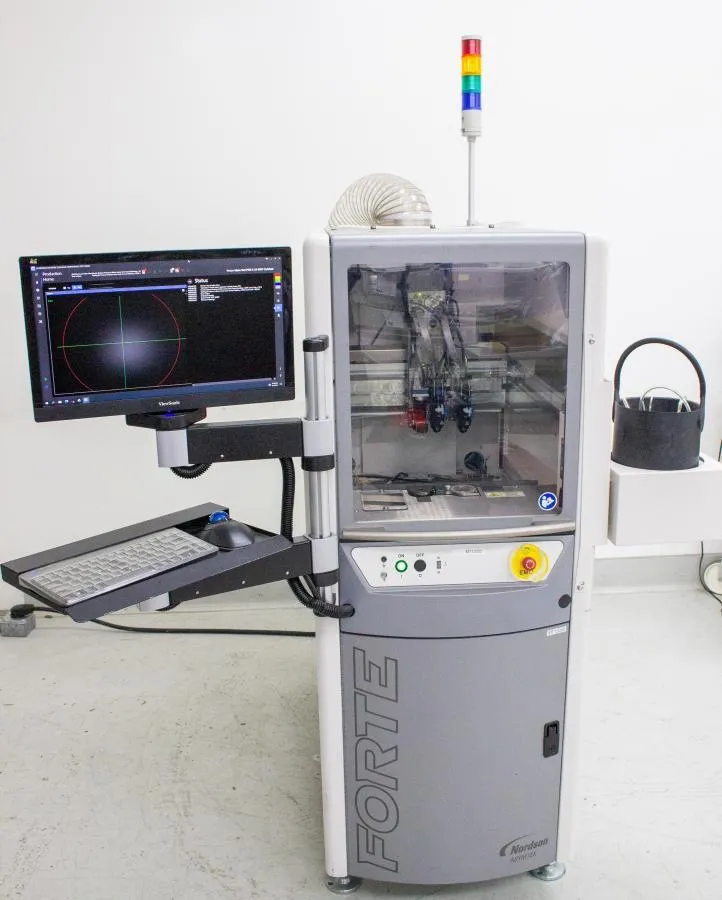

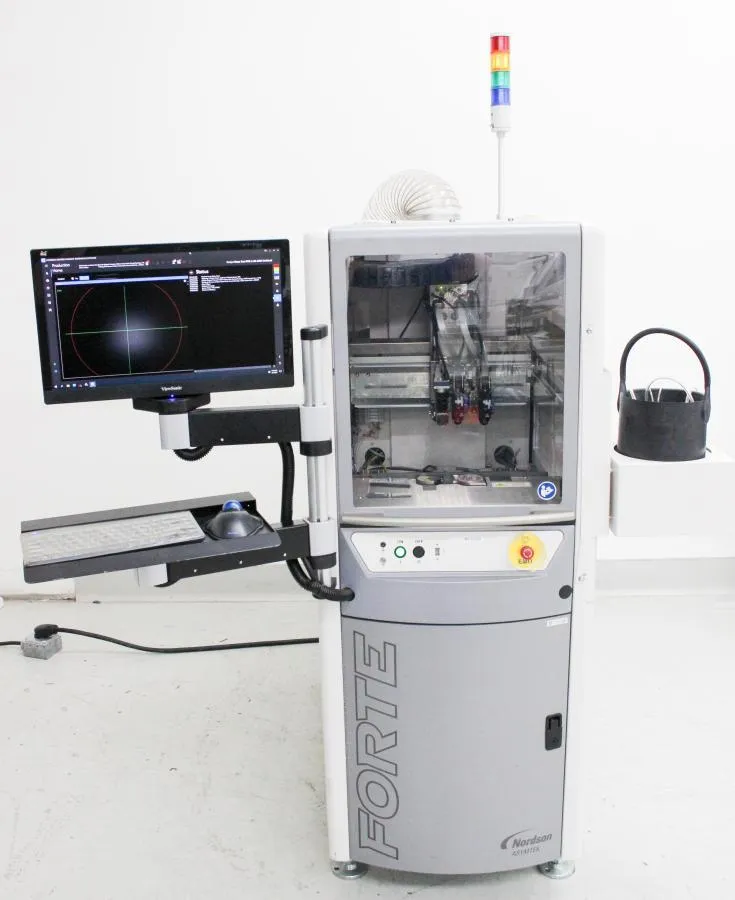

Nordson Asymtek Forte Series Fluid Dispensing System

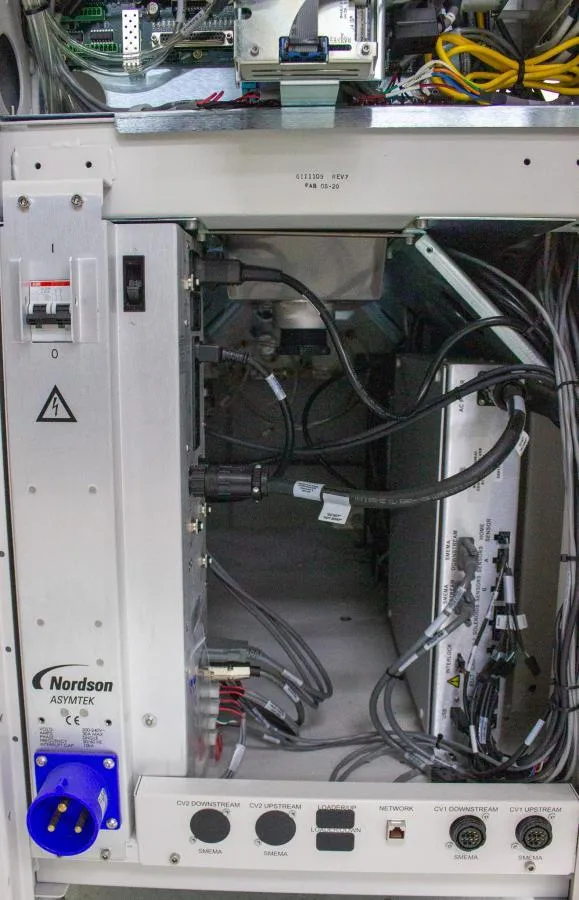

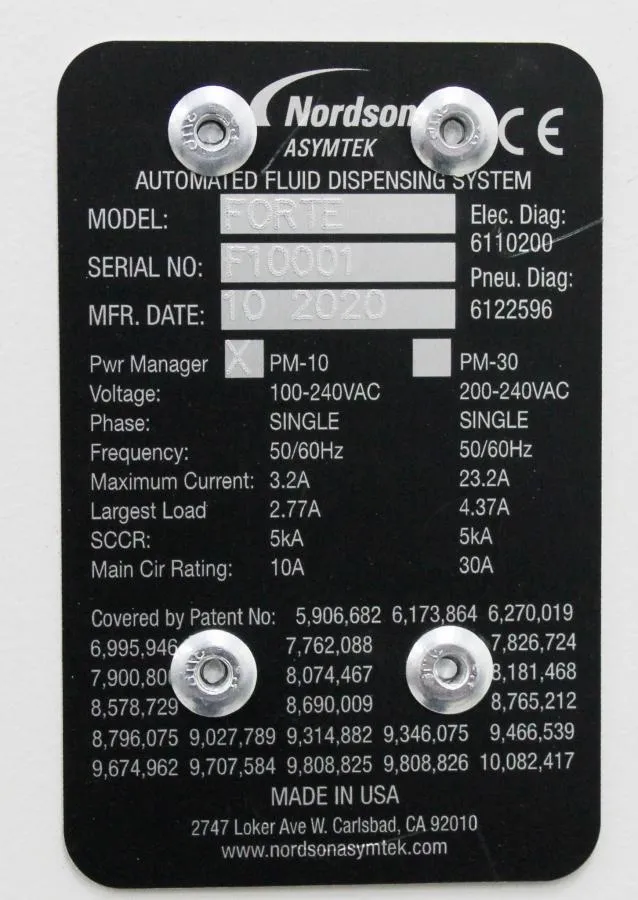

- Make Nordson

- Hertz 50Hz/60Hz

- Model Forte

- Serial F10001

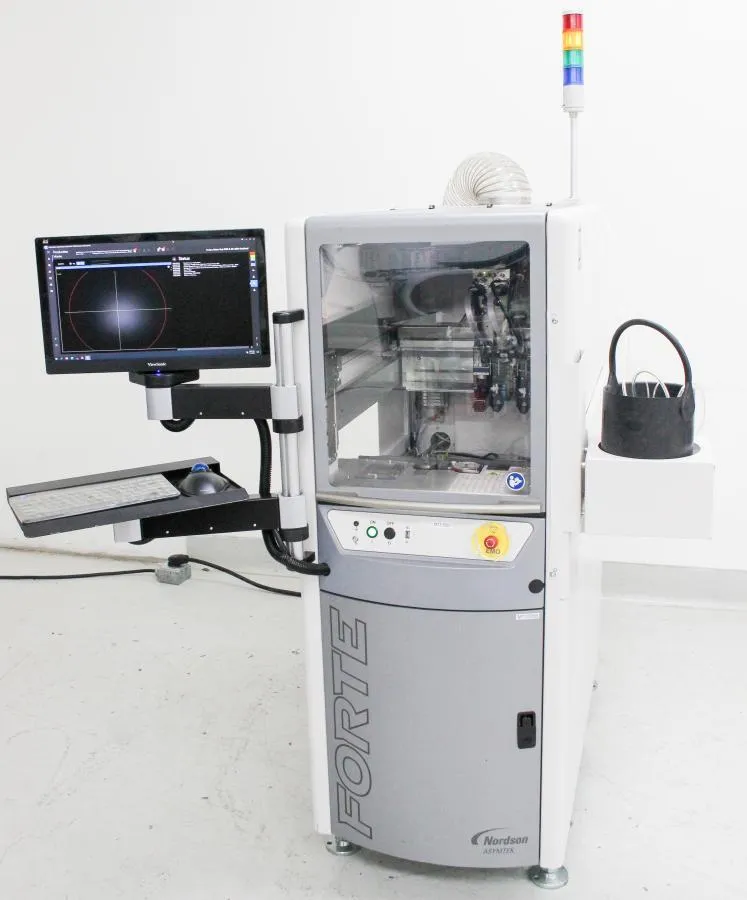

- Weight 950

- Voltage 120V/220V

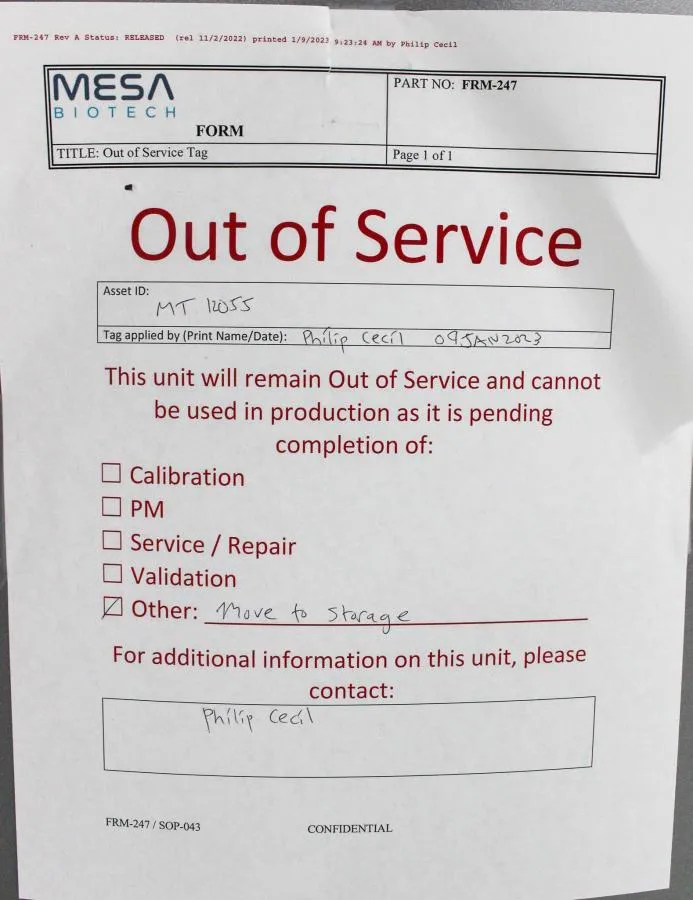

