Repligen XCell C24U v3.0 ATF System Controller

- Make Repligen

- Hertz 50Hz/60Hz

- Model C24U c3.0 ATF System Controller

- Serial 20015352-001

- Weight 28

- Voltage 120V/220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 16×18×21 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

- Manufacturing Date 12/2020

Repligen XCell C24U v3.0 ATF System Controller

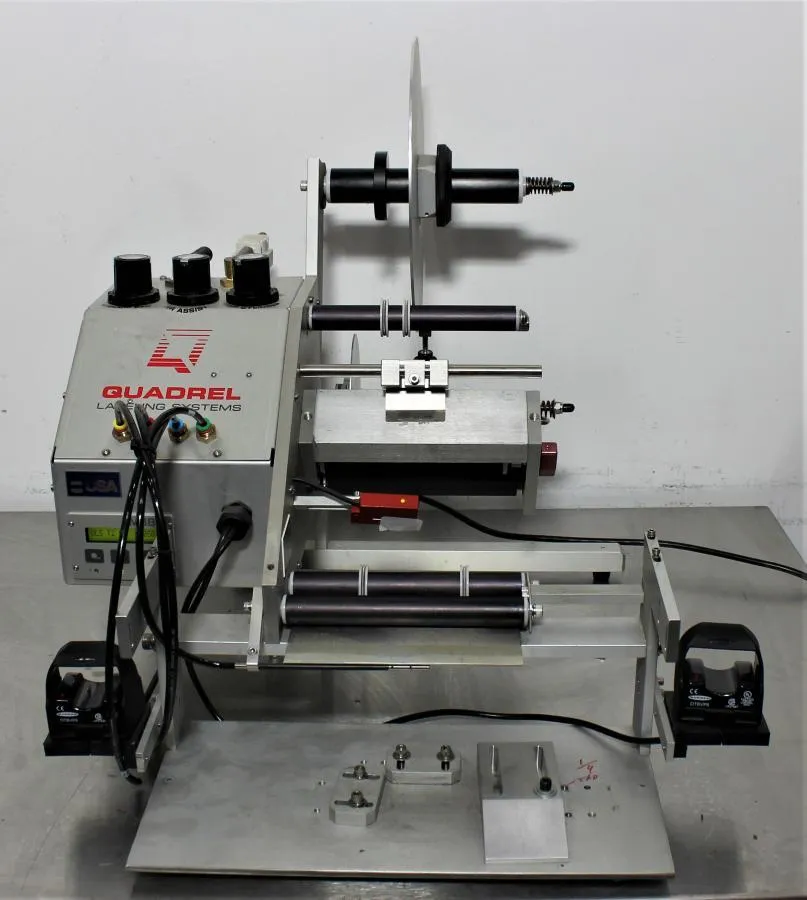

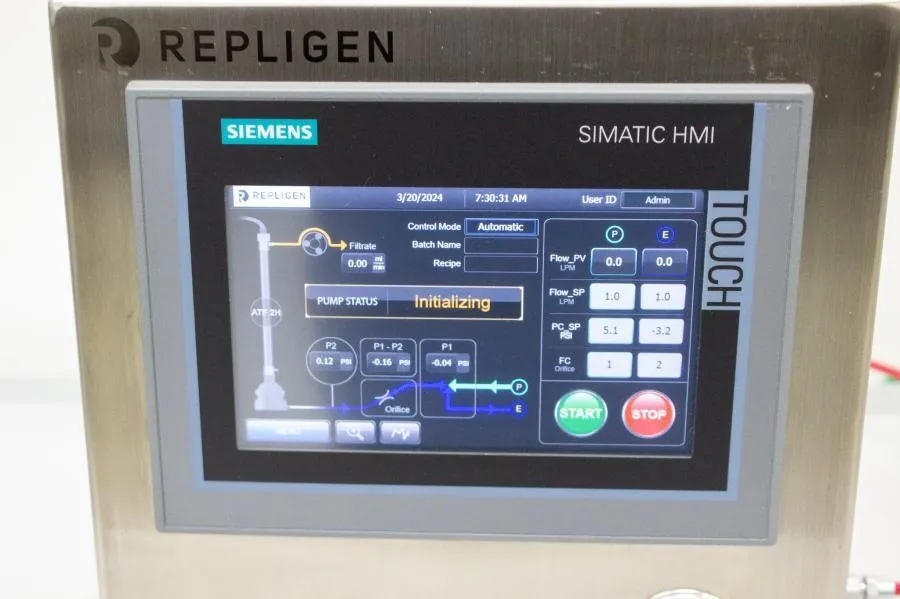

***ATF system controller is preowned with minimal wear from normal use. C24U powers on without errors. Buyer can expect the same item pictured with 30-day warranty. See photos for details.

