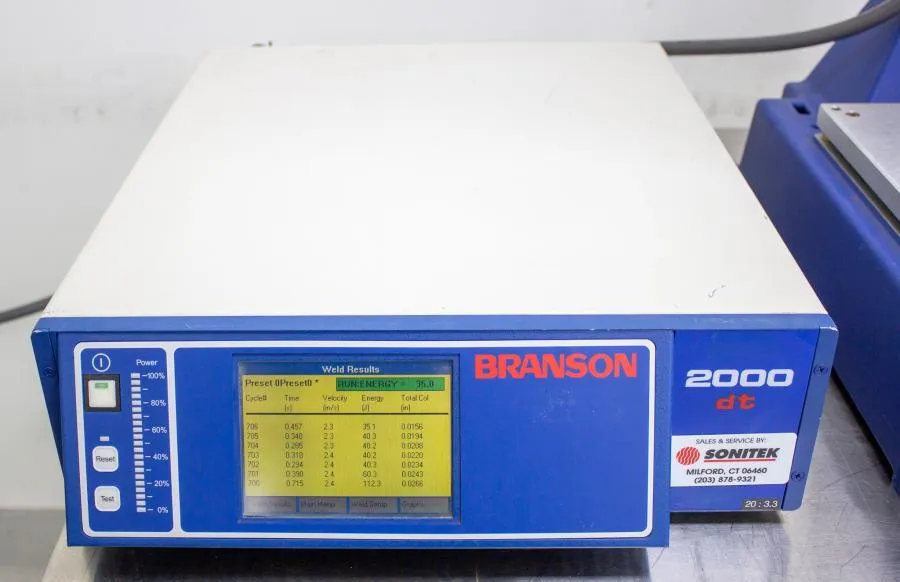

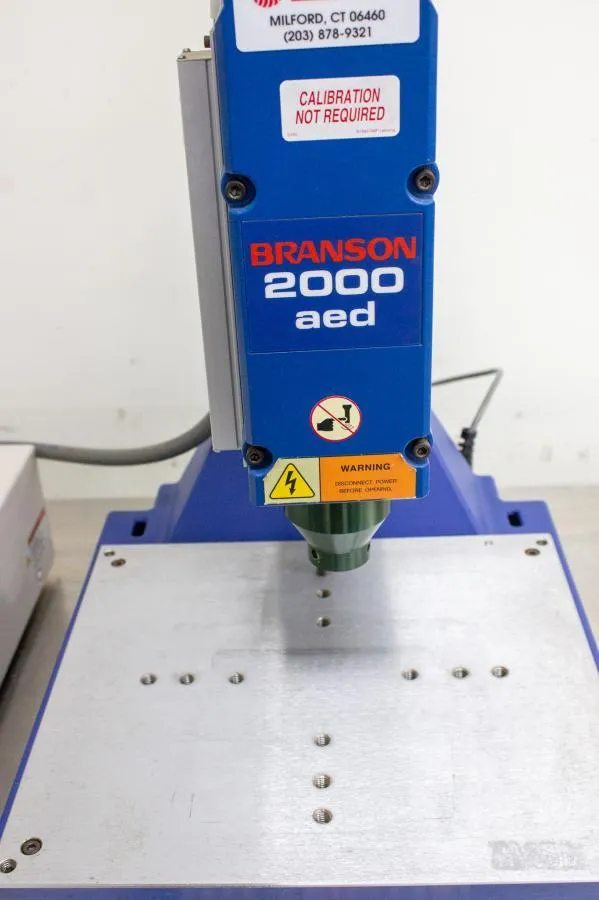

Branson Ultrasonic Welding System 2000AED Actuator w/ 2000DT Power Supply

- Make Branson

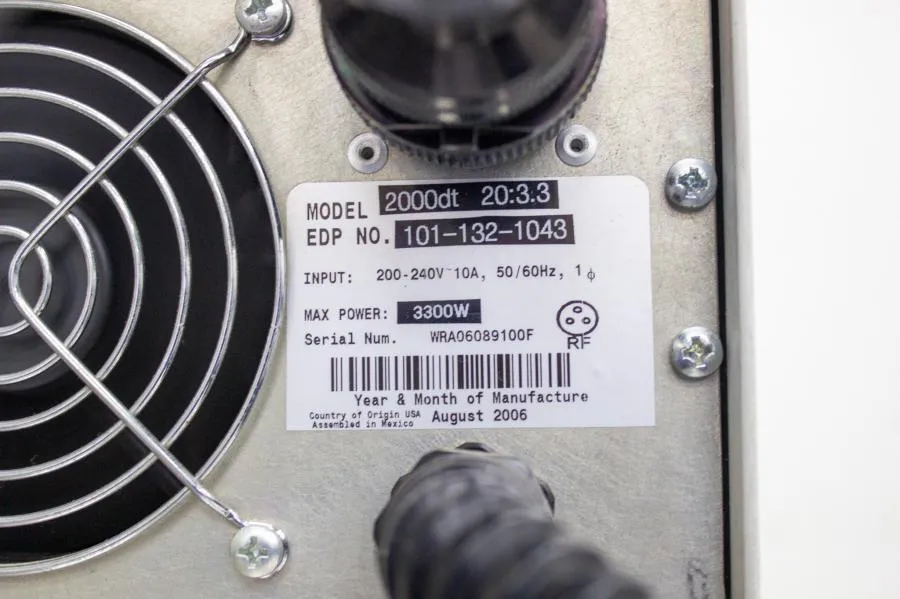

- Hertz 50Hz/60Hz

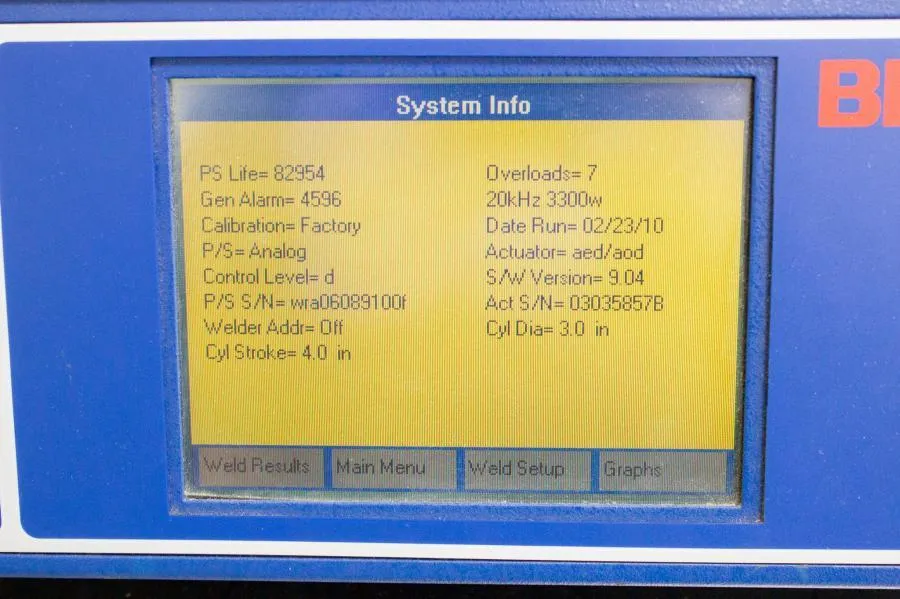

- Model Actuator 1.5 AED & 2000 DT

- Serial WBA03035857B

- Weight 270

- Voltage 220V

- Working Working

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 31×38×51 in

- Shipping Type Freight

- Item Condition Pre-owned

Branson Ultrasonic Welding System 2000AED Actuator w/ 2000DT Power Supply

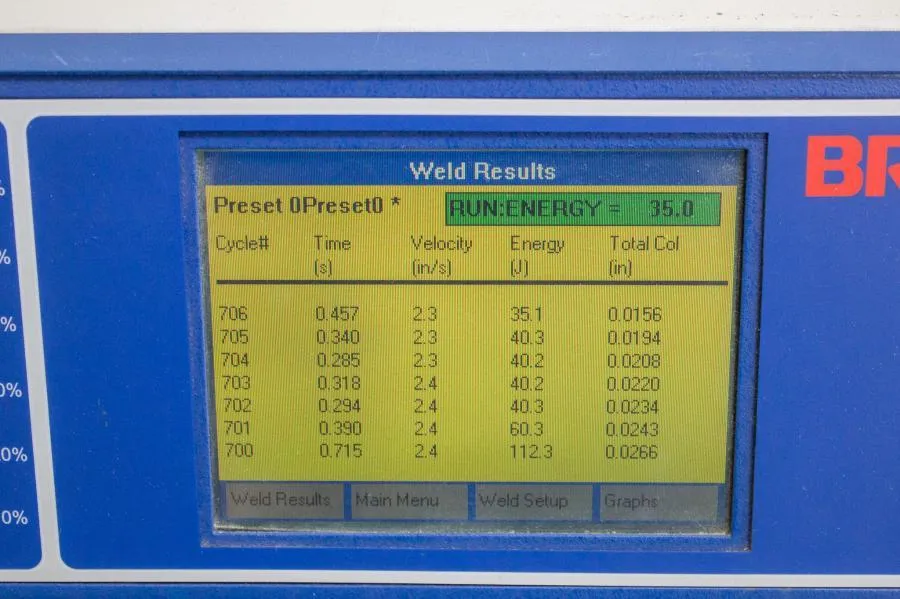

**This ultrasonic welding system was tested as far as we could and is able to power on with all functions working. Unit has slight wear from normal use. Buyer can expect the same unit pictured and 30-day warranty. Everything pictured included. See photos for details.

Ultrasonic plastic welders are fast and efficient machines that create a strong, clean, and hermetic seal without the use of consumables. Their advanced welding technology helps manufacturers increase recyclability, reduce packaging material and eliminate chemical adhesives and solvents. Branson's ultrasonic plastic welding machines are essential to the assembly of automotive products, textiles, medical devices, electronics, and many household items. Branson's benchtop, hand-held, and specialized welding systems and automation components can help you increase production without any compromise in product quality.

