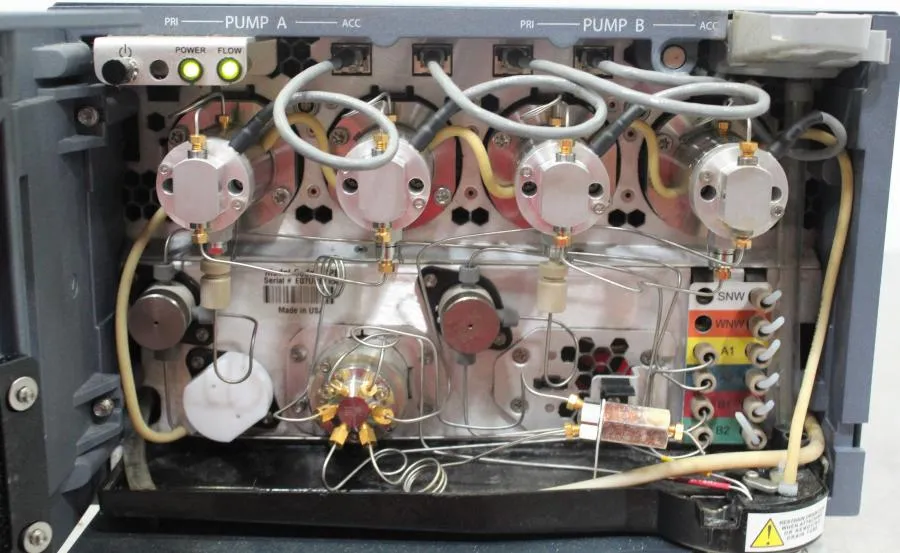

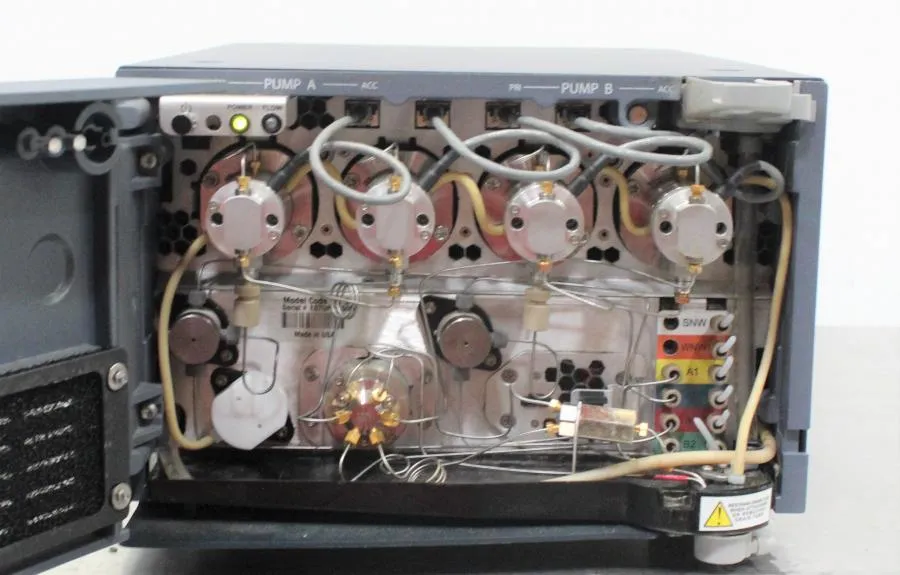

Waters Acquity Binary Solvent Manager

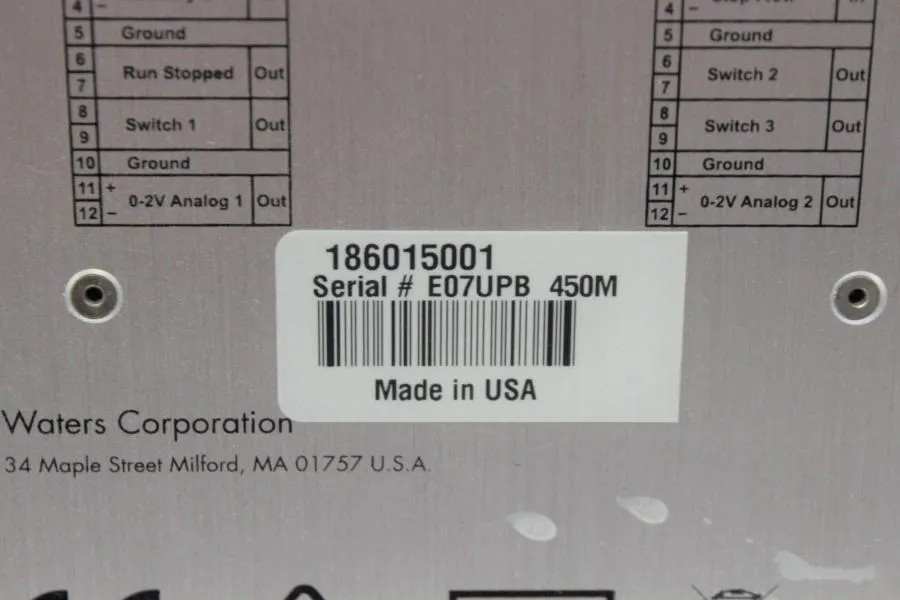

- Make Waters

- Hertz 50Hz/60Hz

- Model 186015001

- Serial E07UPB 450M

- Weight 80

- Voltage 120V/220V

- Working Working

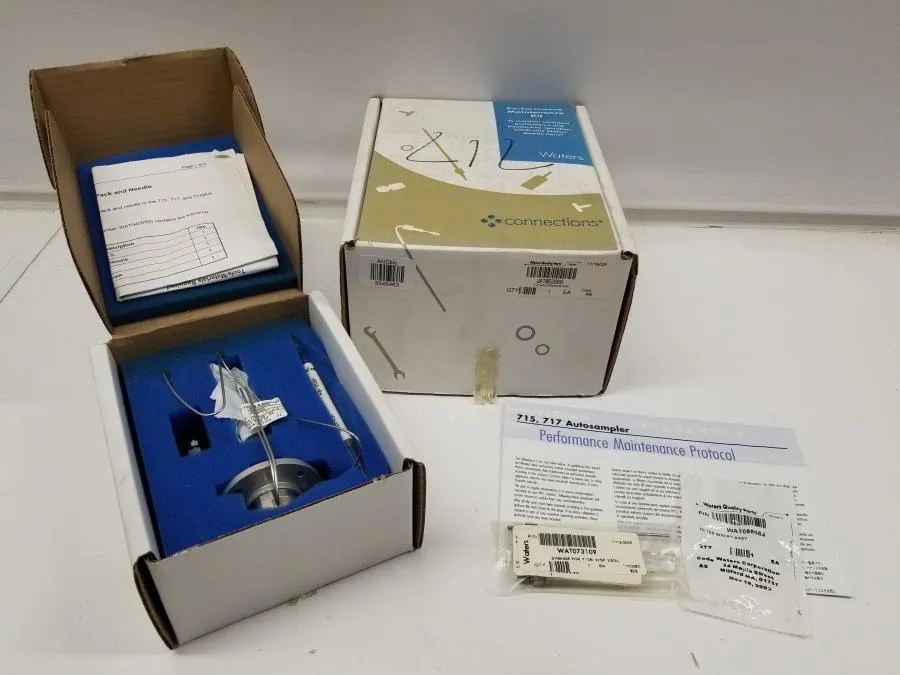

- Includes Power Cord

- Warranty 30-Day Warranty, 100% Parts and Labor

- Dimensions 34×22×18 in

- Shipping Type Freight

- Item Condition Pre-owned

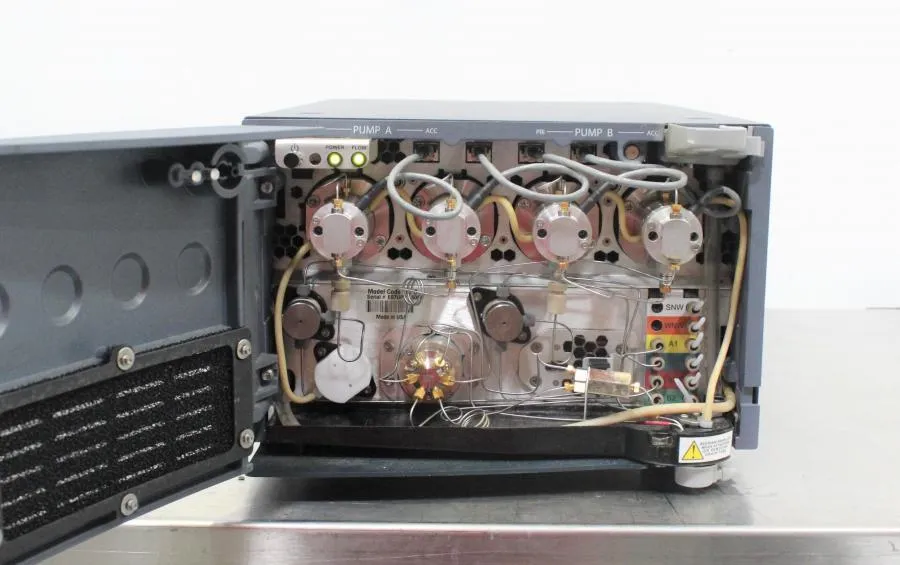

The binary solvent manager is a high-pressure pump that moves solvent through the system. It provides steady (pulse-free) solvent flow at analytical flow rates. The binary solvent manager delivers solvent at flow rates of 1 mL/min at 103,421 kPa (1034 bar, 15,000 psi) and up to 2 mL/min at reduced pressures to 62,053 kPa (621 bar, 9000 psi). The binary solvent manager can pump two solvents simultaneously.

