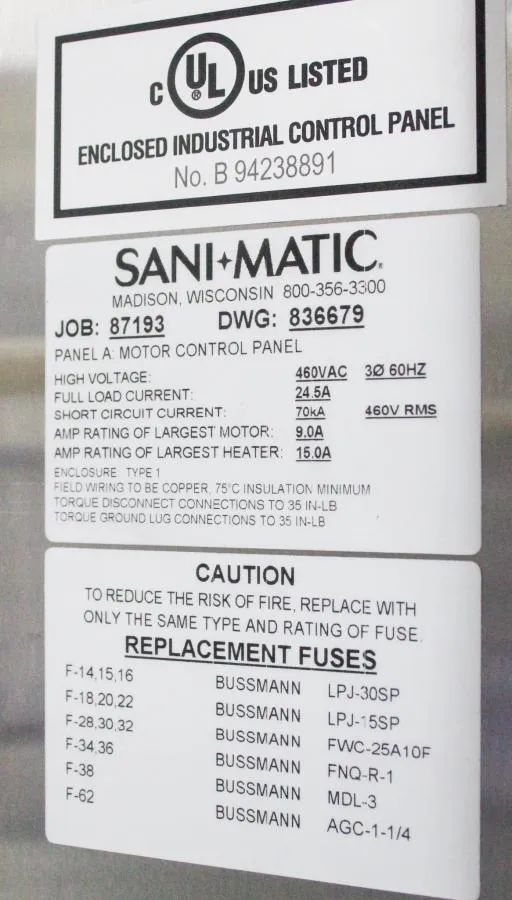

SANI-MATIC Custom Manual Clean-In-Place System, 1 Tank, CIP Skid

- Make SANI-MATIC

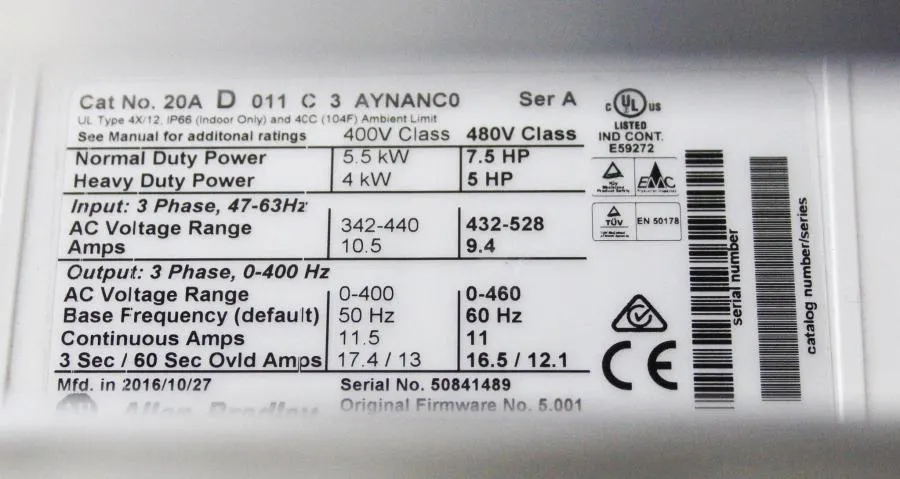

- Hertz 50Hz/60Hz

- Model Custom CIP Skid

- Serial N/A

- Weight 1

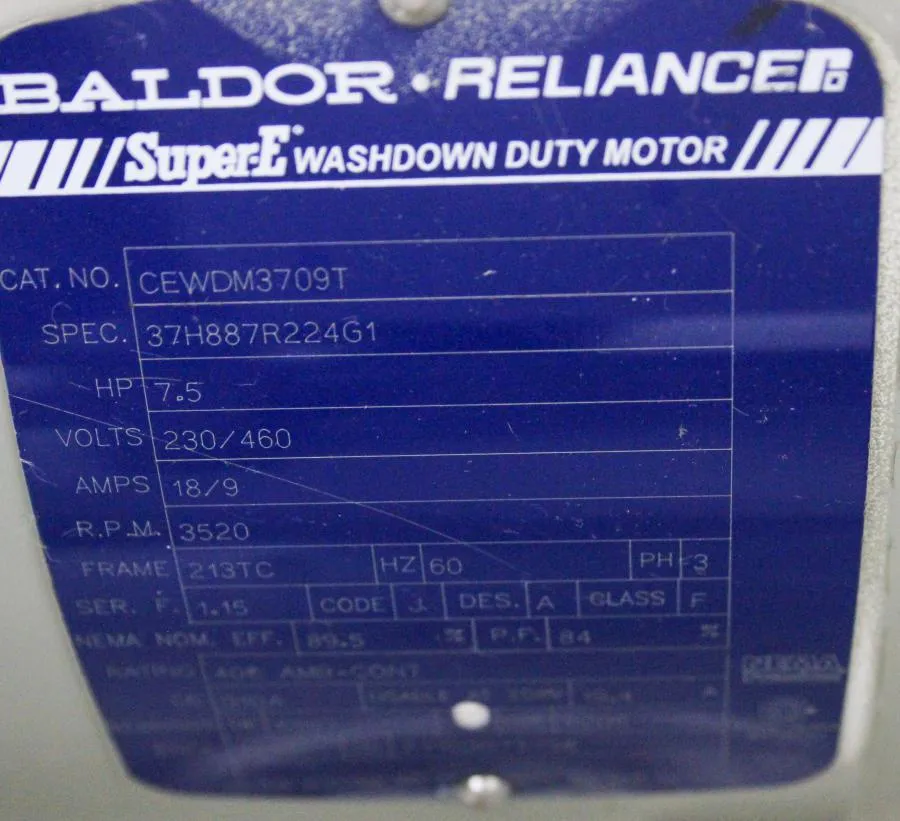

- Voltage 480V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 1×1×1 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

