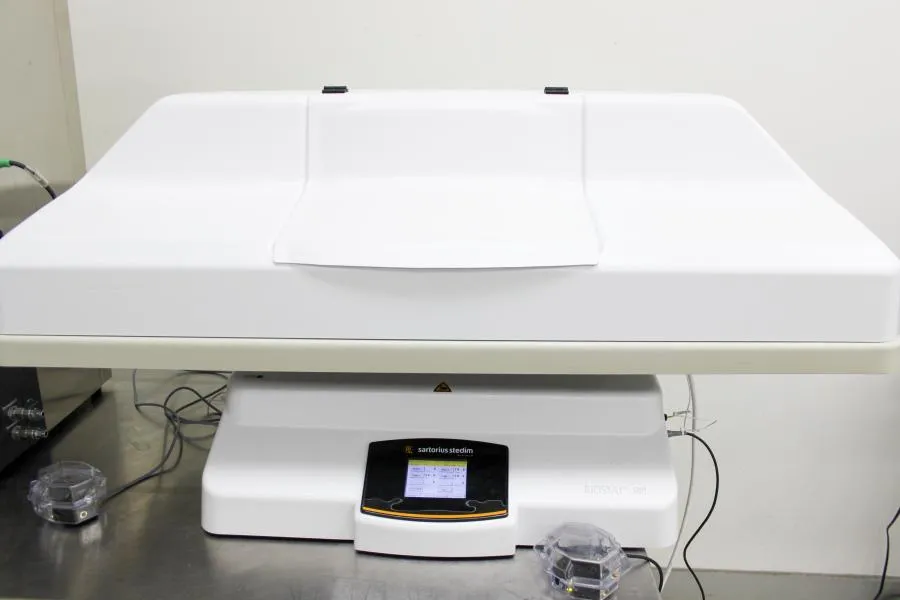

Sartorius Stedim Biostat B Bioreactor Controller w/ Dual Wave Rocker RM 20/50

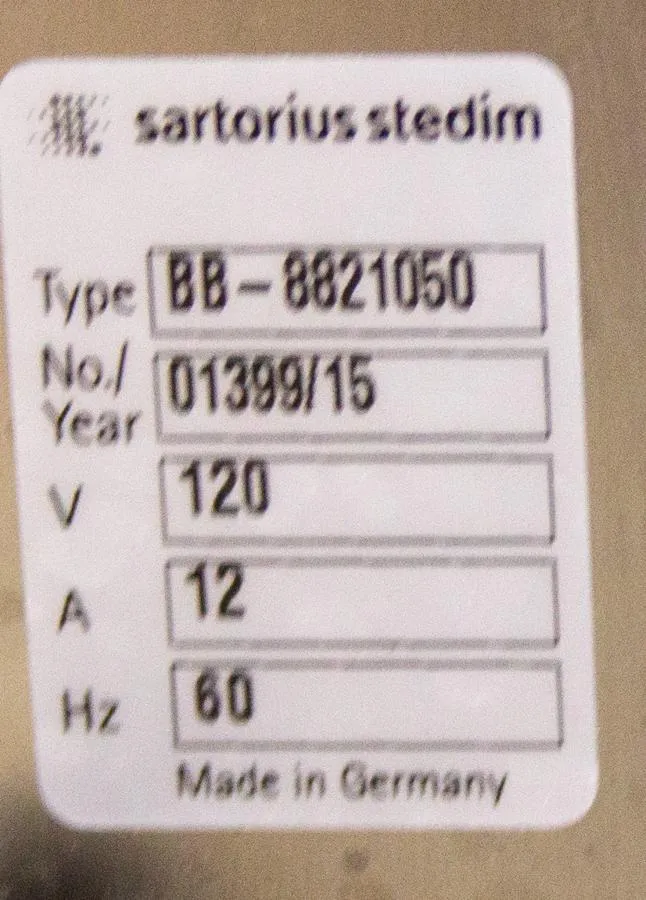

- Make Sartorius Stedim

- Hertz 60Hz

- Model Biostat B w/ RM 20/50

- Serial 01399/15

- Weight 1

