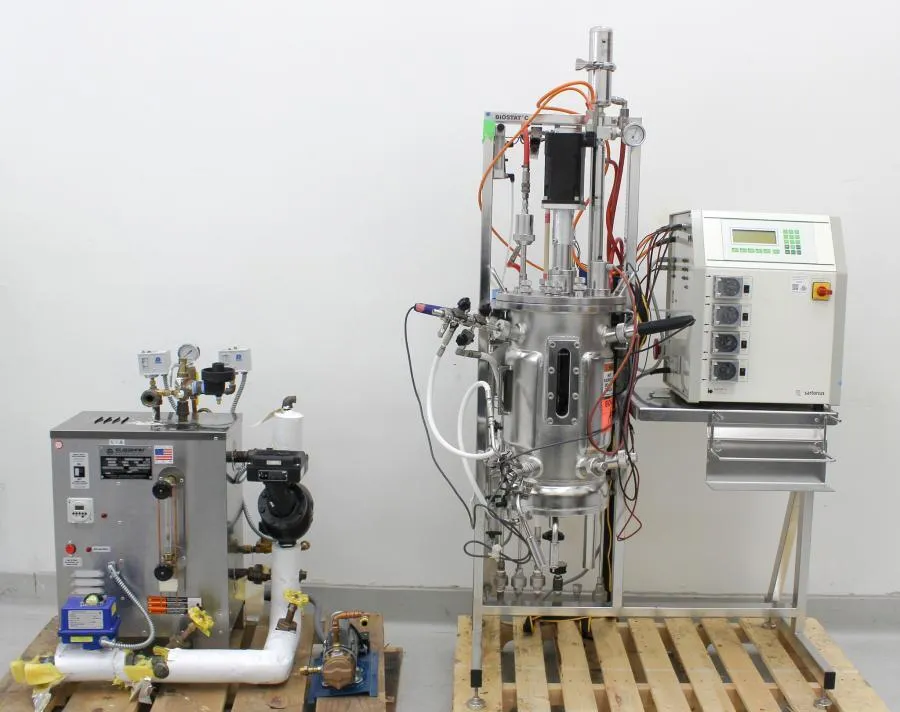

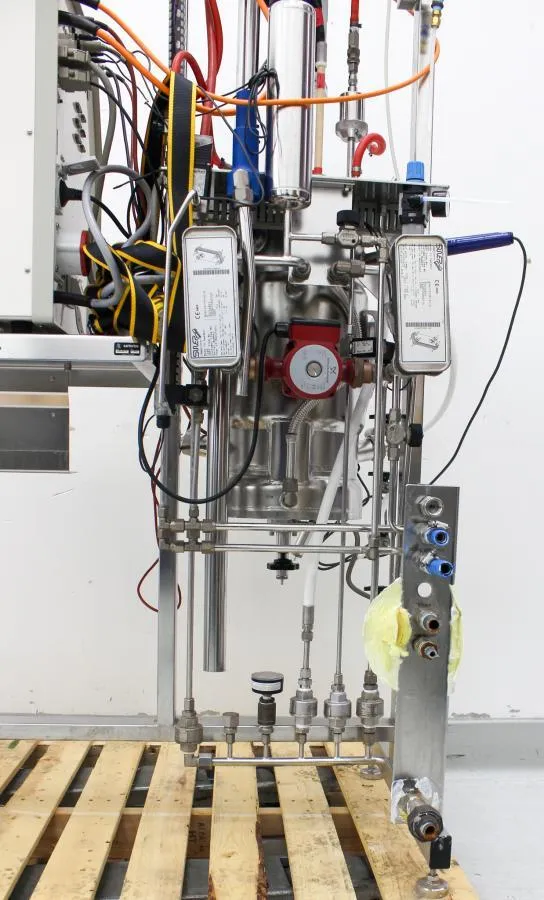

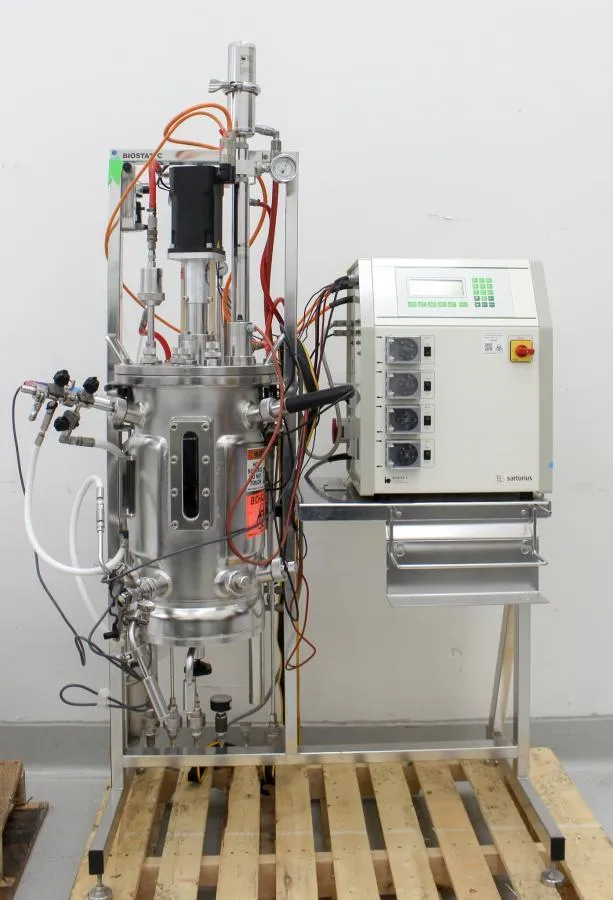