- Manufacturing Date 3/21/2017

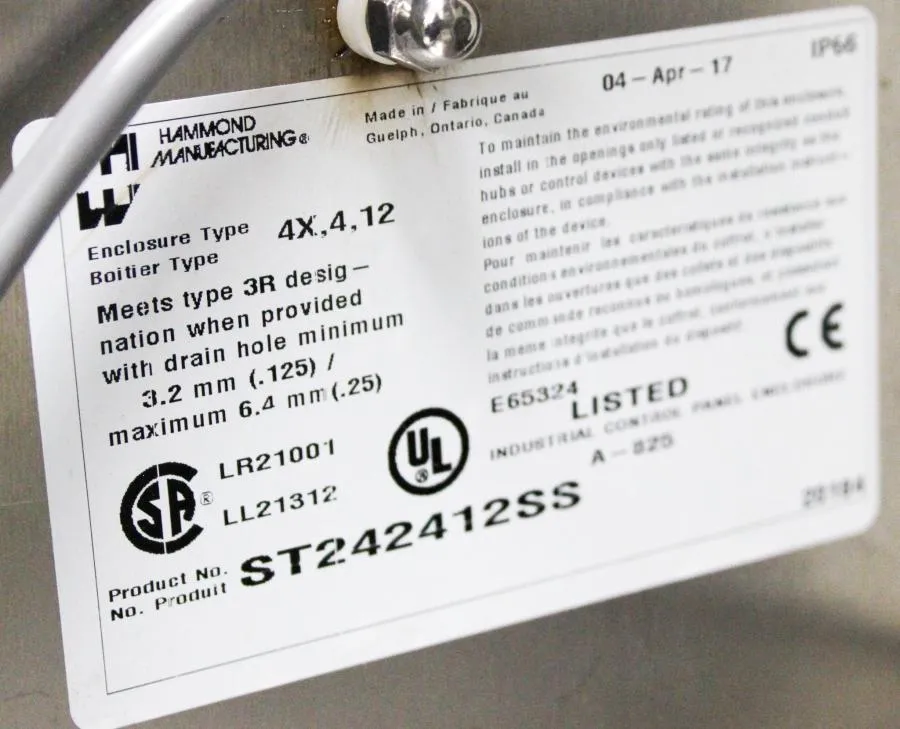

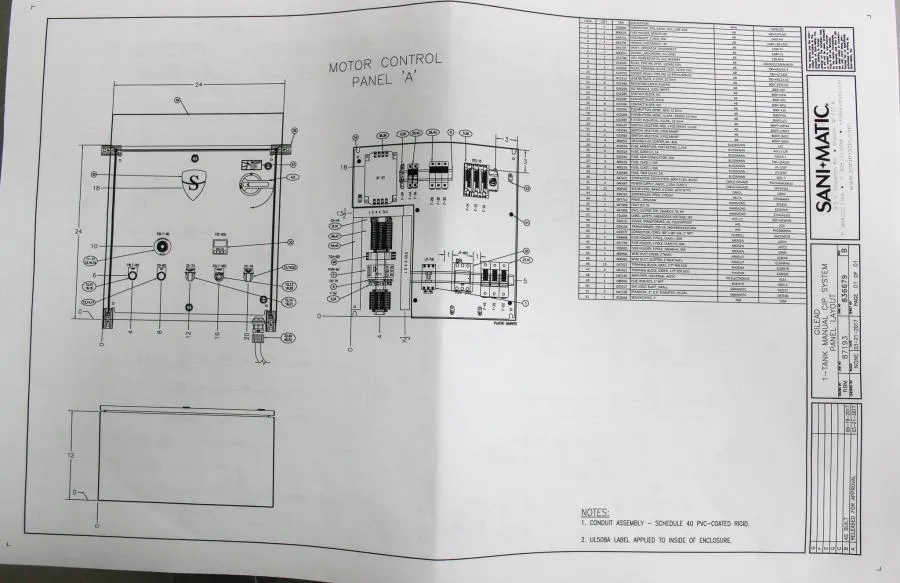

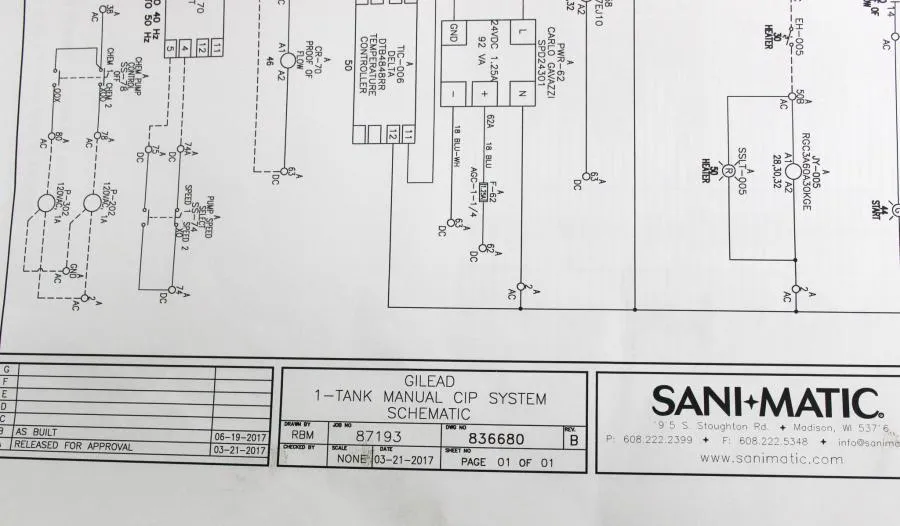