- Voltage 120V

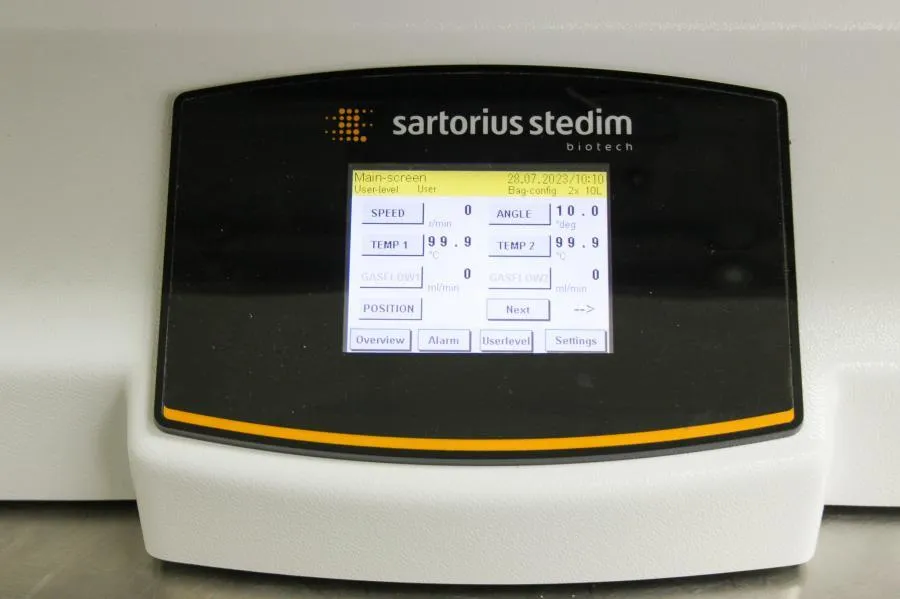

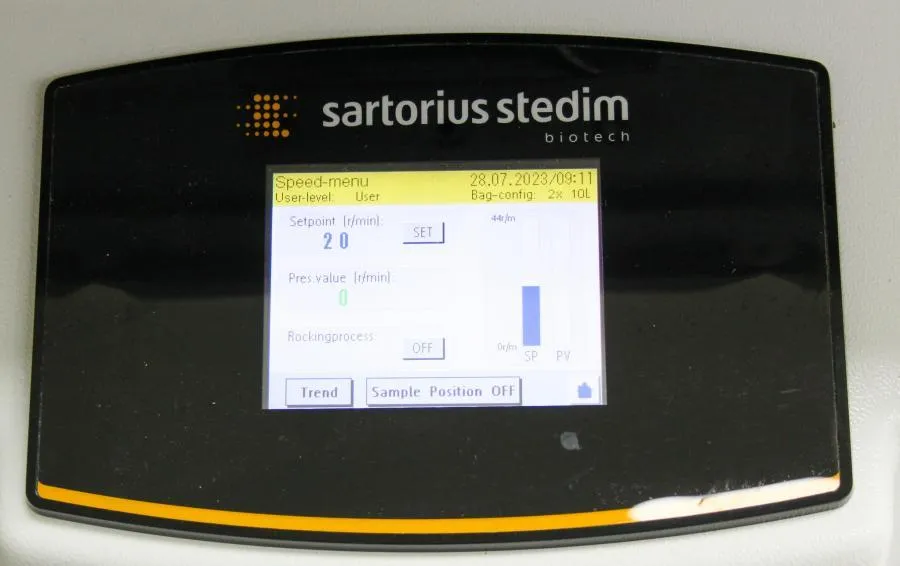

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

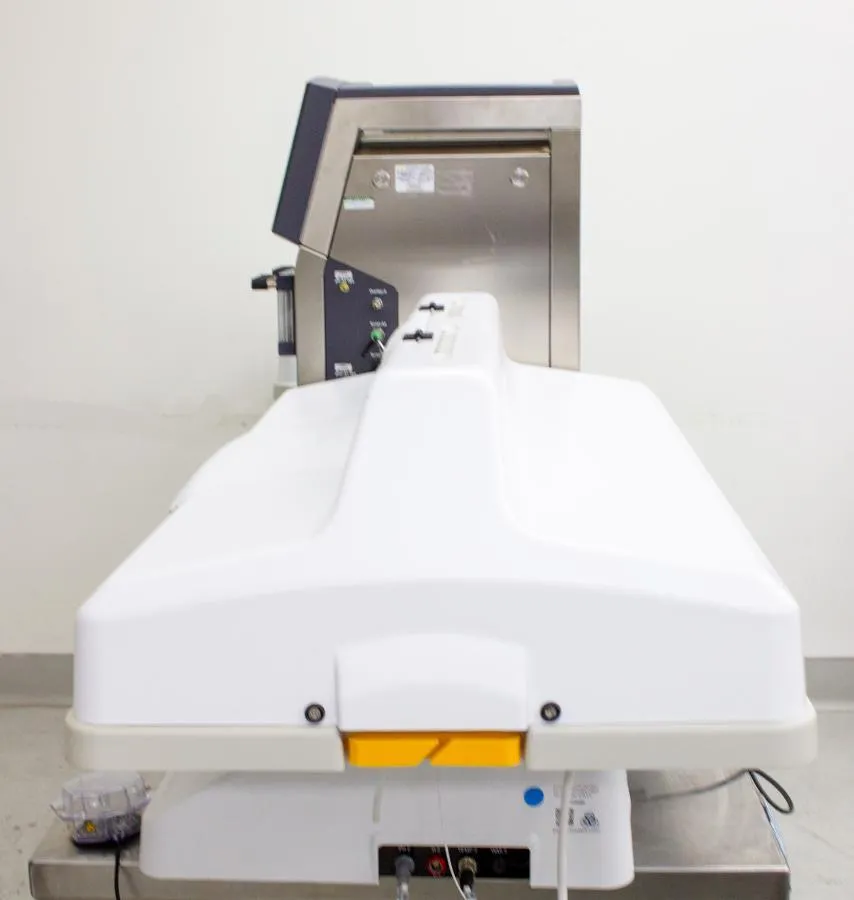

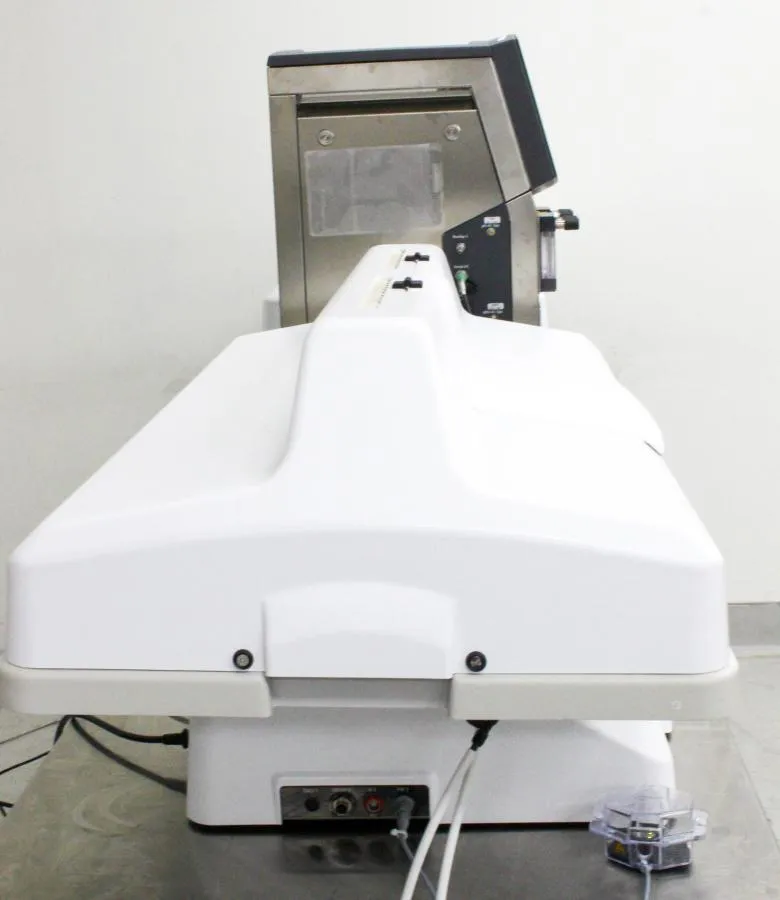

- Dimensions 28×47×27 in