- Working Not Working

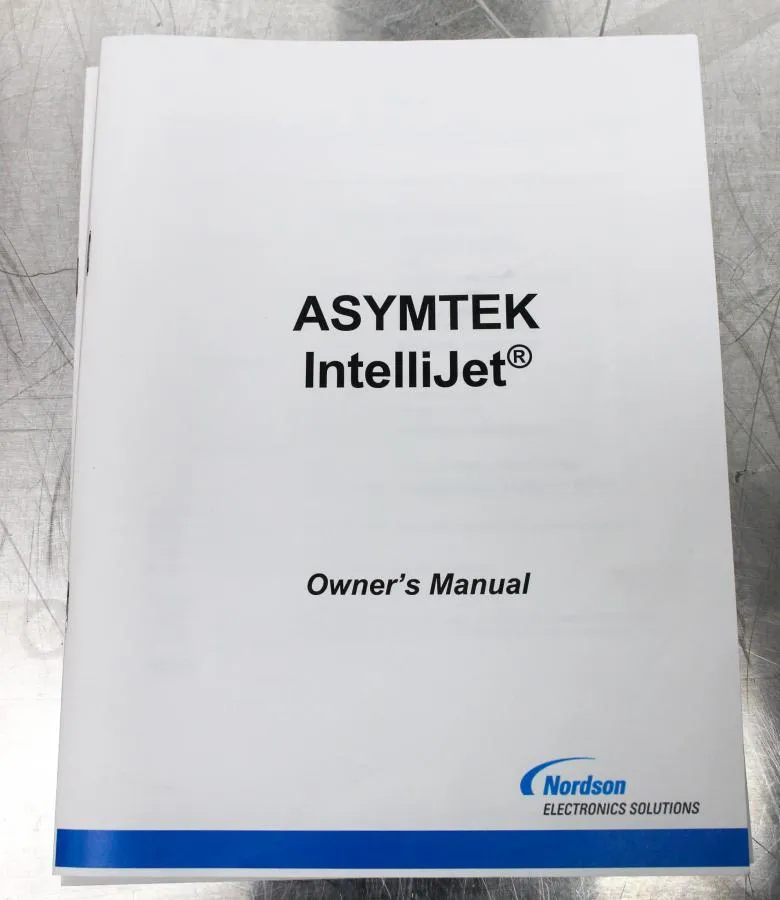

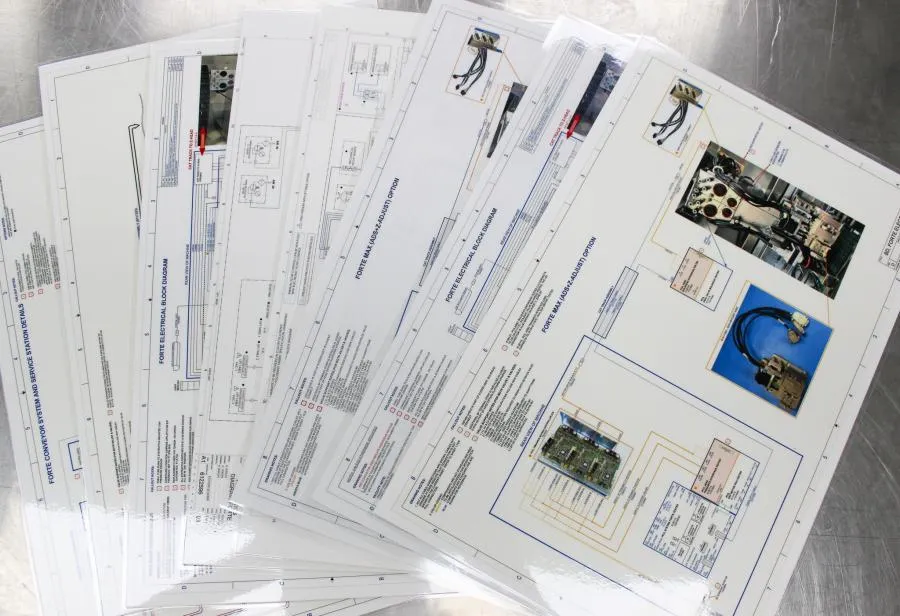

- Includes Computer with Software|User Manuals

- Warranty AS-IS

- Dimensions 57×27×73 in

- Shipping Type Freight

- Item Condition Needs repairs

- Manufacturing Date 10/2020

Nordson Asymtek Forte Series Fluid Dispensing System

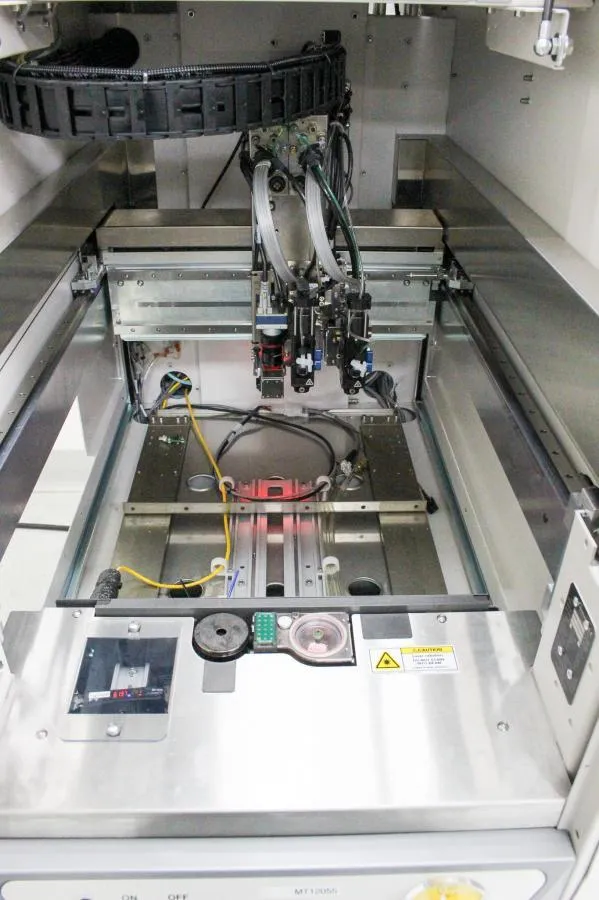

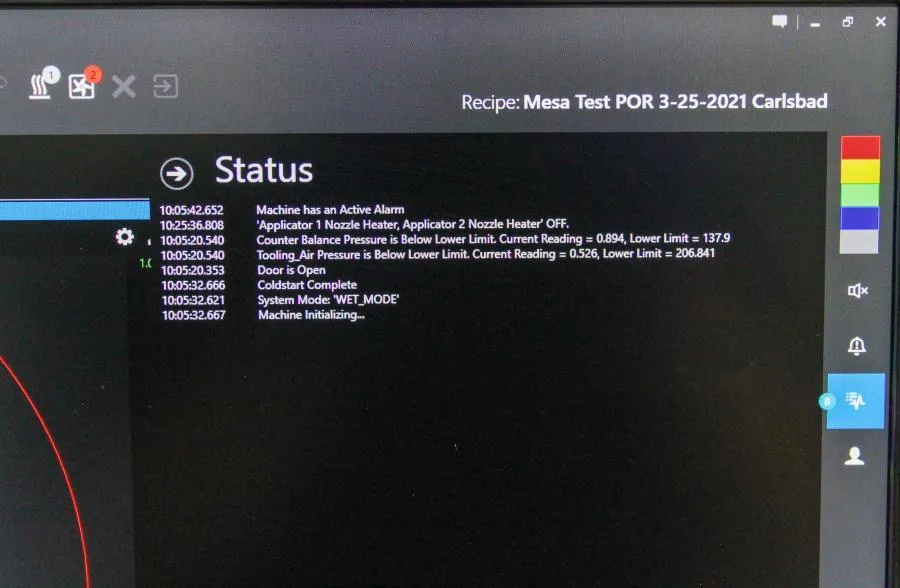

