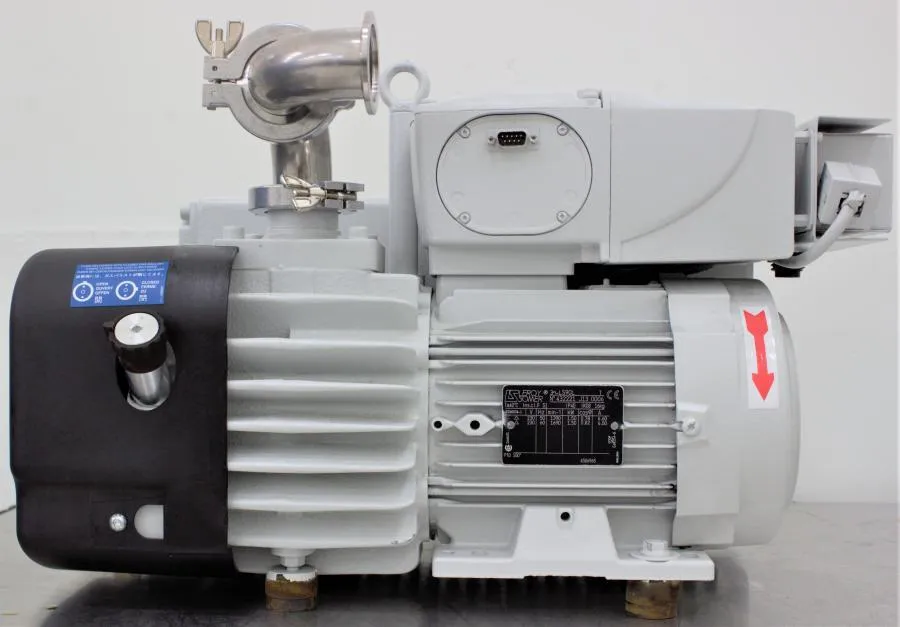

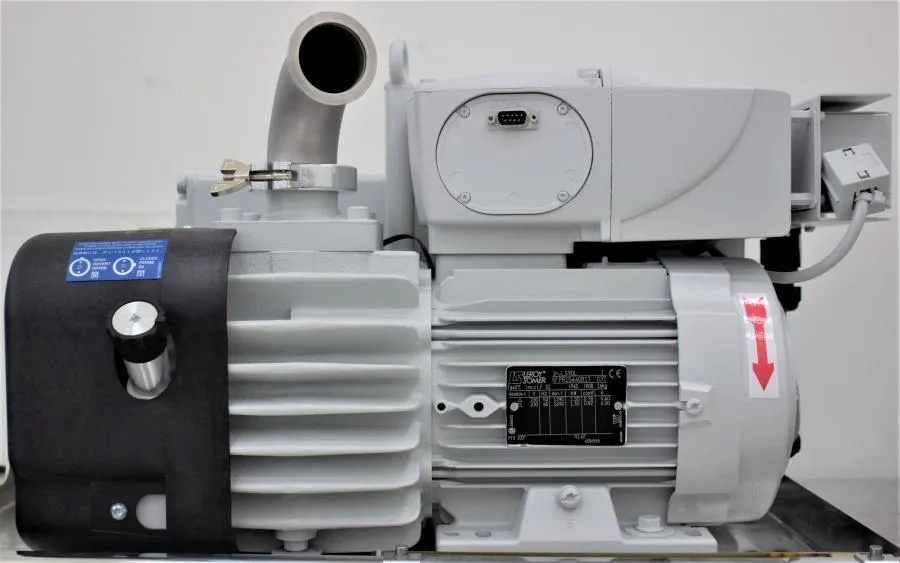

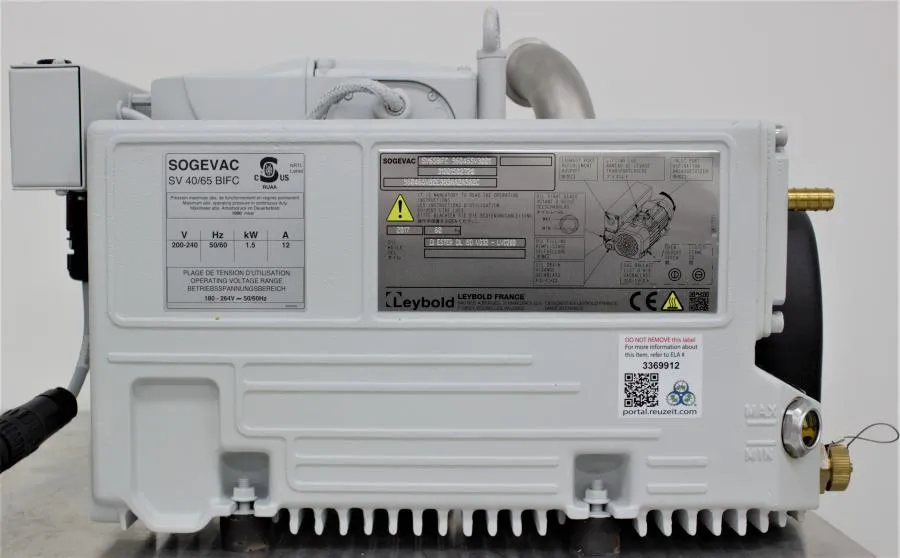

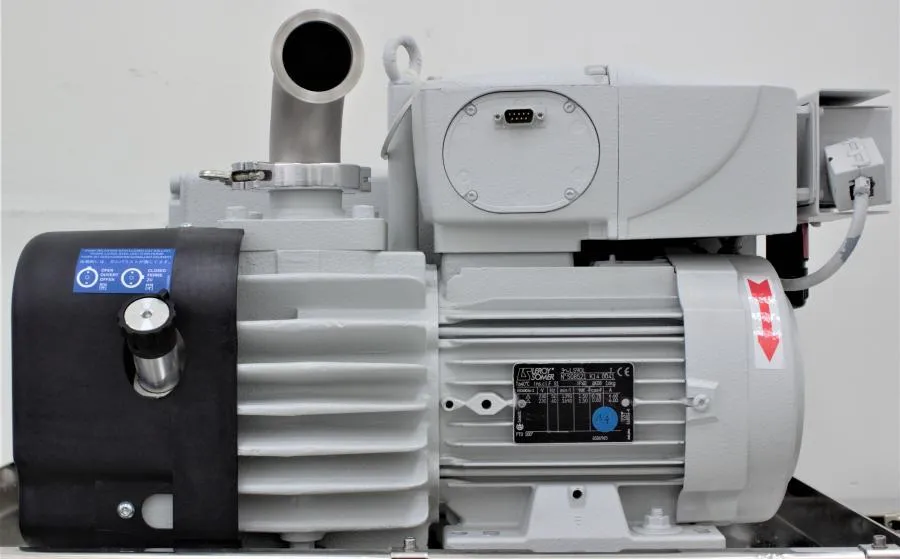

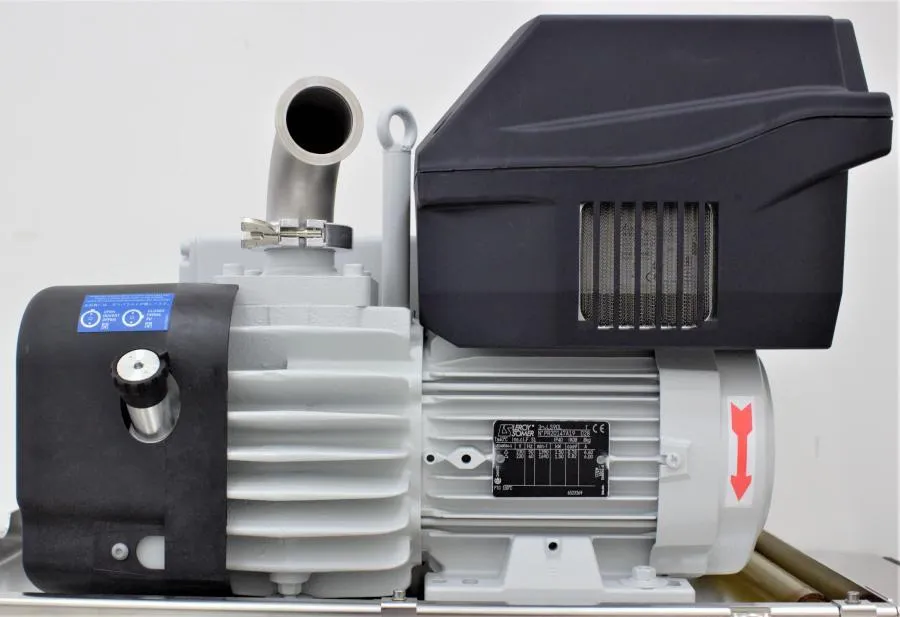

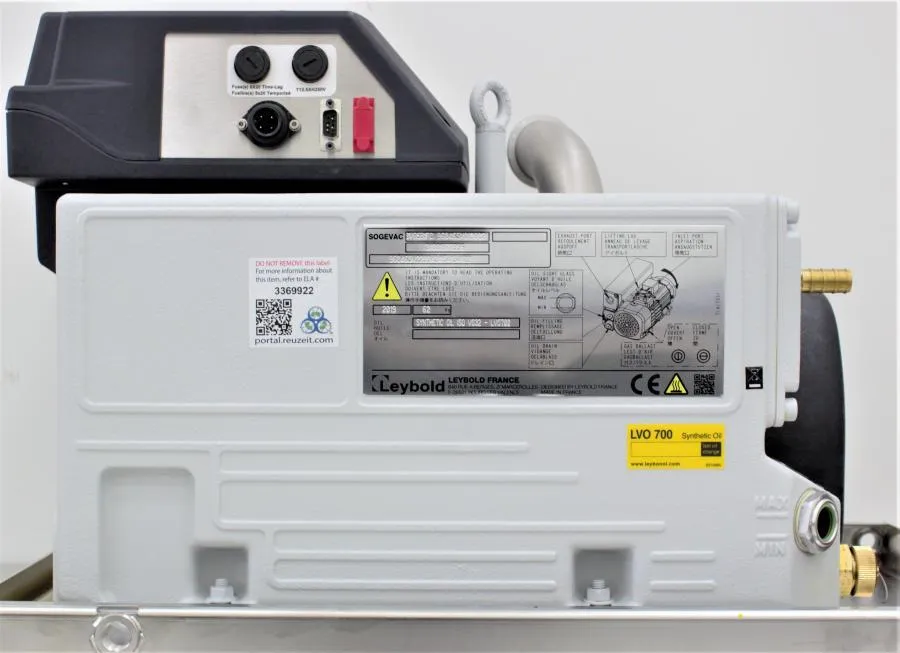

Sogevac SV40-65 BI FC Single-stage, oil-sealed rotor vacuum pump

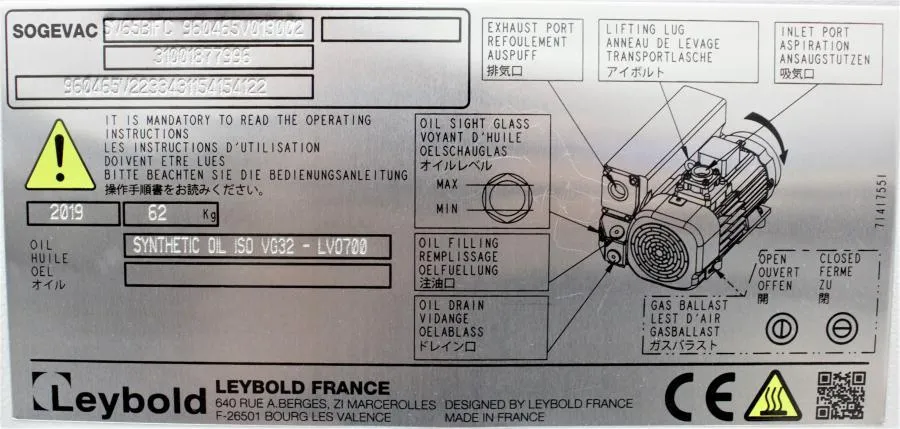

- Make Sogevac

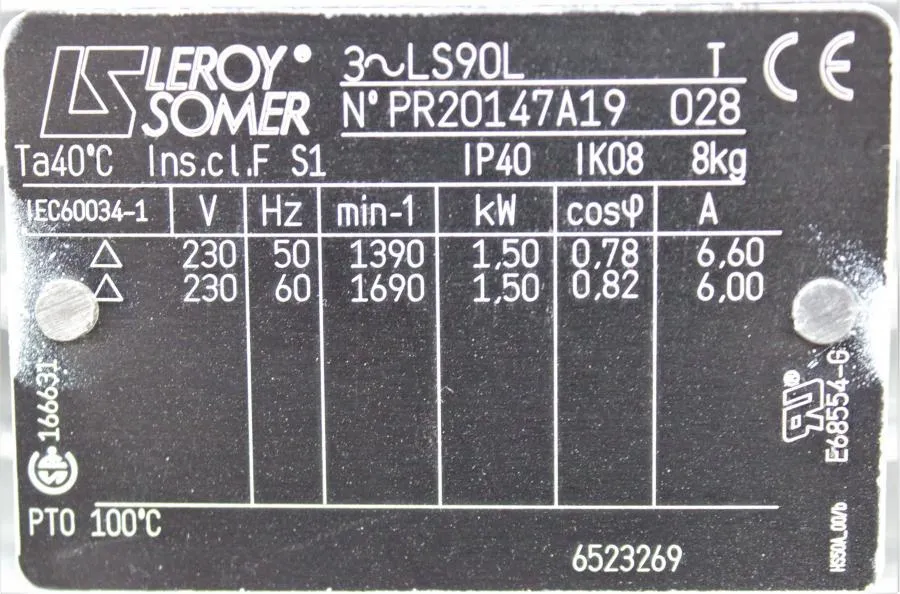

- Hertz 50Hz/60Hz

- Model SV40-65 BI FC Single-stage, oil-sealed rotary vane pump

- Serial PR20147A19

- Weight 65

- Voltage 220V

- Working Working

- Includes Power Cord

- Warranty AS-IS

- Dimensions 28×20×22 in

- Shipping Type FedEx Ground

- Item Condition Pre-owned

Sogevac SV40-65 BI FC Single-stage, oil-sealed rotary vane pump

**Unit has been tested to specifications. Unit was measured and reached a vacuum gauge level of 0.064mBar. This unit achieved that reading but proceeded to fall a bit lower down to 0.096mBar about 20 minutes later. Unit was powered on and tested with very quiet operation. This Unit is attached