- Shipping Type Freight

- Item Condition Pre-owned

Sartorius Stedim Biostat B Bioreactor Controller w/ Dual Wave Rocker RM 20/50

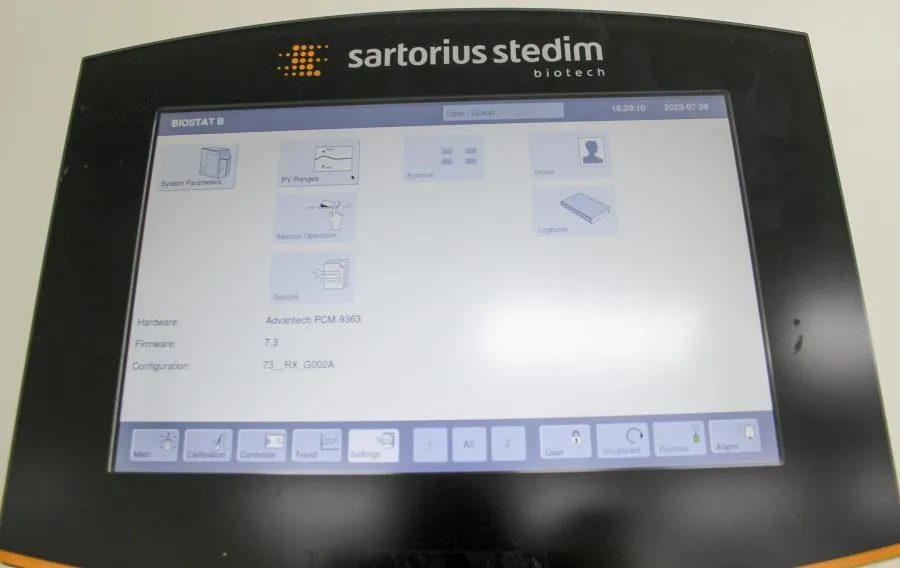

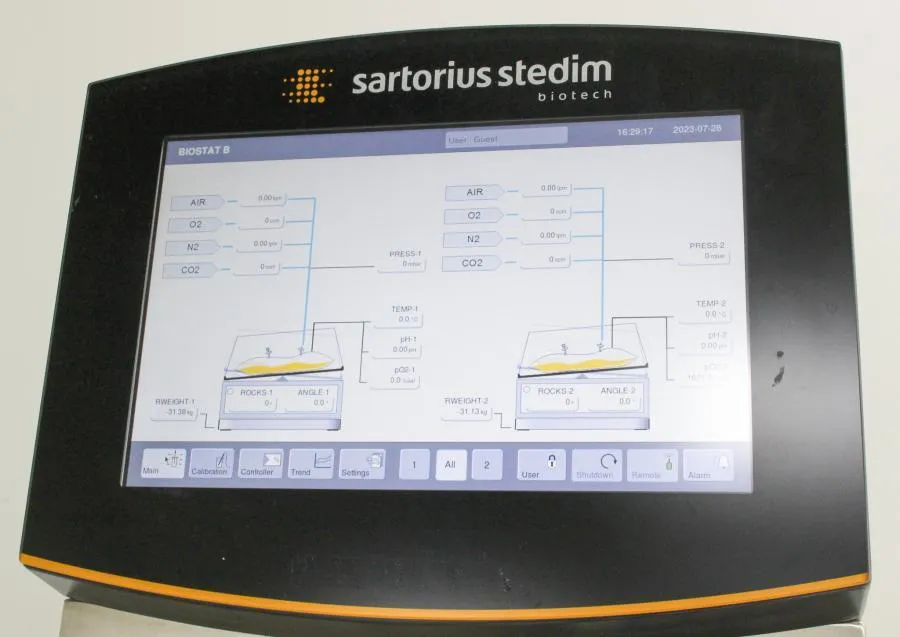

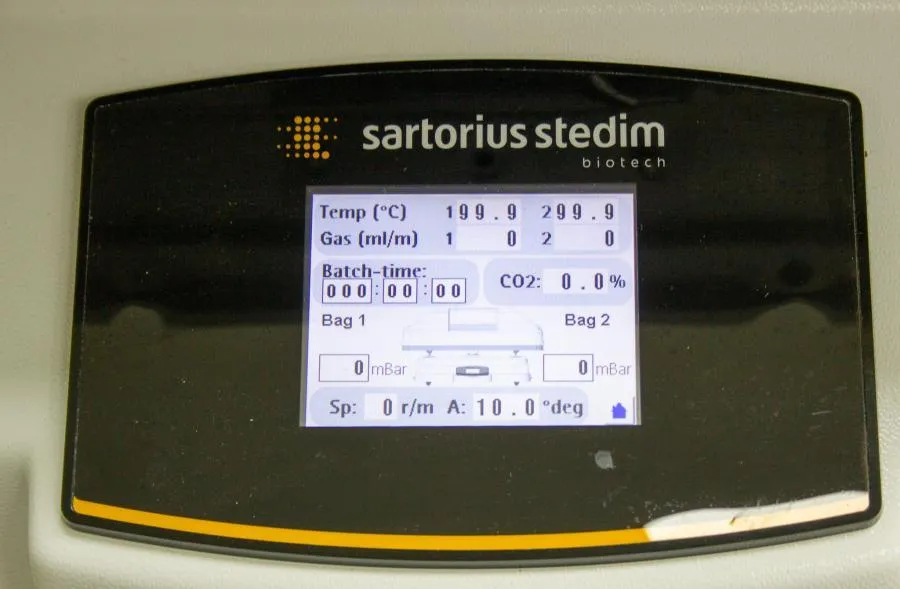

***This unit was tested as far as we could. We are unable to log in to Biostat B Controller due to (We don't have the password to fully test this unit. Units have slight wear from normal use. Buyer can expect the same items pictured with 30-day warranty. See photos for details.

