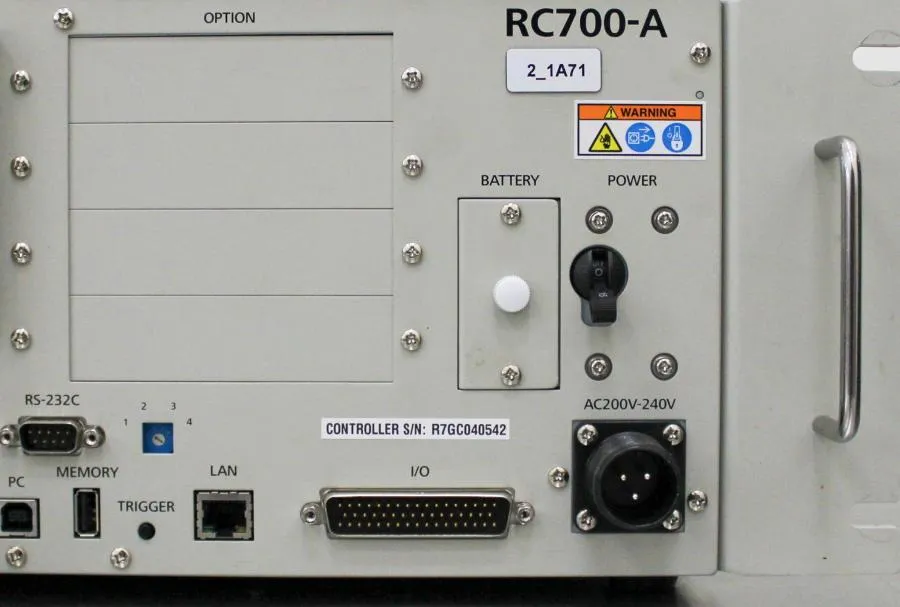

EPSON G3-351S Robot Arm with Controller RC700-A (AS - IS for Parts)

