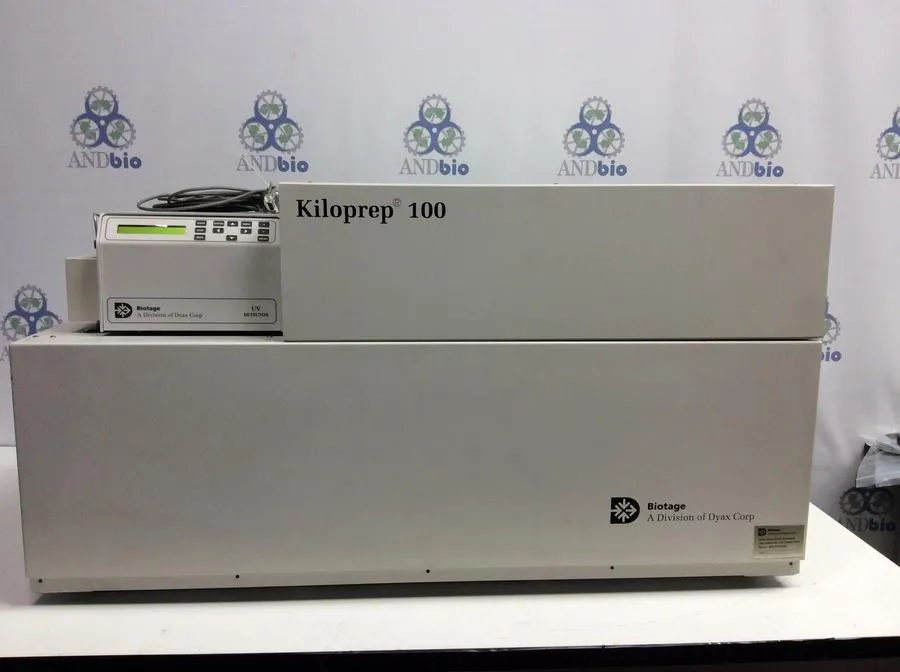

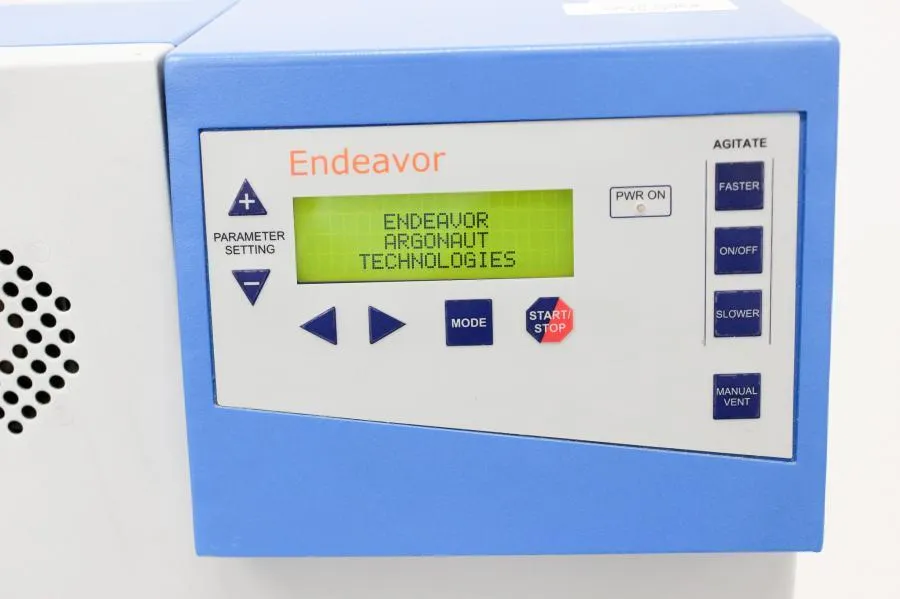

Biotage Symyx Endeavor Catalyst Screening System

- Make BIOTAGE

- Hertz 50Hz/60Hz

- Model Endeavor

- Serial 7431162

- Weight 95

- Voltage 120V/220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 23×30×25 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

Biotage Symyx Endeavor Catalyst Screening System

***Unit was tested to specifications, (mixer & heater working via control panel. Biotage Endeavor is preowned with slight wear from normal use, (missing rubber footpad.) Purchase of item included 30-day warranty. Software not included. See photos for details.

Based on Symyx Technologies' powerful core technology in screening catalysts and other related reaction conditions, Biotage Endeavor came into being; after more than thirty years of market testing, Endeavor has won broad recognition in the fields of materials and catalysis research with its precise, reliable, and durable characteristics. User trust and support. The powerful Endeavor reaction condition screening technology has been widely proven in various research and production departments, making it the gold standard for catalyst screening instruments.