includes:

- Biostat B Bioreactor Controller BB-8821050

- Biostat RM 20/50 I(Qty: 2)

The Biostat® B is a universal benchtop controller for stirred and rocking motion systems. The Biostat® B is a highly flexible and modular system that can be individually adapted to the requirements of your application.

Our Biostat® B is the ideal benchtop bioreactor for your lab. The multi-talented control tower opens up a new world of flexibility for your changing requirements. Use it as single or twin configuration, chose your cultivation chamber from a proven range of options:

- Conventional stirred tank glass vessels

- Single-use stirred tank vessel Univessel® SU

- Wave-mixed Flexsafe RM bags

Applications

- Process development and optimization

- Scale-up and scaledown studies

- Seed expansion

- Cell bank production

- Protein supply

Industries

- Biopharmaceuticals

- Vaccines

- Cell therapies

- Industrial biotechnology

- Basic research

- Education

Biostat® B - Top Features

Designed to meet your specific needs, Biostat® B covers a wide range of applications, extending from use as a flexible basic unit for preclinical research to a fully qualified system that complies with the requirements of a validated GMP environment. You can use our Biostat® B for animal, plant and insect cell cultivation as well as for microbial fermentation.

- Stirred, reusable and single-use culture vessels - all controlled with one DCU tower

- Single or twin set-up for control of one or two culture vessel

- Gassing system comparable to our Biostat STR® with up to four mass flow controller

Engineered for Simplified Scale-Up

Biostat® RM Rocker

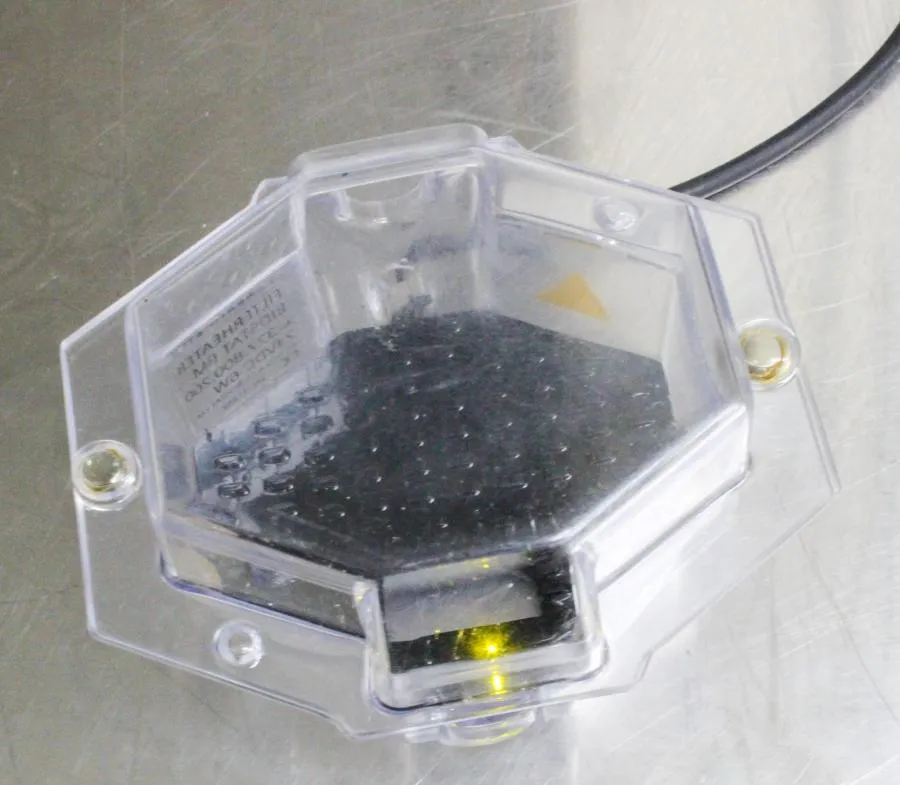

Our proven wave-mixed bioreactor consists of a rocker unit with bag holder and pillow-shaped Flexsafe RM single-use bags for culture volumes from 100 mL to 25 L. Use it as basic system or in combination with the BIOSTAT®B control tower and single-use optical pH and DO sensors to enable advanced control strategies

for batch, fed-batch and continuous perfusion.