- Make Epson

- Hertz 50Hz/60Hz

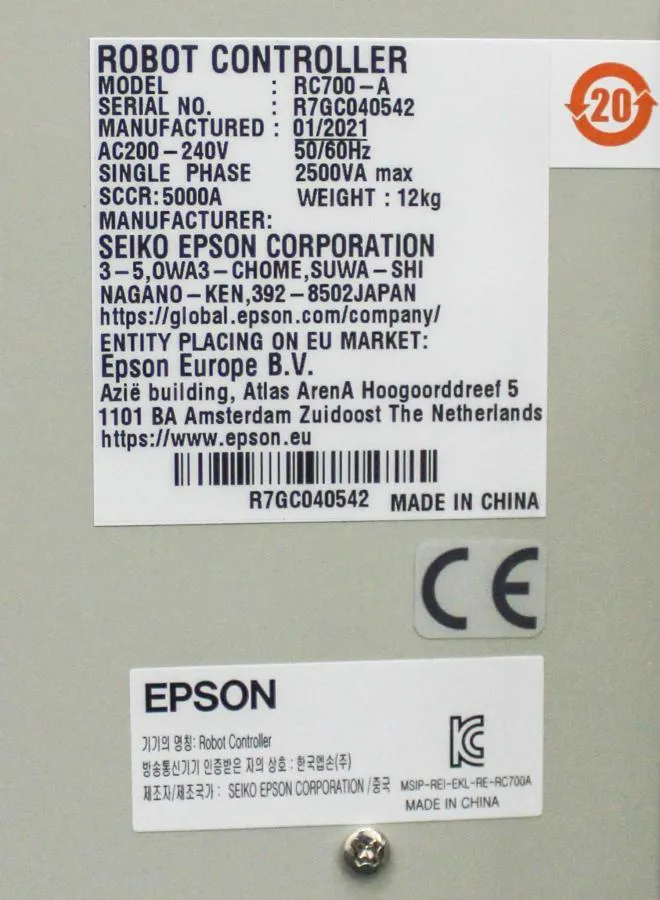

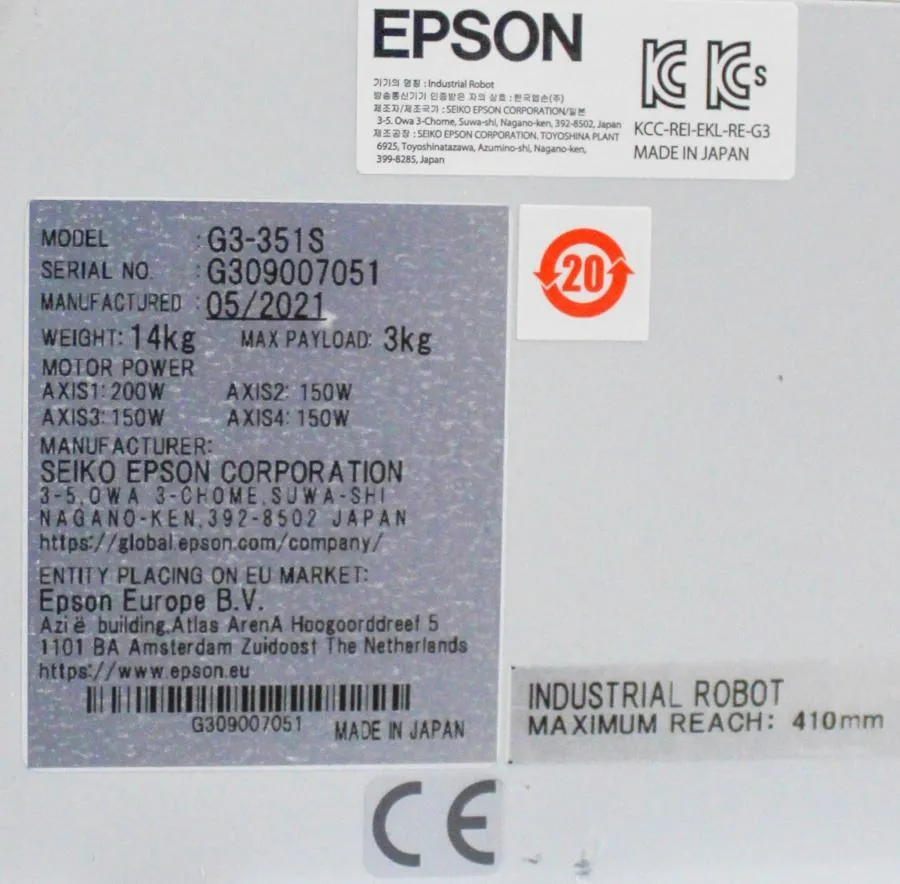

- Model Robot Controller RC700-A/ G3-351S

- Serial G309007051/ R7GC040542

- Weight 90

- Voltage 230V

- Working Working

- Warranty AS-IS

- Dimensions 35×25×21 in

- Shipping Type Freight

- Item Condition Pre-owned

- Manufacturing Date 05/2021/ 01/2021

EPSON G3-351S Scara Robot Arm with Controller RC700-A

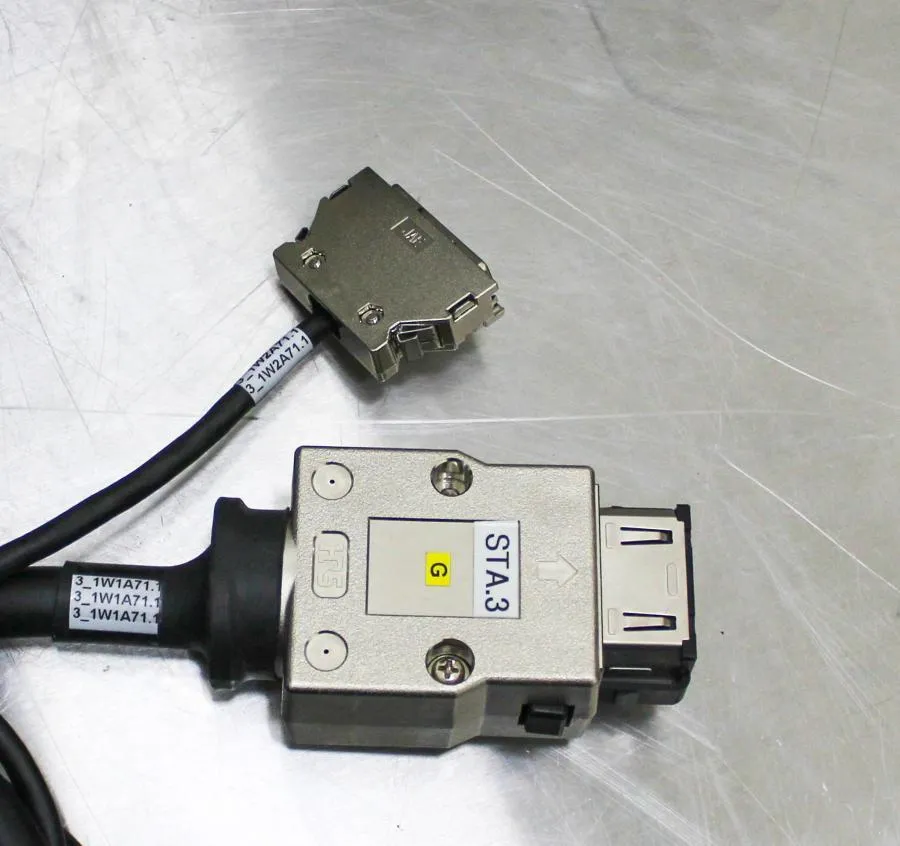

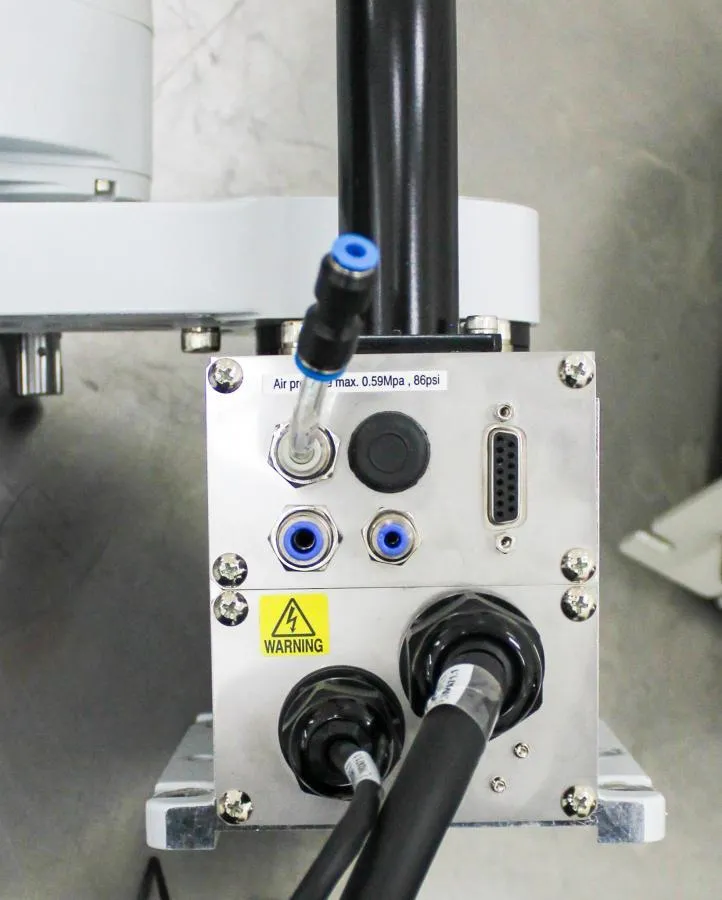

**Industrial robot Power cord Not included and unable for fully test. Missing other components to completely test . Has slight cosmetic blemishes from normal use. See photos for further details.

The RC700A Controller is the next generation high performance EPSON Robot controller with power, open architecture, and industry leading ease of use. The PowerDrive servo system with our new QMEMS servo feedback sensing provides the latest in servo control technology for fast accel/decel times as well as high performance motion profiles and path control not seen with other robots. In addition, the SPEL+ language and Industry Leading EPSON RC+ development environment (new Version 7.0) provide the tools to make robot programming easier to help save our users time and money. With the ability to control up to (3) 6-axis arms, the RC700A has all the power you need yet for the most demanding applications. However, at the same time, the EPSON RC+ development environment is 2nd to none in ease of use.

