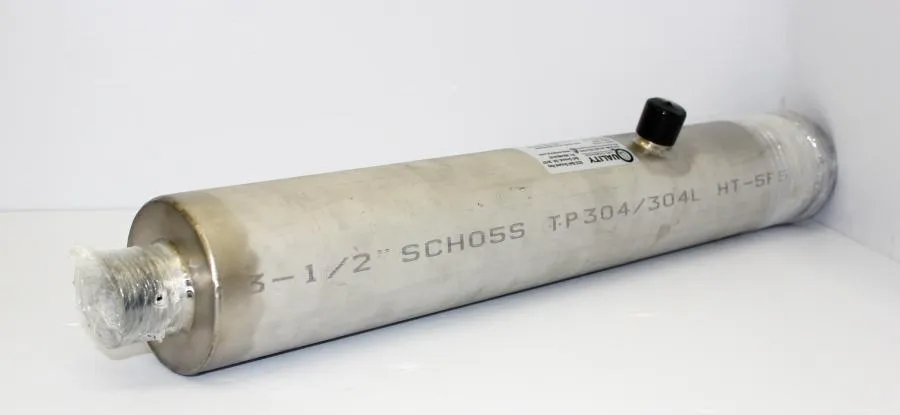

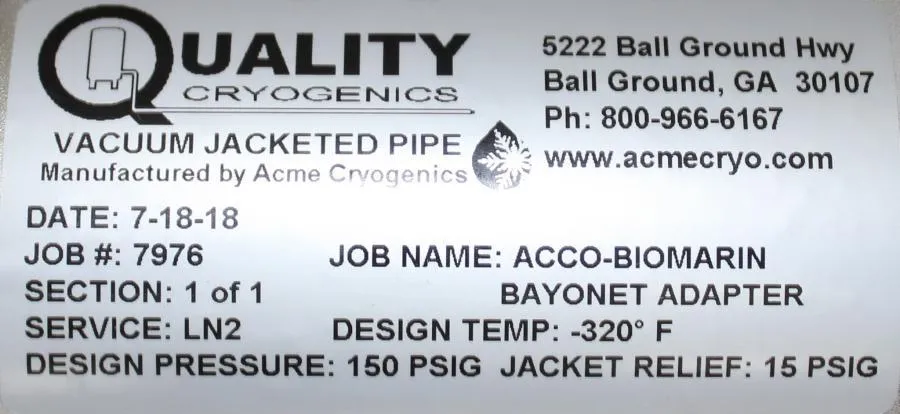

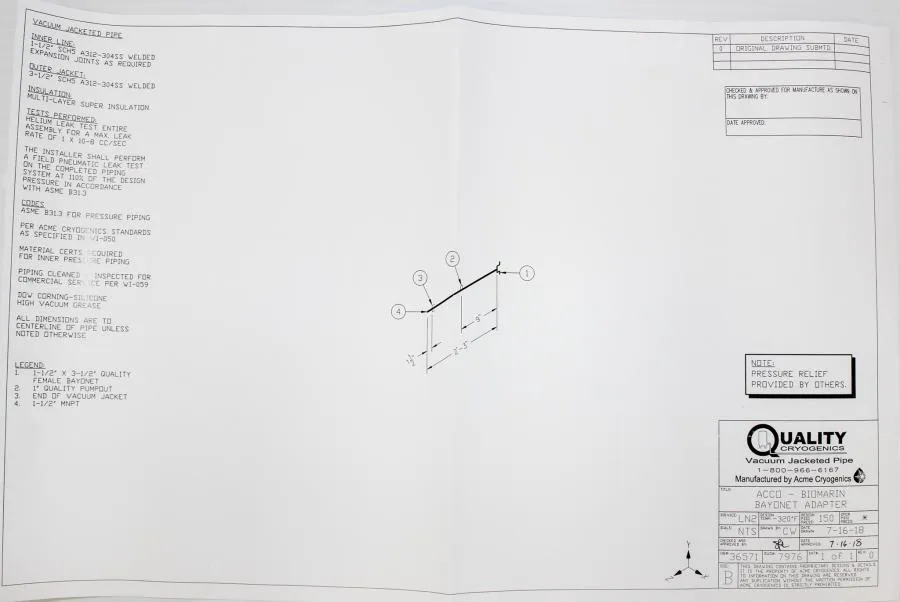

Quality Cryogenics Vacuum Jacketed Pipe Bayonet Adapter

- Make Quality Cryogenics

- Model Bayonet Adapter

- Serial 7976

- Weight 63

- Working Working

- Includes User Manuals

- Warranty 30-Day Warranty, 100% Parts and Labor

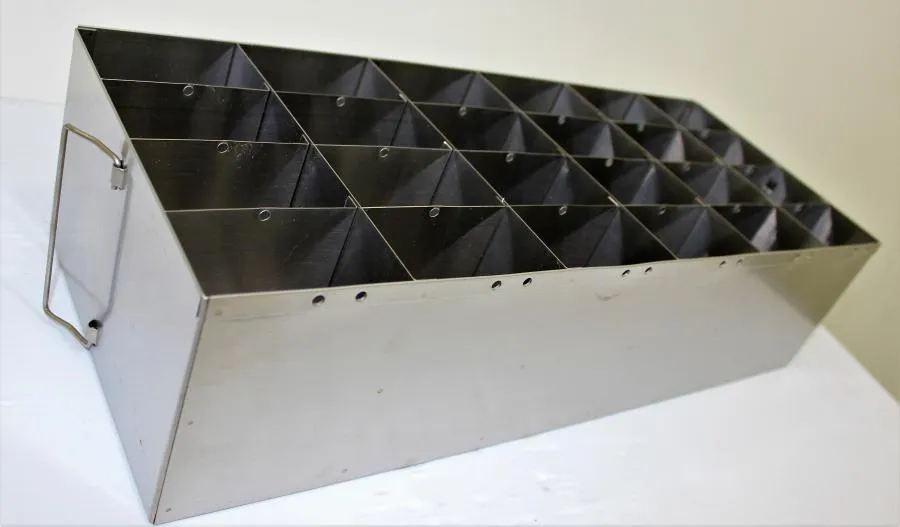

- Dimensions 36×11×14 in

- Shipping Type Freight

- Item Condition New other (see details)