Ultrasonic Welders are used in the joining of two or more thermoplastic parts through the precise control of vibration, which generates friction between the parts, achieving a uniform bond between the parts. Ultrasonic can also be used to in joining non-ferrous metals to create a strong weld without the use of applied heat or electric current.

The 2000 series Power Supply and Actuator are components of an ultrasonic welding system. These are designed for a wide variety of welding or processing applications.

Branson 2000 series systems offer varying process control levels and functionalities to match your application needs. In addition, the systems power supply offers multiple weld mode control levels such as (time, energy, peak power, distance, and ground detect), four output ultrasonic frequencies (20, 30 or 40kHZ), and the flexibility to combine with one of several actuator options to create an ultrasonic assembly system that reflects the precise level of performance control and value your application needs.

Standard features on all Branson actuators:

- Variable Dynamic Triggering – Provides consistent weld quality by triggering ultrasonic vibrations after a preset force. As melting of the plastic occurs, dynamic follow-through ensures the smooth, efficient transmission of ultrasonic energy into the part by maintaining horn/part contact and force.

- Rigidity – Further enhanced with three mounting points on the back plane of the actuator. Additionally, the

optional fixed actuator support for column mounting is designed to solidly support the assembly. - Built-In, Adjustable Locking Mechanical Stop with Adjustable Knob – When properly set, the stop prevents.