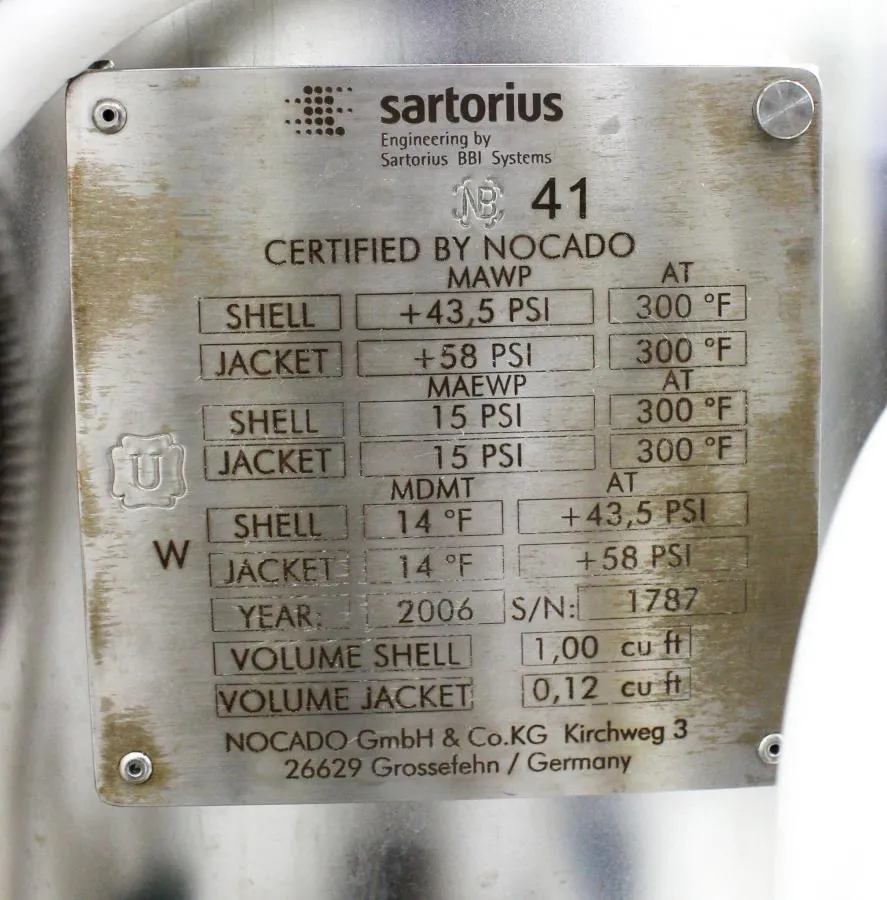

Sartorius Biostat C, Bioreactor Fermentation System 8844933 with ES12

sku: 3374182

1 In Stock

Condition :

