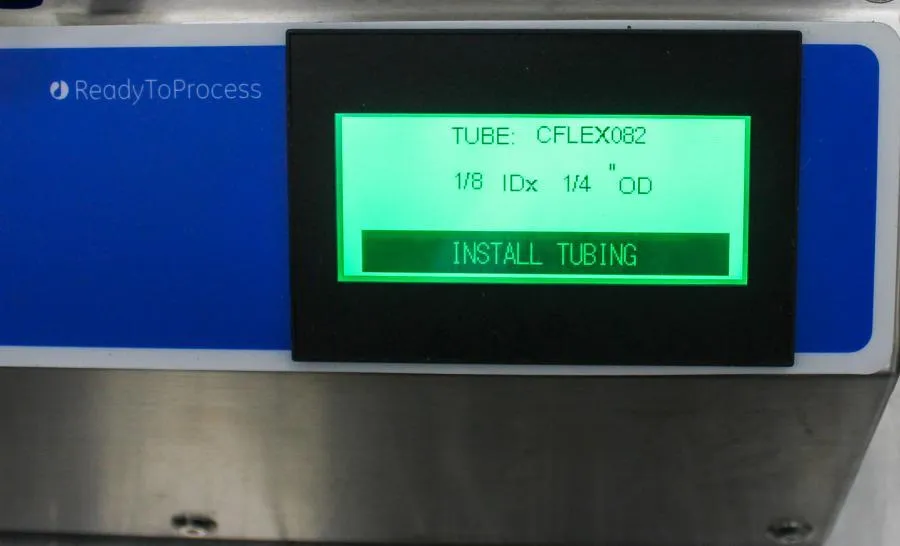

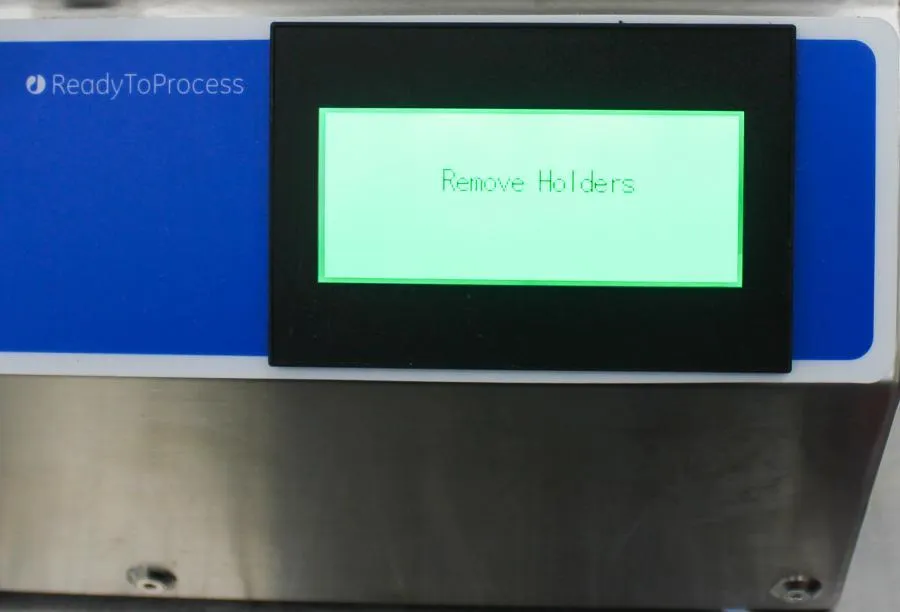

- Tubbing: Check that the tubing is aligned properly. If not, return for service. Make sure you are letting the tubing cool completely before pulling at the weld. It takes 4 to 5 minutes for the full weld strength to develop.

Specifications

- Performance: Tubing diameters from 1/4″ to 7/8″

- Typical Welding Cycle: 2 to 3 minutes

- Non-contact infrared blade temperature sensor

- Uses single-use PTFE coated cutting blades

- Power: 100 to 240 V~ auto switching, 50 or 60 Hz, 3.3 A

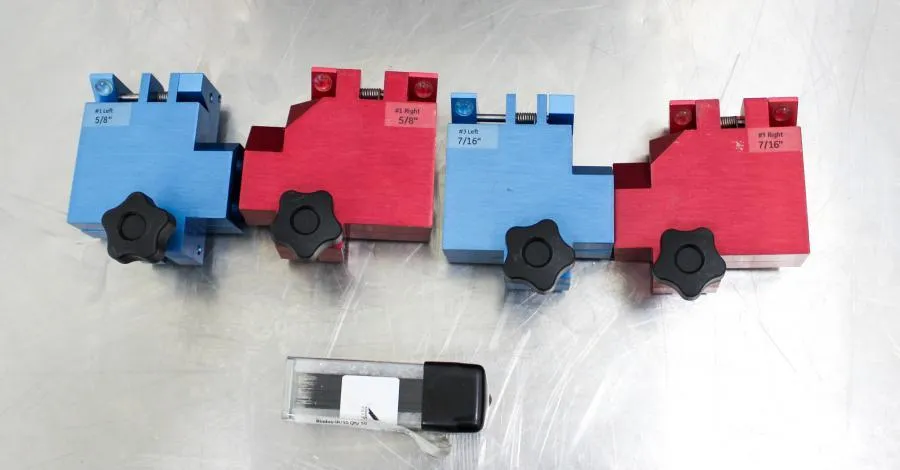

- Tubing Holders Included: Red & Blue – 1/4″– 5/8″ – 7/16″

- Fuse 2 x T4.0 AL 250 V, 5 × 20 mm.

- 1 Pack of Cutting Blades

- Enclosure Indoor use only

- Pollution Degree 2

- EMC FCC Part 15 Subpart B Class A and EN61326-1

- LVD IEC/EN/UL61010-1 and CAN/CSA-C22.2 No. 61010-1

- Relative humidity 20 to 80% non-condensing

- Storage Temperature: -20°C to 60°C

- Operating Temperature: 0°C to 30°C

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”