the horn from touching the fixture or nest when no workpiece is in place. The stop may also be used to control depth of weld or final part height. It is internal to the carriage with only the adjustment knob exposed, allowing 360° horn rotation without interference for alignment.

if required. - Ease of Setup and Changeover – The converter/booster/ horn stack is easily installed and removed from the front of the carriage assembly without repositioning the actuator. The stack may be rotated a full 360° in the carriage for horn alignment with the workpiece.

- Settable Pressure and Down Speed

- Cast Aluminum Carriage Door

- Single-turn Flow Control – Allows for accurate down speed setting and easier resetting during application changeover.

- Dynamic Triggering and Follow Through – Provides consistent weld quality and smooth, efficient transmission of ultrasonic energy by maintaining horn part contact.

- Enhanced Ergonomics – Offers easy access to actuator controls with improved visibility.

- 1.5", 2.0", 2.5", and 3.0" Diameter Cylinders

- Configuration Flexibility – May be operated vertically, horizontally, or inverted.

Models aed, aod, and aodl offer enhanced standard features

- S-Beam Load Cell – Provides precise trigger setting in pounds or Newtons, and displays.

all force data in weld graph. - Distance Encoder (aed, aod, and aodl) – Allows for setting absolute and collapse distance with maximum.

precision, while displaying collapse distance and velocity in weld graphs.

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”