High Performance

- High Performance AND Open Architecture

- Super fast CPU's and powerful real time performance

- Fast Robot Cycle and Program Execution Times

- Outstanding Accel/Decel Rates with smooth start/stop motion

- Controls up to (3) 6-Axis Arms

- Epson QMEMS with PowerDrive Servo system ensures maximum robot performance

Flexibility and Expandability

- Ability to easily add 3rd party software and Hardware

- User can select and use the PC of their choice for maximum power

- Controls Epson C4/C4L 6-Axis Robots. (more models coming soon)

- Fully Integrated Options including: Vision Guidance, .NET Connectivity (EPSON RC+ 7.0 API), EtherNet/IP, DeviceNet, GUI Builder and more

Best in Class Controllers and Development Software

- Epson RC+ leads the industry in ease of use to save development time

- Two tiered controller offerings allow high performance or low cost solutions

- Integrated options to maximize system performance and reduce overall development time (see options page for more details)

- High performance processing power many times faster than competitors models

Used for a Wide Variety of Applications and Industries

- Automotive

- Hard Drive

- Medical

- Lab Automation

- Consumer Products

- Industrial Products

- Telecommunications

- Pharmaceutical

- Solar

- Packaging

- Semiconductor

- Food

- Electronics

Specifications

- Basic Hardware Specs: Chassis Description: Single Box Chassis; 19 inch rack mount size

CPU: Intel CPU for Maximum Performance. Memory: 1GB. Option Slots: 4 Real Time Option Slots - PC Requirements: Operating System: Microsoft Windows 7 and 8 Professional (On User PC

- Source Code Editor: Color coded with auto syntax assist, code indent, and built-in EPSON Smart Sense Technology

- Communication Interfaces: Ethernet TCP/IP multiple communication channels available from SPEL+

- Development Environment: EPSON RC+ 7.0 - Project based development environment including:

- Project Explorer for easy access to application files

- Point file spreadsheets for editing points

- Run Window for fast development

- Robot Manager for Jogging, teaching points, and configuring robot parameters

- I/O Monitor and I/O Label Editor allow easy setup and viewing of I/O Status

- Task Manager provides debugging/monitoring dialog for all actively running tasks

- Point and click configuration wizards

- Operator Window for easy production use

- Fully Integrated help system

- Digital I/O: Standard I/O: 24 Inputs / 16 Outputs (Optically Isolated)

Expansion I/O: 24 Inputs / 16 Outputs (up to 4 boards max) - Debugger: Source level with single step, breakpoints, watch variables and built in EPSON Smart sense technology

- Teaching Methods: Remote, Direct, Manual Data Input

- Multitasking: Up to 48 simultaneous tasks (16 are background tasks)

- SPEL+ Language: SPEL+ high performance language with 425+ commands

Powerful, easy to learn structured language with features including: functions, parameter passing, variable types, long variable names, event traps, error handling and much more - Languages Supported: English, French, German, Japanese, Chinese

- Environment: Temperature: 5-40 deg C Humidity: 20-80% (no condensation) Standards for Environment: RoHS

Safety Standards and Features:

- CE Compliance

- Emergency stop switch

- Safeguard Circuit

- Low Power Mode

- Dynamic Brake

- Encoder Cable Disconnection Error Detection

- Motor Overload Detection

- Irregular Motor Torque Detection

- Motor Speed Error Detection

- Positioning Overflow

- Speed Overflow

- Servo Error Detection

- CPU Irregularity Detection

- Memory Check-Sum Error Detection

- Motor Driver Overheat Detection

- Over-Voltage Detection

- AC Power Supply Voltage Reduction

- Temperature Error Detection

- Fan Error Detection

Robot Manipulator Control: Joint Control: Up to 6 joints simultaneous control (AC Servo)

Motion Type: CP (Continuous Path) motion, PTP (Point to Point) motion

Speed/Accel/Decel: Fully programmable

Multiple Robot Control: Up to 3 robots (18 axes) from 1 controller

Power Source: 200-240 VAC Single Phase 50/60 Hz

Maximum Power Consumption: 2.5 kVA (depending upon manipulator model)

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”