Benefits

- Optimized film formula, traceability of raw materials and control of the entire Flexsafe RM bag manufacturing process assure excellent and consistent cell growth of the most sensitive cell lines

- Space-saving, individual control of two nRM bags on the same rocker platform

- Easy-to-use rocker with advanced alarms and safety features for reliable cultivation

The Biostat® RM is a GMP compliant, wave-mixing bioreactor. It is paired with single-use Flexsafe® RM bags and is proven for a broad range of different cell lines incl. CHO, HEK293, stem cells, and CAR-T cells. Especially, customers working with shear-stress-sensitive cell lines and bioconjugates acknowledge benefits of the rocking motion technology.

The modular concept of the Biostat® RM portfolio, ranging from 2 L to our unique 200 L, provides flexibility to manage your individual process needs. Biostat® RM saves space, reduces costs, and increases yields. In addition, Biobrain® - the commercial manufacturing-ready automation platform shared between Biostat® RM and Biostat STR® - enables a seamless transfer from product development to manufacturing scale. This makes the Biostat® RM an integral part of the intensified seed train.

Biostat® RM System Consists of Three Elements: Control Tower, Rocker & Flexsafe® RM Bags

The BIOSTAT® RM 20|50 basic was designed for the development and optimization of manufacturing processes for the cultivation of cells and microorganisms in single-use systems with low shearing forces. The operation of the bioreactor requires special knowledge in the aseptic area to ensure safe handling of cells and microorganisms. Special handling of cell and microorganism cultures may be required to prevent

biological hazards. This also applies to the disposal of cultures and single-use components.

Modular solution enables flexible work spaces

One rocker platform can be used either with a 20 L or 50 L tray, as well there is a separate 200 L platform. Working volumes range from 100 ml and up to 100 L with Flexsafe® RM bags (e.g., basic, optical, or perfusion configurations)

- Biostat RM® Rockers are available in different versions: Biostat® RM 20|50 or Biostat® RM 200

- Wave-motion provides optimal environment for suspension cell culture.

- Weight measurement integrated in rocker

- Monitors the fill level of bag precisely, even during rocking

- Space-saving

Single | Twin ~ 40|55 kg (88 | 121 lbs.)

Control Tower Dimensions (W + H + D)

Single | Twin 410 + 810 + 520 mm (16“ + 32“ + 20“)

Utility Connections

Power supply

– 230 V (± 10%), 50 Hz, max. power consumption 10 A

– 120 V (± 10%), 60 Hz, max. power consumption 12 A

– Potential equalisation

International protection rating IP21

Gases

– Gas supply pressure, 1.5 barg

– Dry, oil and dust-free

– Hose barb for tubing, external dia. = 6 mm

Water

– Water supply pressure, 2–8 barg

– Flow rate up to 20 lpm

– Temperature min. = 4°C

– Discharge pressure-less

– Hose barb for tubing, external dia. = 10 mm

– Degree of hardness: 12 dH max.

Control Tower

Housing Stainless steel, AISI 304

Display Touch screen, 12”, glass, capacitive

Resolution 125 dpi

SCADA communication Industrial Ethernet

Potential-free (common) alarm contact •

Safety valve gas pressure 1 bar (14.5 psi) for UniVessel®

Glass and SU|100 mbar for RM

Water inlet pressure reduction 1.5 bar (22 psi), integrated pressure control

Motor Drive (Univessel®

Glass|SU)

Maintenance-free, quiet direct drive Power: 200 W

Maintenance-free top drive with

magnetic motor coupling Power: 200 W

Rotation speed motor, direct coupling

1L: 20–2,000 rpm

2L: 20–2,000rpm

5L: 20–1,500rpm

10L: 20–800 rpm

2L SU: 20–400 rpm

Rocker Platform

Power supply – 230 V (± 10%), 50 Hz, power consumption 10 A

– 120 V (± 10%), 60 Hz, power consumption 12 A

Power consumption 600 W

International protection rating IP23

Rocking speed 8–42 ± 1 (r/min)

Rocking angle 4–10 ± 0.3 (°)

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”