Manufacture Specification

| Number of Solvents | Up to four |

| Solvent Conditioning | Vacuum degassing (six-channel): one channel per solvent, and two channels for Sample Manager wash solvent |

| Operating Flow Range Rate | 0.010 to 2.000 mL/min, in 0.001 mL increments |

| Compressibility Compensation | Automatic and continuous |

| Effective System Delay Volume | < 120 μL, independent of system backpressure (with standard 50-μL mixer installed) |

| Plunger Seal Wash | Integral, active, programmable |

| Gradient Profiles | Eleven gradient curves [including linear, step (2), concave (4), and convex (4)] |

| Wet Prime | Automatic |

| Maximum Operating Pressure | 15,000 psi up to 1 mL/min, 9,000 psi up to 2 mL/min per pump, not more than 15,000 psi total |

| Composition Accuracy | ±0.5% absolute (full scale) from 5 to 95% of flow rates from 0.5 to 2.0 mL/min (Contact Waters for conditions used) |

| Composition Precision | 0.15% RSD or ±0.04 min SD, whichever is greater, based on retention time |

| Flow Precision | 0.075% RSD or ±0.02 min SD, six replicates, based on retention time or volumetric measures (0.500 to 2.000 mL/min) |

| Flow Accuracy | ±1.0% at 0.5 mL/min with degassed methanol, per Waters AQT/SystemsQT protocol |

| Primary Wetted Materials | 316 stainless steel, UHMWPE, sapphire, ruby, FEP, PTFE, ETFE, diamond-like coating, PEEK and PEEK alloys, titanium alloys |

Testimonials

“REUZEit has been a great partner for our used equipment needs and always provide timely updates of new arrivals of consigned equipment.”

“Great company to work with. Tammy completed our first international equipment shipment with ease.”

“Fast response, open to adjusting schedule as needed, and great customer interaction.”