Quality Cryogenics Vacuum Jacketed Pipe Bayonet Adapter

**Unit in Box, ready to use. Single unit in Open box with instructions for installation. See photos for further details.

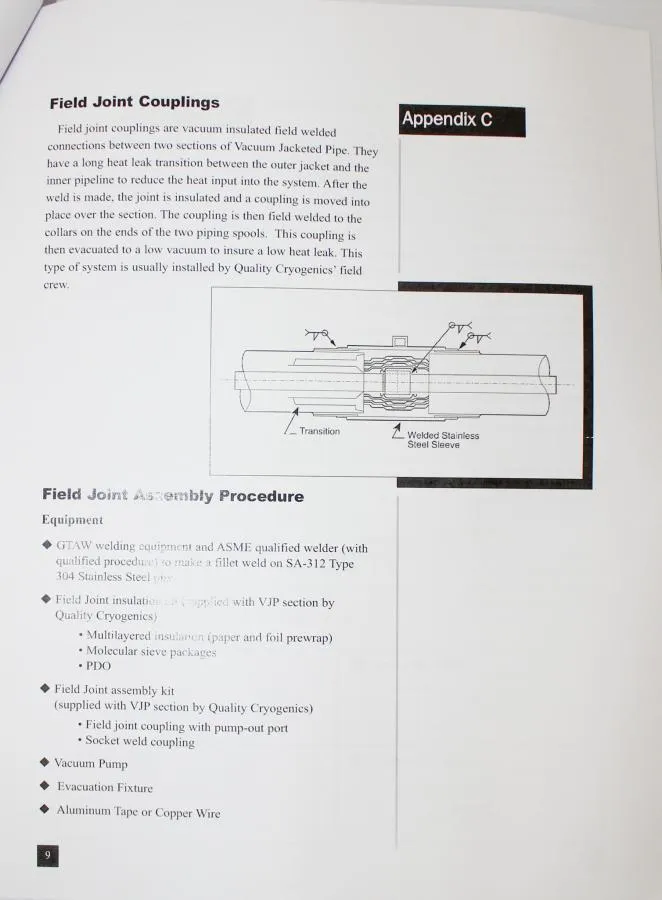

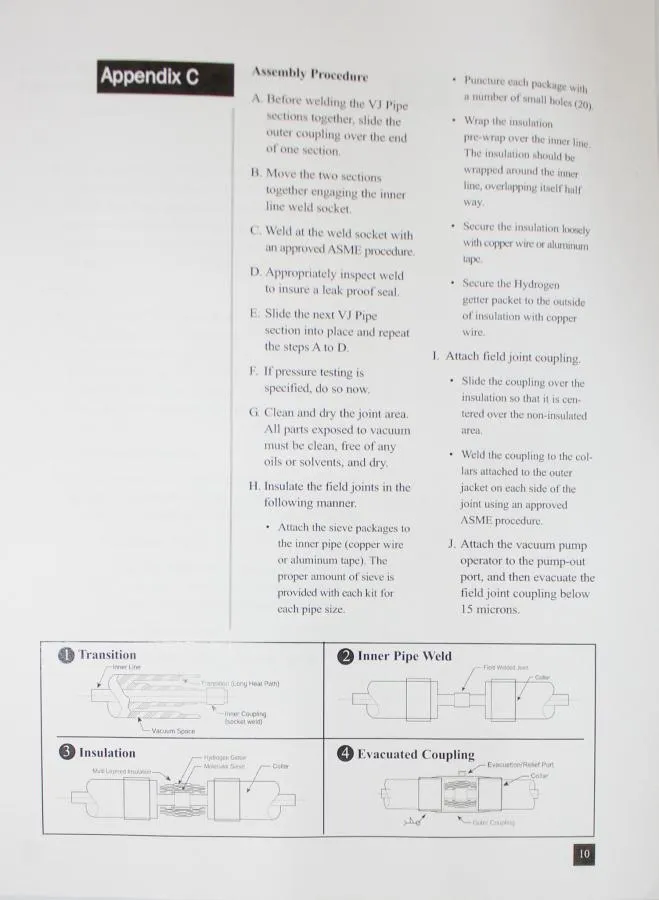

Vacuum Jacketed Pipe is the preferred choice for the safe, reliable, and cost-effective transfer of cryogenic liquids including liquid nitrogen, oxygen, argon, helium, hydrogen and natural gas. The VJP system consists of two 300 series stainless steel pipes: an inner pipe through which the cryogenic liquid flows, and an outer pipe that seals a vacuum space and forms a “vacuum jacket.” Multiple layer insulation (MLI) between the pipes coupled with a low vacuum ensures optimal thermal efficiency. Vacuum Jacketed Pipe efficiently transfers liquids at pressures up to 150 psi or greater. These systems minimize heat leaks to maximize efficiency and savings over time. When an off-the-shelf, one-size-fits-all approach won’t do, you can trust Acme’s Vacuum Jacketed Pipe systems to meet your unique performance requirements.