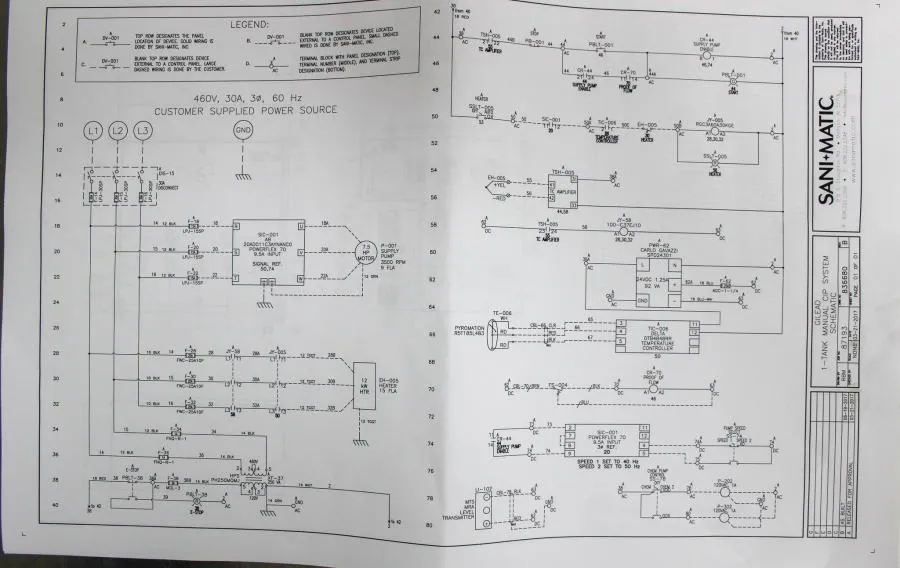

SANI-MATIC Custom Manual Clean-In-Place System, 1 Tank, CIP Skid JOB: 87193 DWG: 836679