XCell ATF® provides an efficient filtration technology for fractionating a mixture or suspension of cells, molecules or other particulates. The filtration Device includes a filtration assembly that can accept either a hollow fiber module (HFM) or a screen module (SM) for fractionation of larger particles. The filter housing is positioned between a process vessel or a bioreactor at one end and a diaphragm pump at the other end. The process vessel serves as a container for the content to be filtered. The diaphragm pump provides the means for generating alternating tangential flow (ATF), back and forth, between the vessel and pump, through the hollow fibers or screen module. During this process, a rapid, low shear, tangential flow is generated. A filtrate/harvest pump is used for controlled removal of a filtered stream. Only a single connection is required between the XCell ATF® Device and the vessel. The XCell ATF® Device can be connected to most process vessels, single use bioreactor (SUB) & a steam in place (SIP) connection.

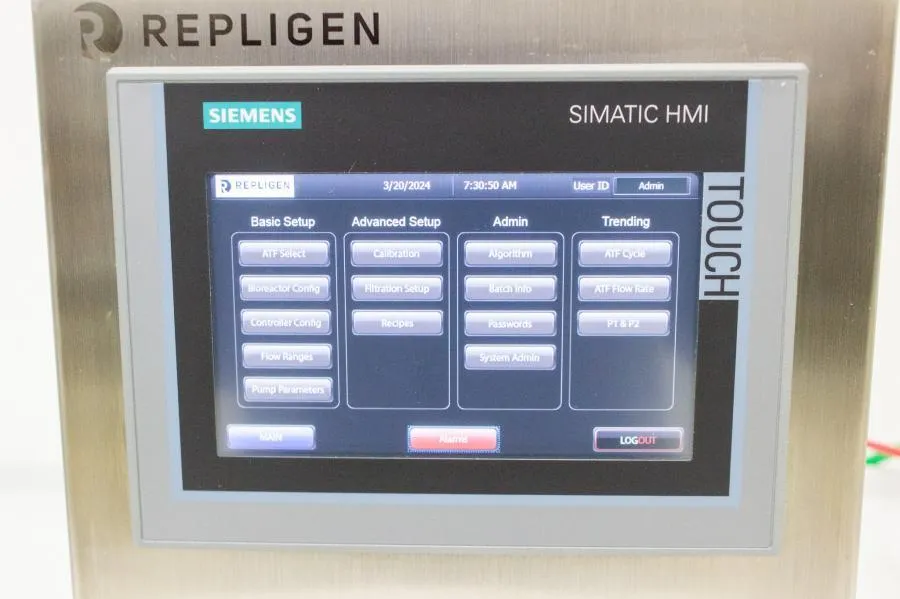

Features of the XCell™ C24 Controller (v3)

• Intended for benchtop-use

• Control of XCell ATF® Device flow rates in both pressure and exhaust cycles

• Monitoring capabilities for air flow rate and cycle time

• Set-up and selection of operation parameters

• Display of real-time process data

• Ethernet capabilities for remote monitoring and data logging

• Alarm for error conditions

• Information on algorithm performance

• Simple recipes

• Two-point calibration for pressure

• Manual mode of operation

• Power failure restart option

• Ability to have software or firmware upgrades in the field by replacing memory modules

• Ability to operate an XCell ATF® 2 Device or XCell ATF® 4 Device with standard control parameters or any variations thereof with the same hardware and software.

• Programmed to also support XCell ATF® 2 and XCell ATF® 4 Microcarrier Devices

The XCell™ C24 Controller (v3) consists of the controller, a connection for compressed air supply, a

connection for exhaust/vacuum service, a connecting air line between the controller and XCell ATF®

Device diaphragm pump, and a 0.2 micron hydrophobic filter (F1) on the air line between the

controller and ATF diaphragm pump (to ensure a physical barrier to prevent the back flow of liquid

in case of diaphragm failure). The XCell™ C24 Controller (v3) will regulate the airflow rate and

direction to establish the pressure and exhaust cycles of the XCell ATF® Device diaphragm pump.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”