Micro reaction exploration system

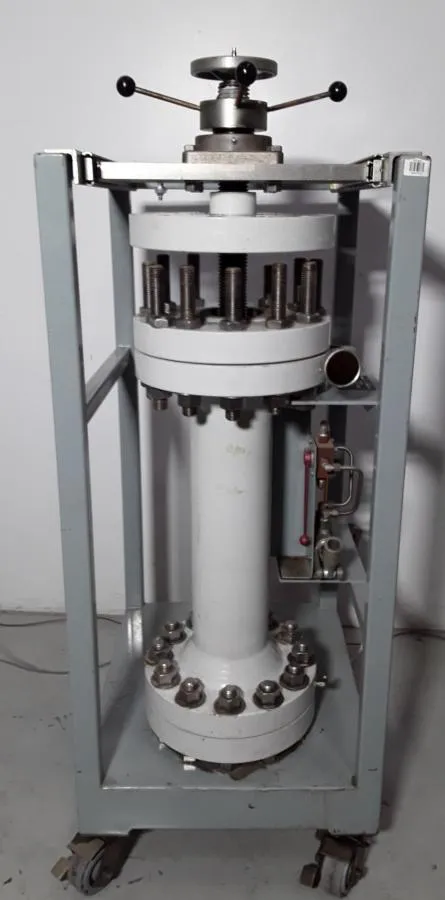

The Endeavor system can meet your needs for parallel screening of multiple reaction conditions, optimize reaction conditions, and find the best reaction catalyst. The system has eight built-in micro-reactors, which are independently controlled and operated; the original mechanical stirring is more conducive to the scale-up production of the reaction, and the precise temperature, gas and pressure control system ensures the similarity and consistency from micro-scale reactions to large-scale reactions.

In the Endeavor system, your reaction can be at normal temperature and pressure, or at high temperature and pressure, and can support any type of chemical reaction, such as catalytic hydrogenation, amide condensation, polymerization, etc. Endeavor can significantly speed up your polymerization of monomers. As well as the screening speed of catalysts, it saves you time, reduces error rates and improves efficiency.

-

Screen eight stress responses simultaneously.

-

Save time, speed up research and development, improve process conditions, and shorten product time to market.

-

Various parameters are adjustable.

-

Have more controllable data on reaction substrates and process conditions.

-

Improve your patent terms.

-

Micro reaction - save space and reduce costs.

Independent control of reaction conditions

Eight microreactors operate independently, and the conditions of each reaction can be independently controlled, helping you study the effects of temperature, pressure, catalyst, and even gas purity on reaction stereoselectivity, enantioselectivity, and yield.

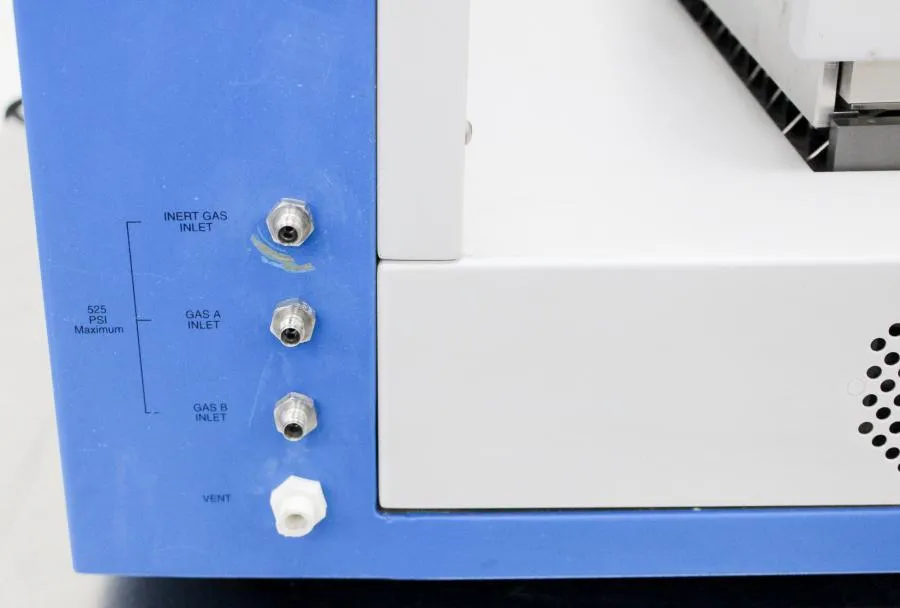

The system control panel can independently control temperature, pressure, carrier gas and stirring speed for each reactor. Reactants can be manually added to the reaction chamber, or added to the system through a syringe while stirring the reaction without pausing the reaction; the system feed port is equipped with a sealed one-way valve to ensure that the reaction system environment will not be affected by the inlet. destroyed in this way.

Endeavor can guarantee the most accurate response difference under the smallest difference parameter conditions.