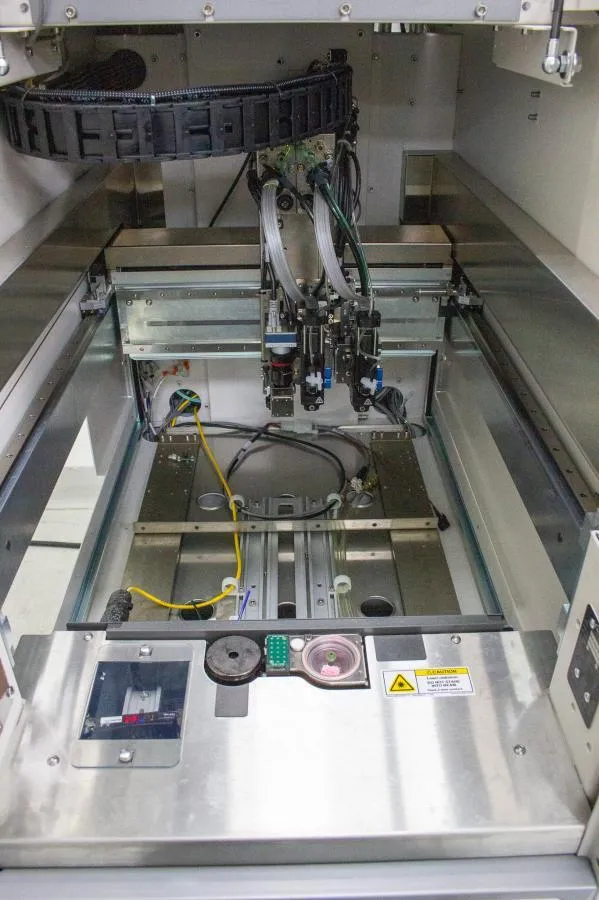

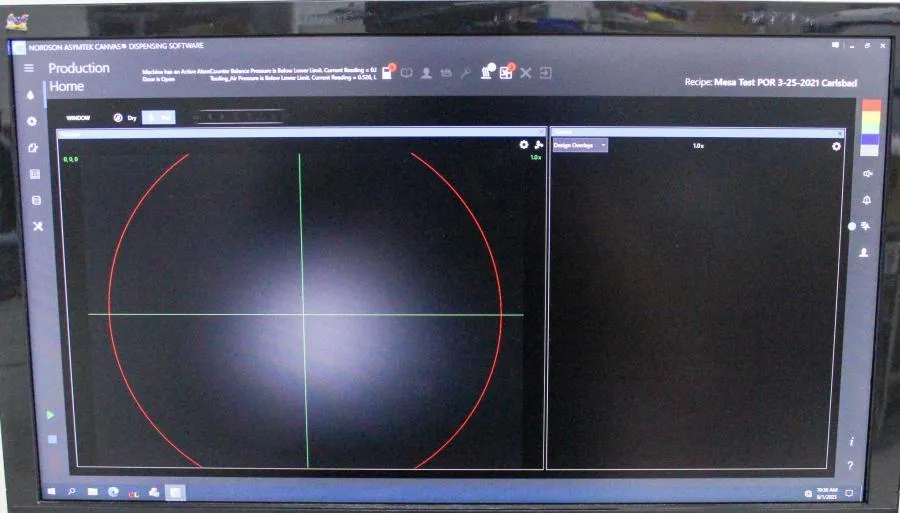

***This unit is for sale AS/IS. Unit was tested as far as we could. Unit powers on & able to communicate with software. Unit has slight wear from normal use (shuttle carriage missing). See photos for details.

Exceptional dispensing productivity and accuracy for high-volume consumer electronics, printed circuit board assembly, flexible circuit, MEMs, and electromechanical assembly applications.

Overview

Next-generation and time-tested capabilities are combined in this upgraded system to increase productivity by up to 50% over the top-selling Spectrum® ll, all in a space-saving footprint. Improve UPH with swift acceleration, enhanced motion control, and IntelliJet® compatible Forte MAX dual-valve dispensing.

- The Forte Series supports vital consumer electronics applications, including precise coating, underfill, dam and fill encapsulation, printed circuit board assembly, flexible circuit assembly, EMA, and MEMs.

- Modern and intuitive Canvas® dispensing software provides simplified programming; process control,

monitoring, and simulation; data insights; and on and offline programming. - IntelliJet® ready Forte MAX dual-valve jetting

- Shifted parts won’t slow you down. The Forte MAX dual-valve system is equipped with patented*

real-time correction to automatically adjust for skewed parts and component height variation in

the x, y, and z-axis. - Dispense a single fluid type from two identical valves with dual-simultaneous dispensing.

- Dispense two fluid types from two separate valves with dual-action dispensing.