Pre-owned

Warranty :

30-Day Warranty, 100% Parts and Labor

Region :

US

$45,000.00

Apply For Finance

Make Offer

Enquiry Here

- Make Sartorius

- Hertz 50Hz/60Hz

- Model Biostat C

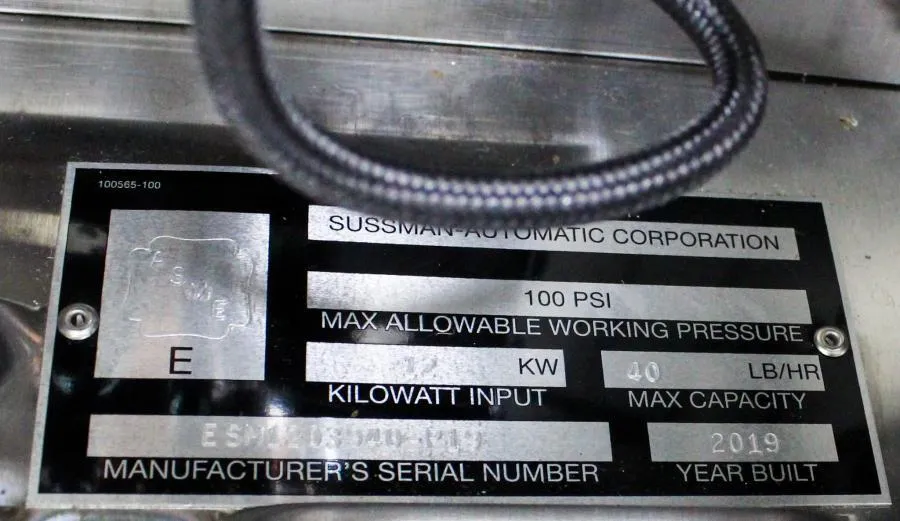

- Serial ESM1203940-P19

- Weight 600

- Voltage 220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 78×44×83 in

- Shipping Type Freight

- Item Condition Pre-owned

- Manufacturing Date 05/11/5

Sartorius Biostat C, Bioreactor Fermentation System 8844933 with ES12

**This unit powers ON without issues. Has slight cosmetic blemishes from normal use. Everything in pictures is included. Buyer can expect a working system with 30-day warranty. See photos for details.