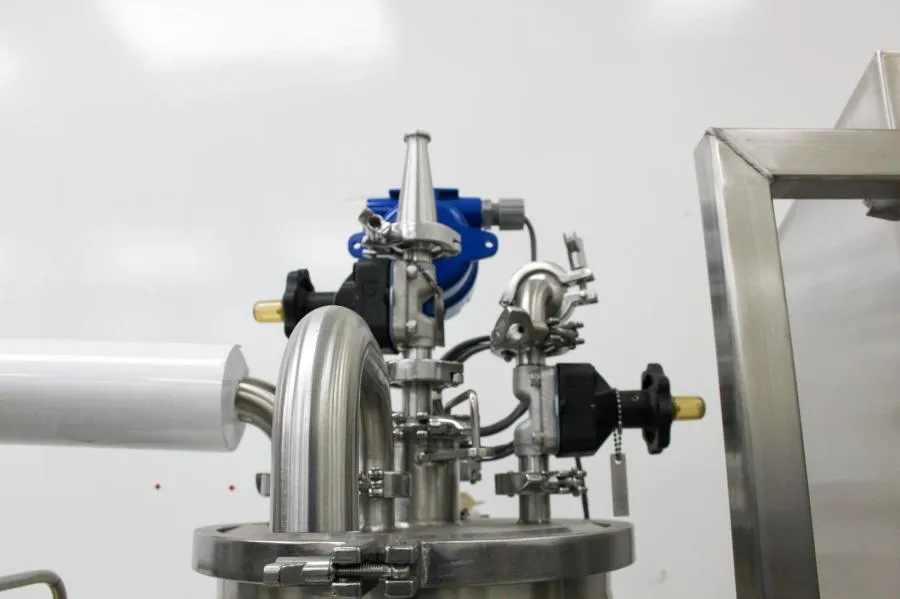

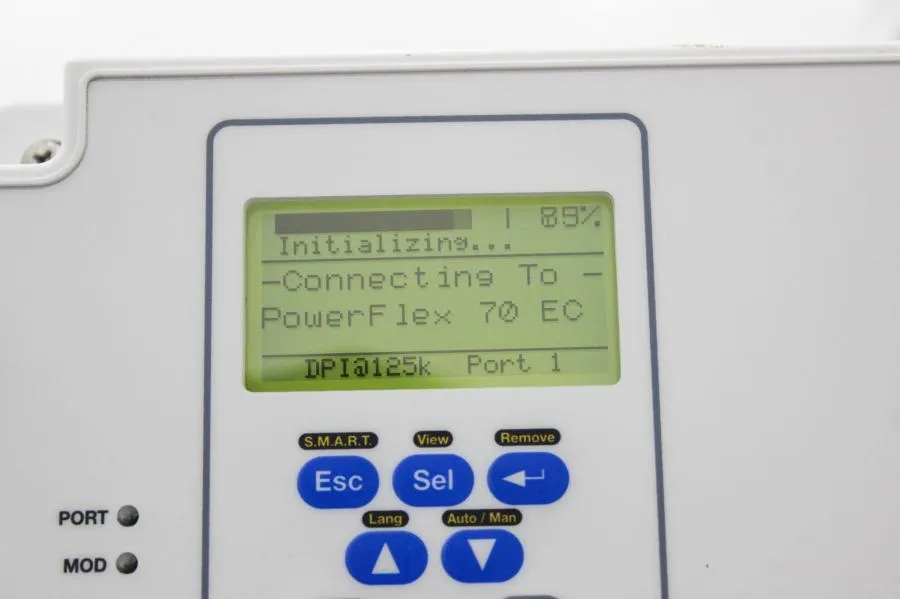

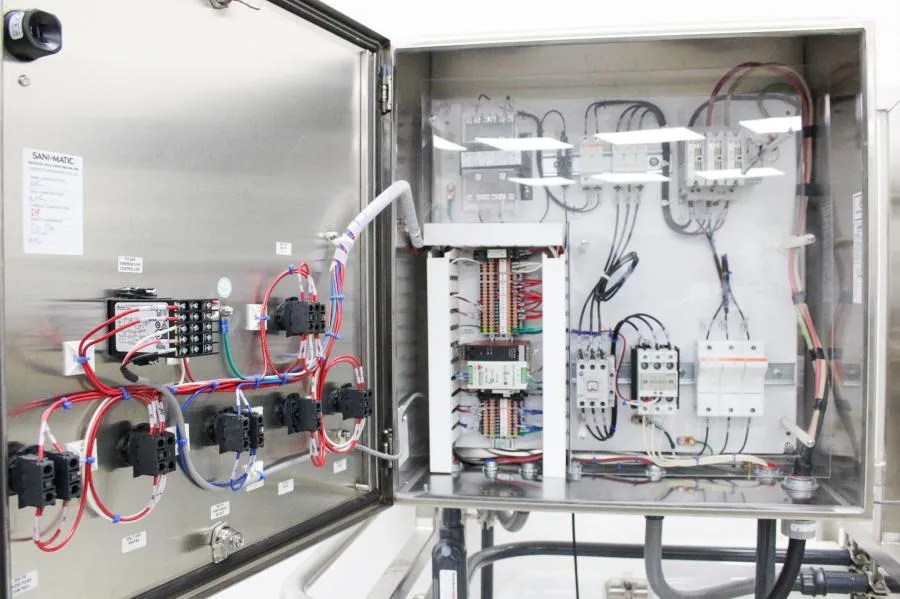

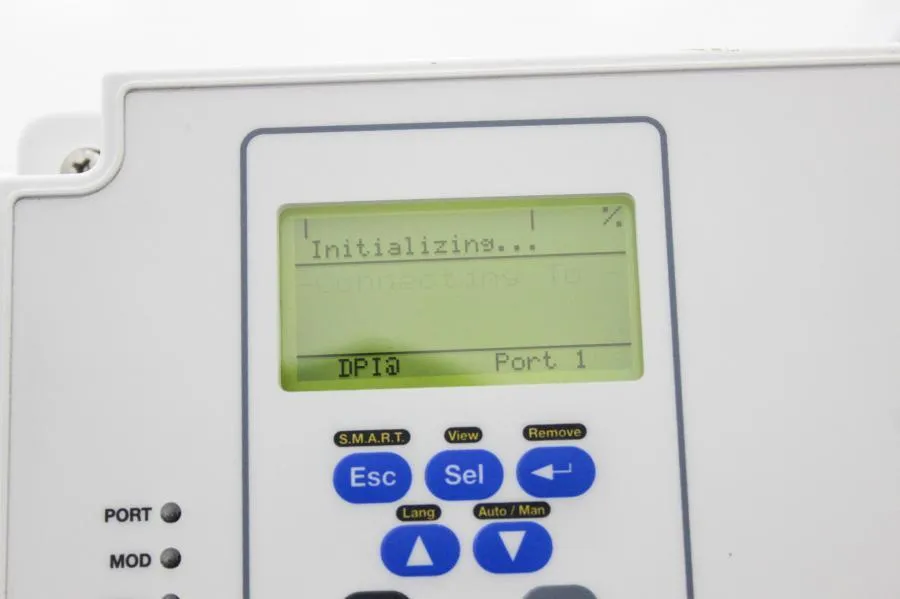

**Custom Manual Clean-In-Place system on castors was tested as far as we could. Unit powers on without errors and functions as intended. CIP skid in excellent cosmetic condition. Unit is preowned with minimal wear from normal use. Buyer can expect a working system with 30-day warranty. See photos for details.

Bio-Pharm: Custom CIP Systems

Engineered to Your Specific Plant Application and Utility Requirements

Sani-Matic Clean-In-Place (CIP) Systems are engineered to your specific plant application and utility requirements for effective and efficient process equipment cleaning. Sani-Matic’s CIP design and sizing ensure sufficient flow and appropriate pressure to thoroughly remove residue, rinse effectively, shorten cycle times, reduce operating costs, and promote worker safety. The CIP Systems meet cGMP and ASME BPE standards.

Clean-In-Place (CIP) Systems for the pharmaceutical, biotechnology, nutraceutical and personal care industries are automated systems used to clean the interior surfaces of manufacturing process pipes, vessels, tanks, bioreactors, fermenters, equipment and associated fittings, without disassembling the process. Thorough, repeatable in-place cleaning is critical to the quality of your product, the safety of consumers—and your bottom line.