- • A standard integrated dual-valve service station, patented* closed-loop process controls, and nozzle

cleaning rail reduce operator maintenance and intervention.

The Forte Series - A space-saving footprint for maximum production floor efficiency.

- 1.5 g acceleration for blazing fast point-to-point moves.

- Forte MAX – IntelliJet ready, dual-valve dispensing for optimal throughput.

- Patented* real-time skew correction for better wet dispense accuracy and yield.

- Fast, repeatable setup with automated calibration.

- Closed-loop controls and data traceability keep your process on point.

- Advanced Canvas® fluid dispensing software.

- Industry 4.0 Connectivity Ready – Integrate Nordson dispensing equipment with your FIS or MES using the ASYMTEK NE Connect API and Software Developer Kit (SDK) standard in Canvas software.

*Nordson US Patents 9,707,584; 10,150,131; 10,737,286 and other patents pending.

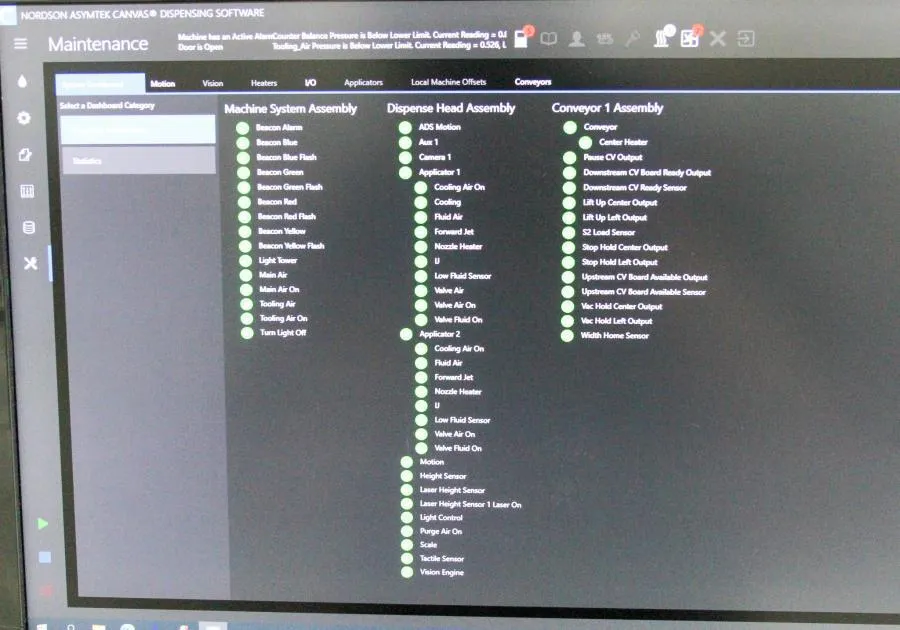

ASYMTEK Canvas Software

Canvas® software delivers a completely new interface that simplifies your programming tasks and provides powerful insight and control over your process. Specifically built to enhance the performance of the Vantage® and Forte™ Advanced Fluid Dispensing Systems, Canvas puts the power of graphical programming to work

Overview

Canvas software includes well-known, reliable Fluidmove® software features – such as Fids-on-the-Fly (FoF), Integrated Mass Flow Calibration (MFC), and Calibrated Process Jetting (CPJ) – along with a reimagined work flow and onboard guidance for greater process success.

Benefits

- Intuitive Graphical Programming – Simplifies Programming Tasks

Scan your workpiece, develop a program and simulate the dispensing results on a virtual canvas prior to dispense. - Guided Wizards – Walk You Through the Process

Follow step-by-step instructions to create workpieces, patterns and dispensing instructions. - Data Monitoring – Supports Continuous Productivity

Monitor system sensors and data in user definable graphs and data tiles. Add graphs to any panel, get detailed diagnostic history from system logs and events, monitor temperature, pressure and flowrate. Status Bars provide an overview of the entire system at-a-glance. - Personalized Layouts – Save Time

Move, resize, hide and arrange windows to create a custom display of the information you want to see – and nothing else. - Offline Programming – Avoids Process Interruption

Develop recipes without interrupting your dispensing process. Transport your scanned workpiece to an offline programming station and create or edit your dispensing recipe at your desk.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”