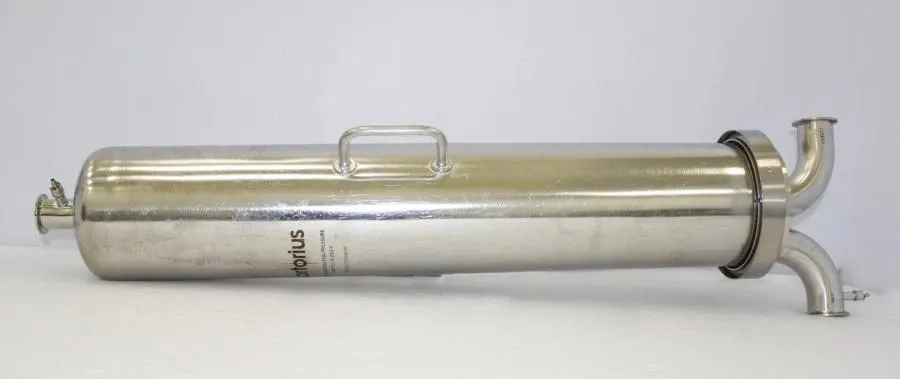

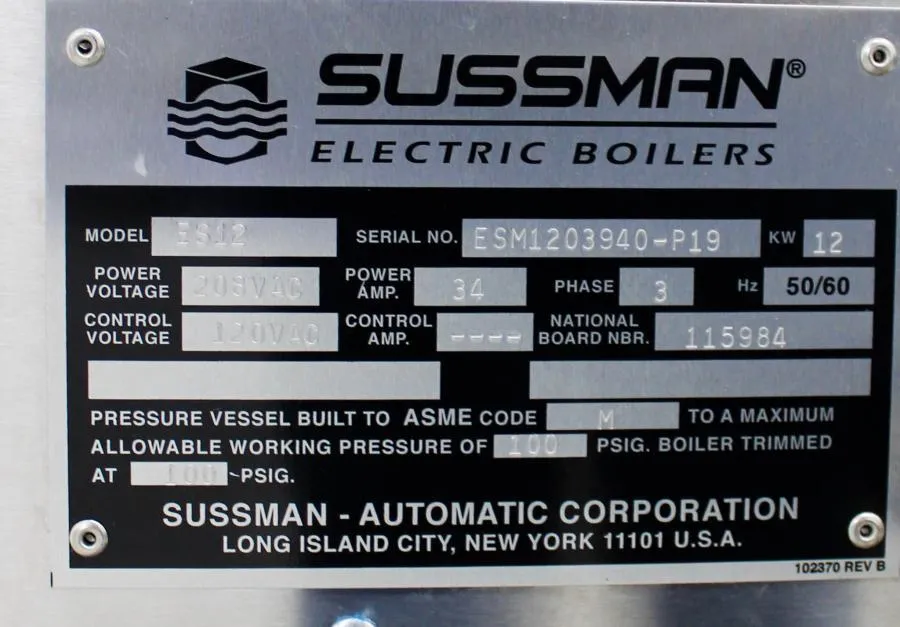

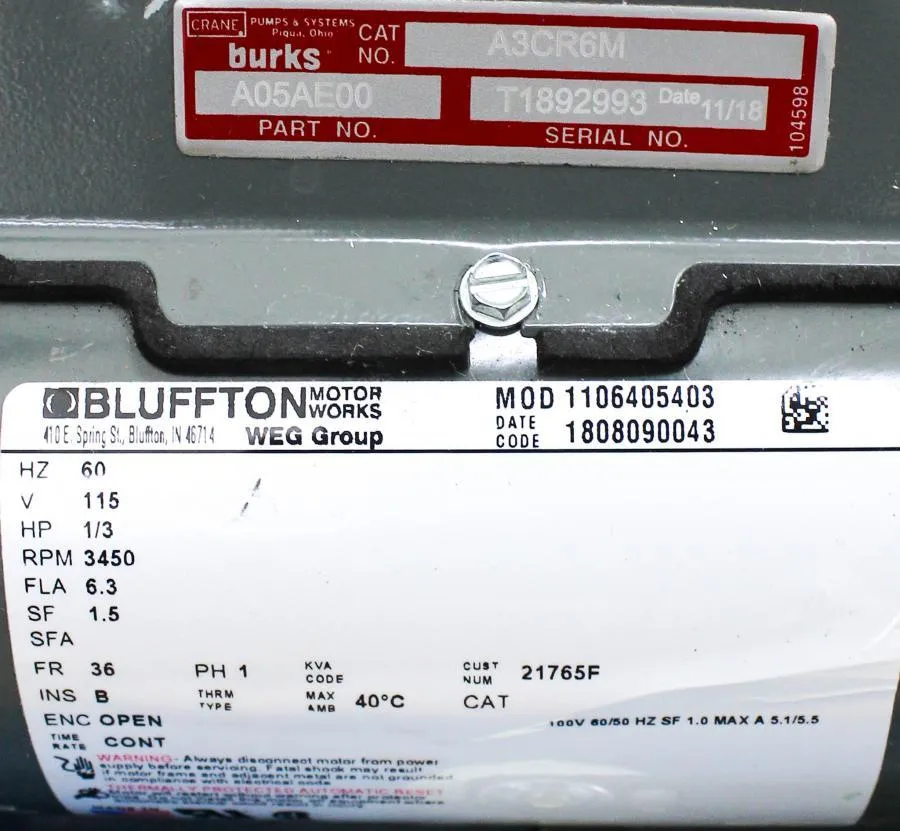

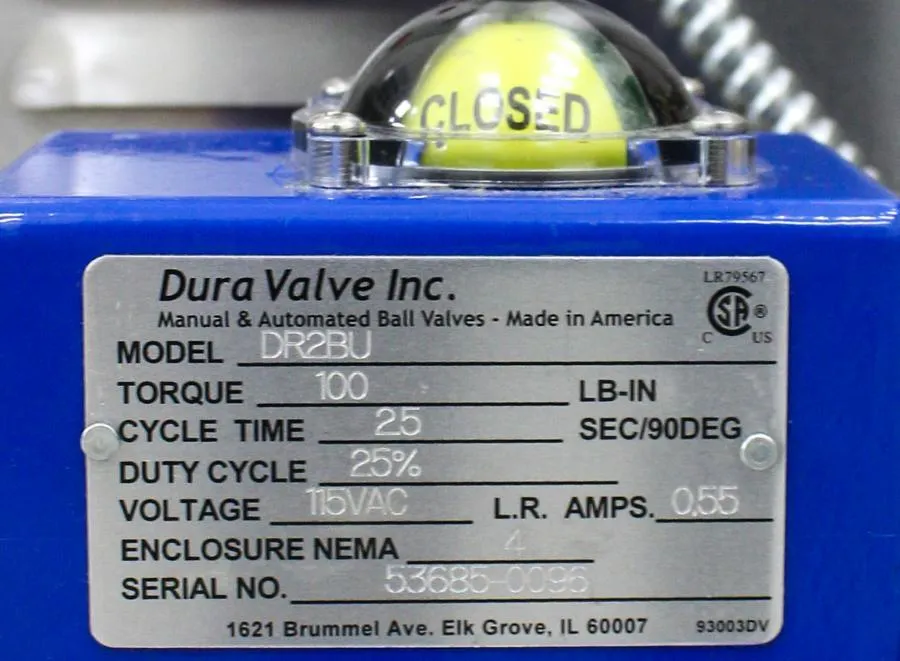

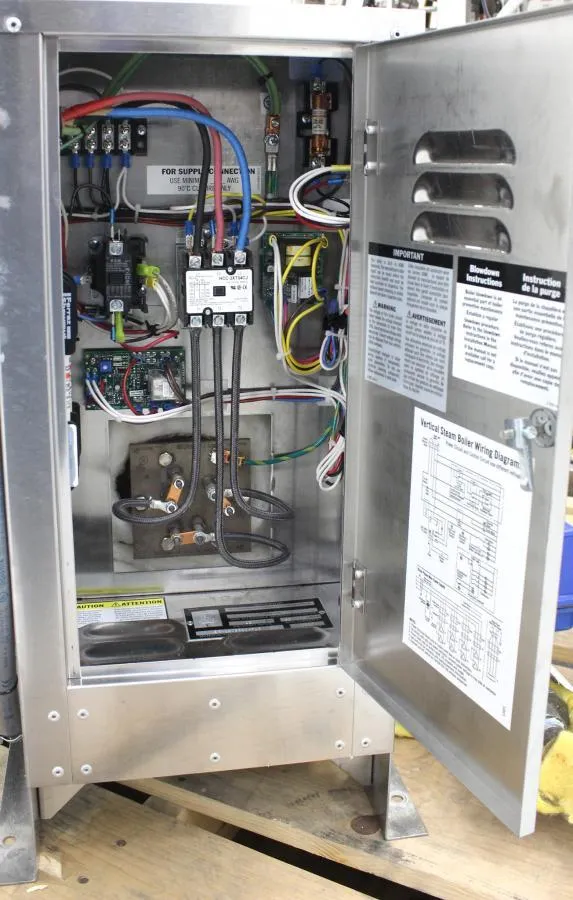

Sussman Automatic Corporation/ Chiller/ Electric Boiler ES12

Suitable for industries requiring efficient, high quality saturated steam, including laboratories, hospitals, industrial plants, pilot plants and chemical processing applications. These versatile generators are perfect for aImost any application requiring steam from 0-80 PSIG. Each unit is complete with automatic features, including pressure and liquid level controllers, ASME Code pressure vessel and safety valve and are fully tested under power. Each one must pass Sussman’s rigid quality control inspection before it is shipped. Sussman Electric Boilers - your source for fast economical steam energy.