to a metal oil pan that was screwed into the cabinet it came in. Pump can be removed from the oil pan upon request. Unit shows some minor signs of cosmetic wear on the exterior casing of the pump... please see photos for more details.

Description

Sogevac® pumps are designed for pumping of inert gases in the range of rough.

vacuum, between atmospheric pressure and ultimate pressure of the pump.

When removing condensable vapors, periodic opening of the gas ballast valve

is required.

1.1 Principle of operation (Manual)

The Sogevac® pumps are single-stage oil-sealed rotary vane vacuum pumps.

The rotor, having three slots in which the vanes are sliding, is eccentrically.

installed in a pump cylinder (stator). The vanes separate the interior space into 3 chambers. The volume of these chambers varies with the rotation of the rotor.

The gas sucked into the inlet chamber is compressed and then pushed out at

the exhaust valve. The oil injected in the inlet chamber guarantees the airtightness, the lubrication and cooling of the pump. It is dragged off by the compressed.

gases and roughly separated by gravity when entering in the oil sump. A fine

separation is then operated in the exhaust filter. An internal transfer push the

collected oil back into the vacuum generator, the transfer is operated by a float.

valve to avoid atmospheric air coming from the oil casing to the inlet of the

pump when no oil is present in the recovery system. The oil circulation functions by differential pressures. The pumps are equipped with a gas ballast valve for pumping condensable vapors. The anti-suck back valve at the inlet flange avoids oil coming back into the inlet line when the pump is stopped. This is valid for working pressures below 100 mbar and under the condition that the valve is kept clean and in good.

condition. The anti-suck-back valve is not a safety valve. If oil back flowing is to

be avoided by all means, it is necessary to mount a separate safety valve on the

pump inlet. Some variants are equipped with a frequency converter giving a constant

pumping speed independently of the mains frequency and regulating

the pump power consumption. At high inlet pressures, the pump speed is.

decreased.

The pump speed can be reduced to 900 rpm (idle mode) to reduce the power.

consumption w/o loss of end pressure on some pump variants. In this idle

mode, the pump inlet pressure must remain below 10 mbar.

Technical Data

SV40 B FC

Technical data 50 Hz & 60 Hz

Nominal pumping speed m3

/h ≥ 53

Pumping speed (according to PNEUROP) m3

/h à 2 mbar ≥ 36

Ultimate partial pressure without gas ballast mbar ≤ 0,2

Ultimate total pressure with small gas ballast mbar ≤ 1,0

Water vapor tolerance:

with small gas ballast approx. mbar 10

Water vapor tolerable load:

with small gas ballast approx. kg.h-1 0,34

Noise level (according to DIN 46 635) dB (A) ≤ 59

Motor power - Rated rotational speed kW - min-1 1,6-1800.

Mains voltage (+/- 10 %) AC ~ V 200 ... 240

Protection - Insulation 1) IP 20 - F

Leak rate mbar. I. s-1 <1 x 10-3

Ambient temperature °C 18 ... 40

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”