Designed for parallel pressurization reactions

The system reaction temperature can reach a maximum of 200 °C, the pressure range is: 50-500 psi ( 34bar ), and can be suitable for various types of reactions. The built-in glass reaction chamber fully and seamlessly fits the stainless steel inner wall, which facilitates reaction feeding and post-processing. The replaceable stirring rod can avoid sample cross-contamination and facilitate cleaning and post-processing. Before each new feeding reaction, you only need to clean or replace the stirring rod and reaction bottle to start a new round of reaction attempts, which is simple, convenient and fast.

The reaction bottle stirrer can provide a powerful rotation speed, up to 1000 rpm , which is very effective even if the system is a viscous sample. At the same time , it can ensure continuous sample injection while stirring.

Online gas consumption detection

The gas consumption data in each reactor can be monitored online in real time to monitor the reaction process. Through the process analysis technology of gas consumption, it provides a new and rapid observation perspective for observing the progress and selectivity of the reaction process. At the same time, it provides data and ideas for further amplification of the reaction.

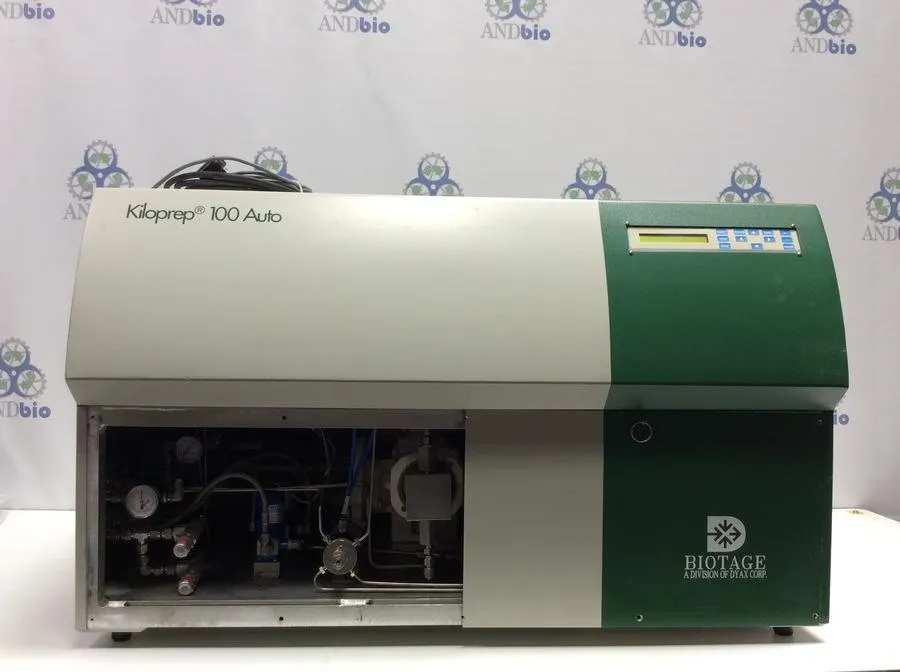

compact design

Endeavor's petite design can be easily placed in a conventional fume hood, leaving plenty of space for other equipment. At the same time, Endeavor can also be placed in a glove box to ensure water- and oxygen-free operations; the specific size is: 18 ”x 24” x 16” (44 cm x 56 cm x 40.5 cm) .

Universal and reliable software control

The Endeavor software is very simple and easy to use. You only need to enter the reaction quantity, pressure relief frequency, temperature and pressure to proceed with the reaction; the Endeavor Advanced software provides complete programming control, monitoring and customized experimental analysis.

Endeavor software requires an external computer for operation and control. It can record and monitor gas consumption and pressure changes in each reaction chamber. Chemists can monitor each reaction very conveniently and quickly, and can also view historical data for comparative analysis; the software supports exporting reaction data to Microsoft Excel or other software for analysis and drawing.

Endeavor Specifications

- Dimensions - (h x w x d)18” (44 cm) x 24“ (56 cm) x 16“ (40.5 cm)

- Weight - 90 lbs, 41 kg

- Reaction Vessels -Eight independent disposable glass reaction vessels inside 316 stainless steel

- Volume: 15mL (working volume: 5mL)

- Stirring - Continuous overhead stirring with adjustable speed up to 1000 rpm. Disposable impellers made of PEEK and are available in two types, impeller- and anchor-type

- Pressure - From 50 to 500 psi (34 bar), independently controlled for each reactor. Three gas inlets for reaction gas, inert gas and an auxiliary gas

- Temperature - Ambient to 200 C, using AllChem™ Orings. Each reactor is an independent temperature zone

- Mole consumption - For hydrogenation reactions with reaction times greater than 30 min., the relative standard deviation of the mole consumption is typically less than 10%

- TUV certified

- ASME code compliant

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”