The Acme Cryogenics team designs manufacture and test our vacuum jacketed piping and components using the highest available standards. All Inner Process and Outer Jacket Welds are Helium mass spectrometers tested at 1 x 10-9 cc/second, sealed at 9 microns or less.

| Features | Related Benefits |

| DOUBLE WALLED CONSTRUCTION |

LOWEST HEAT INLEAK ON THE MARKET

|

| FACTORY SEALED VACUUM SECTIONS |

VACUUM INTEGRITY FOR UP TO 20 YEARS

|

| PREFABRICATION |

EASY SHIPPING AND INSTALLATION

|

| VACUUM INSULATION |

MAXIMUM LIQUID PRESERVATION

|

|

MINIMAL CRYOGENIC LIQUID LOSS

|

LOWER ULTIMATE GAS COSTS

|

|

SERIES 304 STAINLESS STEEL FABRICATIONS

|

MAXIMUM SERVICE LIFE

|

|

BAYONET DESIGN OPTIONS

|

INSTALLATION IS EASY

|

|

STANDARD PIPE HANGERS

|

LOW INSTALL AND MAINTENANCE COST

|

|

MODULAR CONSTRUCTION

|

EASY TO EXPAND AND MODIFY

|

|

INTERNAL LIQUID TRAPS

|

PREVENT BOIL-OFF

|

|

VACUUM JACKETED VALVES

|

BRANCH AND EQUIPMENT ISOLATION

|

|

FLEXIBLE PIPING OPTIONS

|

THERMAL CONTRACTION AND ARE SIMPLE TO INSTALL

|

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”