Sani-Matic Clean-In-Place (CIP) Systems are engineered to your specific application, facility layout and utility requirements for effective and efficient sanitary process equipment cleaning. Our application-specific CIP design and sizing ensure sufficient flow and appropriate pressure is available to thoroughly remove residue, rinse effectively, shorten cycle times and promote worker safety.

Single-Tank CIP Systems for Single-Use

There are many bio-pharm manufacturing processes that require a single-tank, single-use CIP system such as those that need to minimize the risk of cross-contamination, optimize the solution concentration for each cycle, meet industry critical cleaning requirements, or maintain portability through a smaller footprint.

This lower initial capital investment option provides simple and flexible once-through or re-circulated wash cycles, which are programmed by our in-house programming experts to meet your specific cleaning needs.

Whether cross-contamination, space constraints, industry requirements, or initial cost considerations are the reason for implementing a Sani-Matic single-tank, single-use CIP solution, it will provide you with the confidence your process is clean, every time.

Multi-Tank CIP Systems for Decreased Cycle Times

When time for cleaning is limited but space constraints and system portability are not a concern, bio-pharm manufacturing facilities may choose a multi-tank CIP system to decrease cycle times. Adding a second tank allows both the rinse and solution wash to be at the ready—no waiting for a single tank to refill, heat and charge with chemical following the initial rinse.

Sani-Matic Clean-In-Place (CIP) multi-tank systems are engineered to your specific plant application, layout and utility requirements and our in-house programming experts design each CIP program to optimize cycle times that get you back into production faster.

1 Tank CIP – Standard Features

Single-use source of cleaning solution and rinse water

Low capital investment

Portable or stationary design

Once-through or recirculated

Minimal space requirements

APPLICATIONS

PROCESS TANKS • PROCESS LINES • PROCESS EQUIPMENT • MIXERS, BLENDERS • BIOREACTORS • FERMENTERS • SPRAY DRYERS, COATERS • HOSES • IBCS • FILLERS, FILLER PARTS

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”