ES Series Features:

• Safe easy-to-use heat source. No on-site products of combustion

• Easy, quick to install, they require only a water feed connection and electrical hook-up

• Applications include: Steam for tanks, reactors, distillations, autoclaves, dyestuffs, cosmetics, paraffins, glues, steam jacketed kettles, sterilizers, pipe tracing and humidification.

• Safe easy-to-use heat source. No on-site products of combustion

• Easy, quick to install, they require only a water feed connection and electrical hook-up

• Applications include: Steam for tanks, reactors, distillations, autoclaves, dyestuffs, cosmetics, paraffins, glues, steam jacketed kettles, sterilizers, pipe tracing and humidification.

WATER FEED SYSTEM: Strainer, solenoid valve, stop valve and check valve factory wired and plumbed for direct connection to water line.

• LOW WATER CUT-OFF/LEVEL CONTROL: McDonnell Miller No.150 control automatically maintains proper water level, shutting off the boiler when water supply in the boiler drops below a safe operating level.

• WATER LEVEL SIGHT GLASS : Allows constant observation of water level while boiler is in operation.

• MAIN ON/OFF SWITCH: Allows manual operation of the boiler operating control circuit.

• PILOT LIGHT: Indicates control circuit’s on/off condition.

• INTEGRAL POWER CONTACTORS: Magnetic contactors for energizing the boiler elements. Integrally mounted in the control unit.

• BLOWDOWN/DRAIN VALVES: Facilitates emptying the boiler pressure vessel and MM150 water column piping during blowdown sequence.

• LONG LIFE HEATING ELEMENTS: Industrial grade, heavy duty 0.420 inch diameter stainless steel heating elements, equipped with one piece resistance welded terminations for added

strength and safety.

• OPERATING PRESSURE CONTROL: Resets automatically to maintain preset pressure within boiler.

• ENERGY SAVINGS AND MINIMUM MAINTENANCE: Pressure vessel insulation minimizes heat loss and maximizes energy savings, insured by fibrous glass material.

• EASY CONTROL MAINTENANCE: All control panels and components are easily accessible. Fully-louvered openings avoid component heat build-up.

• NEMA 1: Louvered enclosure standard

• TRIM PRESSURE: Factory standard 100 PSIG or 15 PSIG

• LOW WATER CUT-OFF/LEVEL CONTROL: McDonnell Miller No.150 control automatically maintains proper water level, shutting off the boiler when water supply in the boiler drops below a safe operating level.

• WATER LEVEL SIGHT GLASS : Allows constant observation of water level while boiler is in operation.

• MAIN ON/OFF SWITCH: Allows manual operation of the boiler operating control circuit.

• PILOT LIGHT: Indicates control circuit’s on/off condition.

• INTEGRAL POWER CONTACTORS: Magnetic contactors for energizing the boiler elements. Integrally mounted in the control unit.

• BLOWDOWN/DRAIN VALVES: Facilitates emptying the boiler pressure vessel and MM150 water column piping during blowdown sequence.

• LONG LIFE HEATING ELEMENTS: Industrial grade, heavy duty 0.420 inch diameter stainless steel heating elements, equipped with one piece resistance welded terminations for added

strength and safety.

• OPERATING PRESSURE CONTROL: Resets automatically to maintain preset pressure within boiler.

• ENERGY SAVINGS AND MINIMUM MAINTENANCE: Pressure vessel insulation minimizes heat loss and maximizes energy savings, insured by fibrous glass material.

• EASY CONTROL MAINTENANCE: All control panels and components are easily accessible. Fully-louvered openings avoid component heat build-up.

• NEMA 1: Louvered enclosure standard

• TRIM PRESSURE: Factory standard 100 PSIG or 15 PSIG

Meeting Codes Requirements: Pressure vessel rated at 100 PSIG to ASME Section 1.

Vessel National Board Registered

• UL and cUL Listed

• Electrical construction conforms to NEC standards.

Vessel National Board Registered

• UL and cUL Listed

• Electrical construction conforms to NEC standards.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”