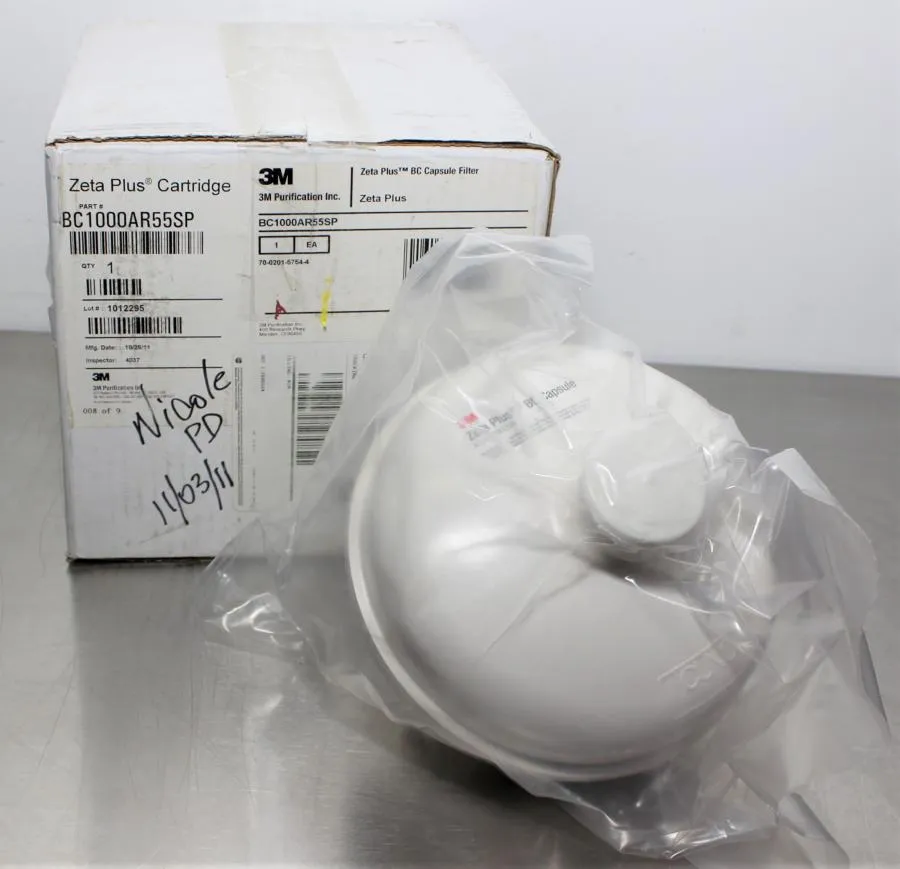

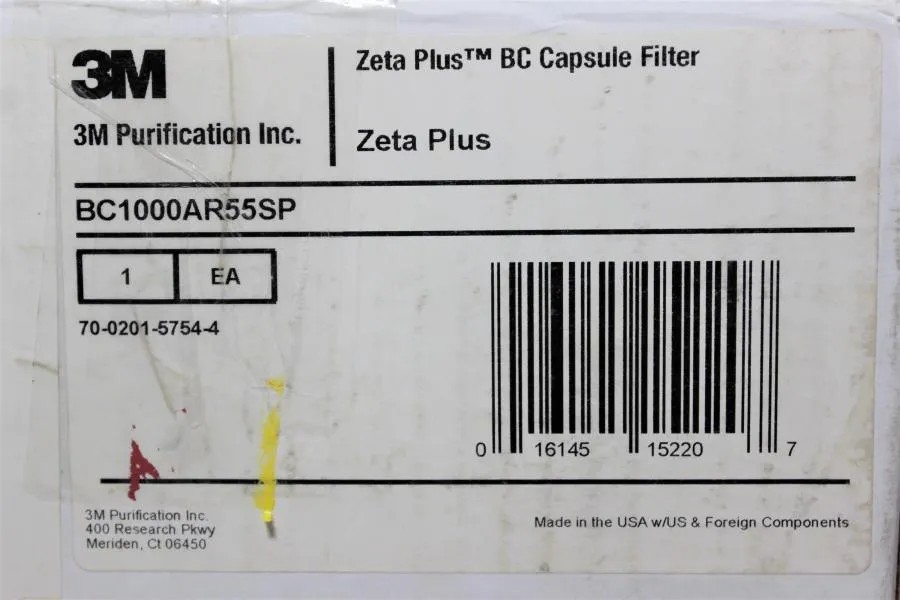

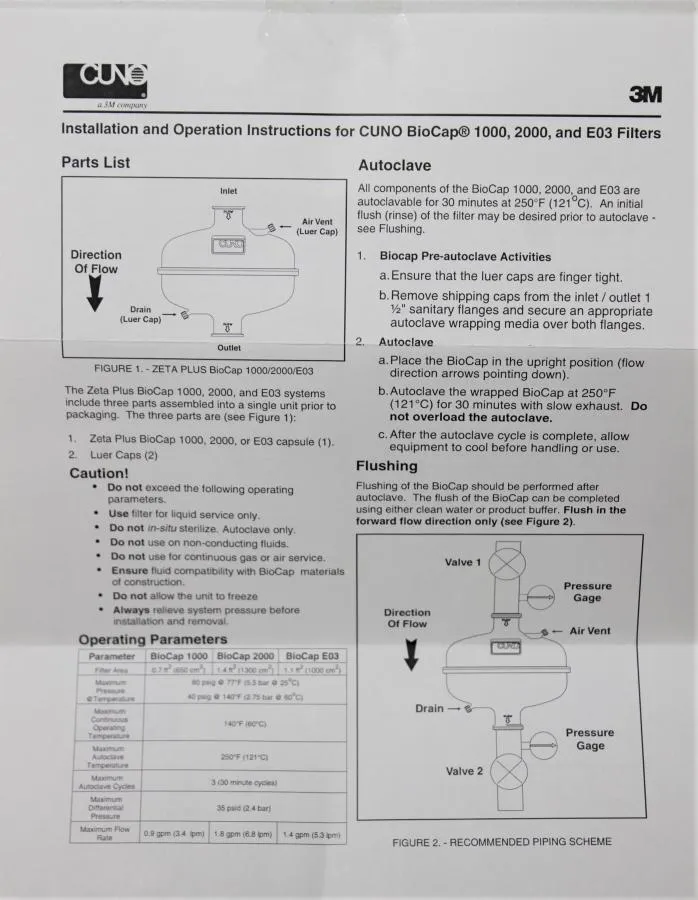

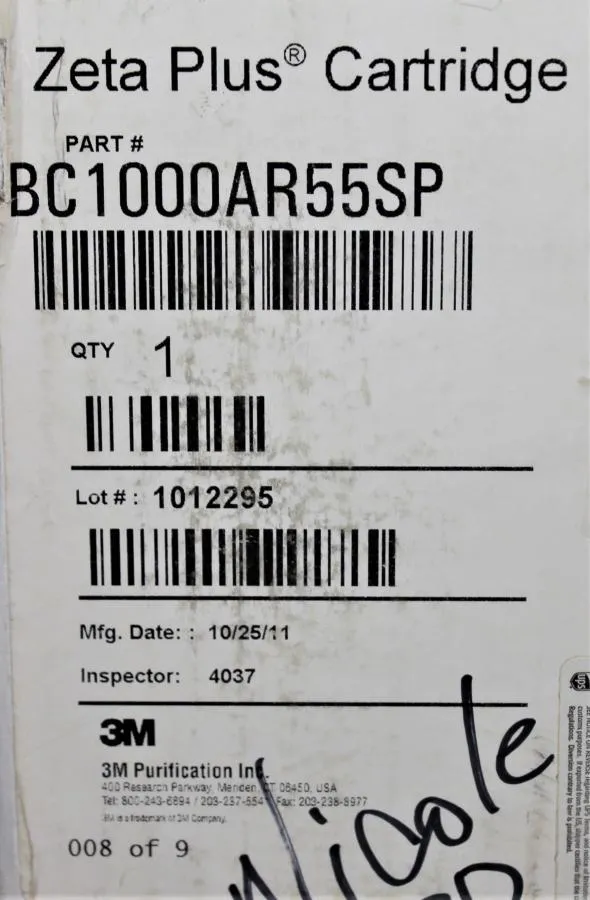

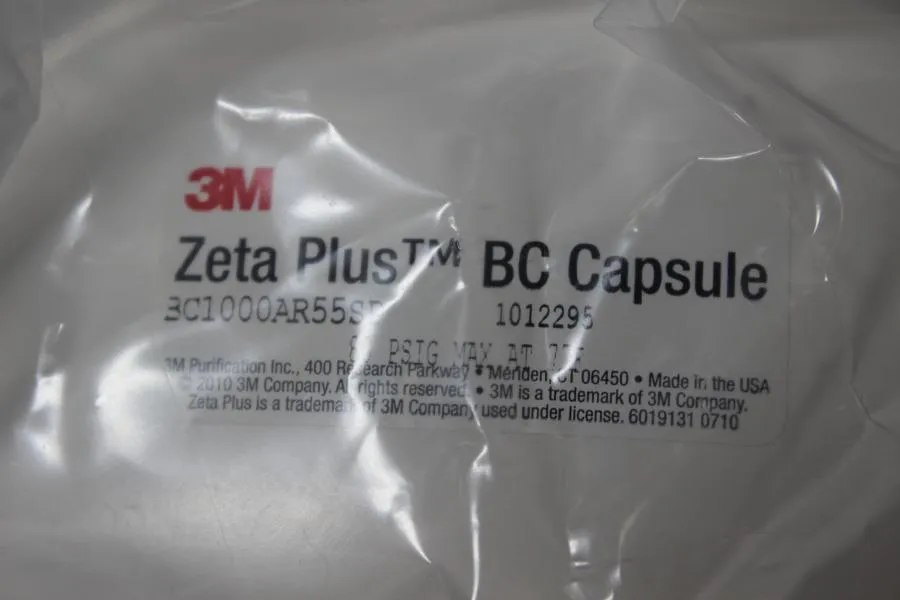

3M Zeta Plus Cartridge BC Capsule Filter BC1000AR55SP

- Make 3M

- Model Zeta Plus Cartridge BC Capsule Filter BC1000AR55SP

- Serial N/A

- Weight 9

- Working Working

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 14×14×16 in

- Shipping Type FedEx Ground

- Item Condition New other (see details)

Activated carbon is a highly porous carbonaceous material that is characterized by a large internal surface area providing exceptional adsorptive properties.

Pores within the structure can be classified into different categories depending on their size: micropores (25 nm). Activated carbon can be produced from different sources such as peat, lignite, pine wood, coconut shell, etc.

The raw material influences the pore structure of the activated carbon; as an example, activated carbon made from pinewood has a wide distribution of micro, meso and macro pores, whereas activated carbon obtained from coconut shell is typically microporous.

Features / Benefits

- Less fire risk and almost no carbon

- After initial flush of the cartridge, there is minimal release of carbon fines in the filtered solution

- Decreased process time because of constant flow rate filtration and efficiency

- No product rework because of consistent performance

- Activated carbon is fixed and the flow is forced through the matrix that increases efficiency

- A single step is used as decolorization is combined with the filtration step Reduced costs in solvent recovery

Operating Conditions

- Maximum Operating Temperature 80° C (176° F)

- Recommended Flow 3 l/min

Typical Applications

- Cosmetics

- Chemicals

- Food & Beverage

- Pharmaceuticals

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”